Method for preparing amorphous/amorphous nano multilayer film with improved plasticity

A nano-multi-layer, amorphous layer technology, applied in the direction of coating, superimposed layer plating, metal material coating technology, etc., can solve the problem of reducing the essential characteristics of amorphous alloys, the shear transition zone is not easy to aggregate, and the shear band Difficult nucleation and other problems, to achieve the effect of easy implementation, simple operation, and improved plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

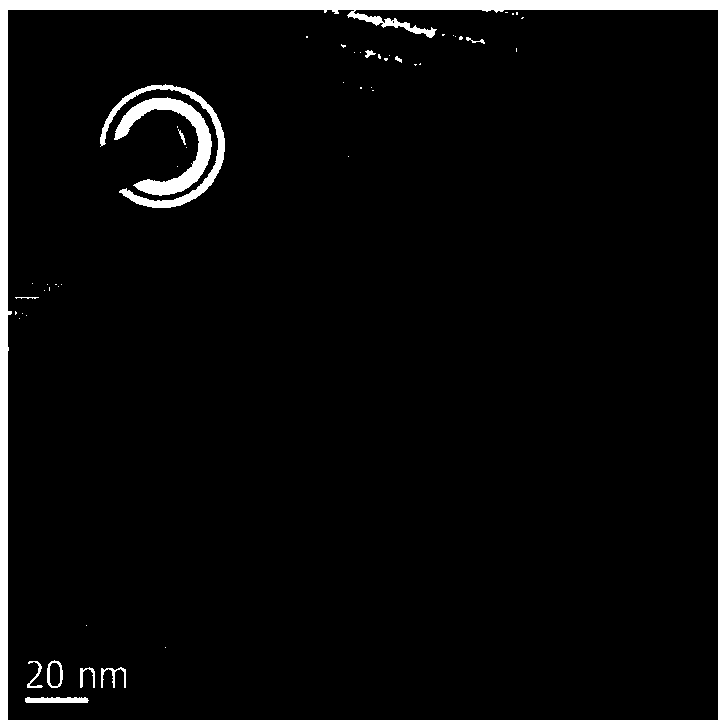

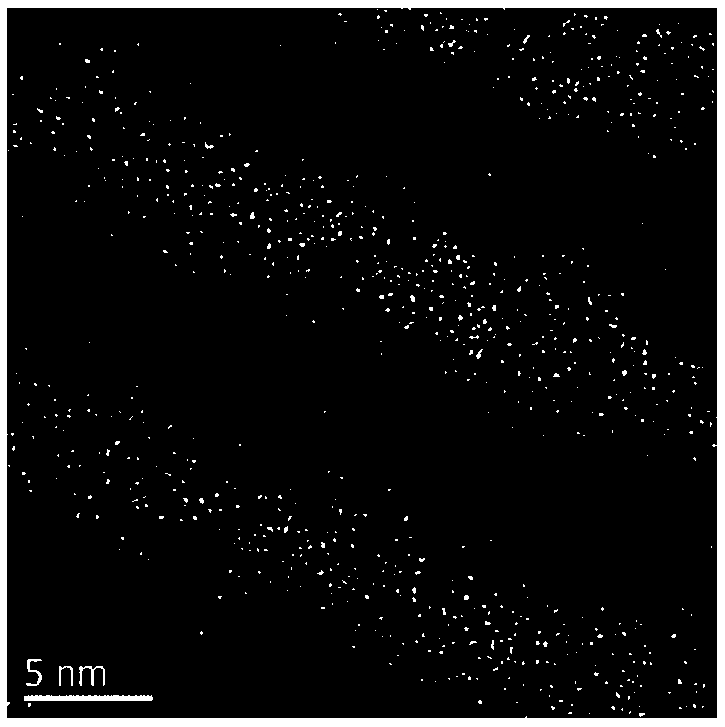

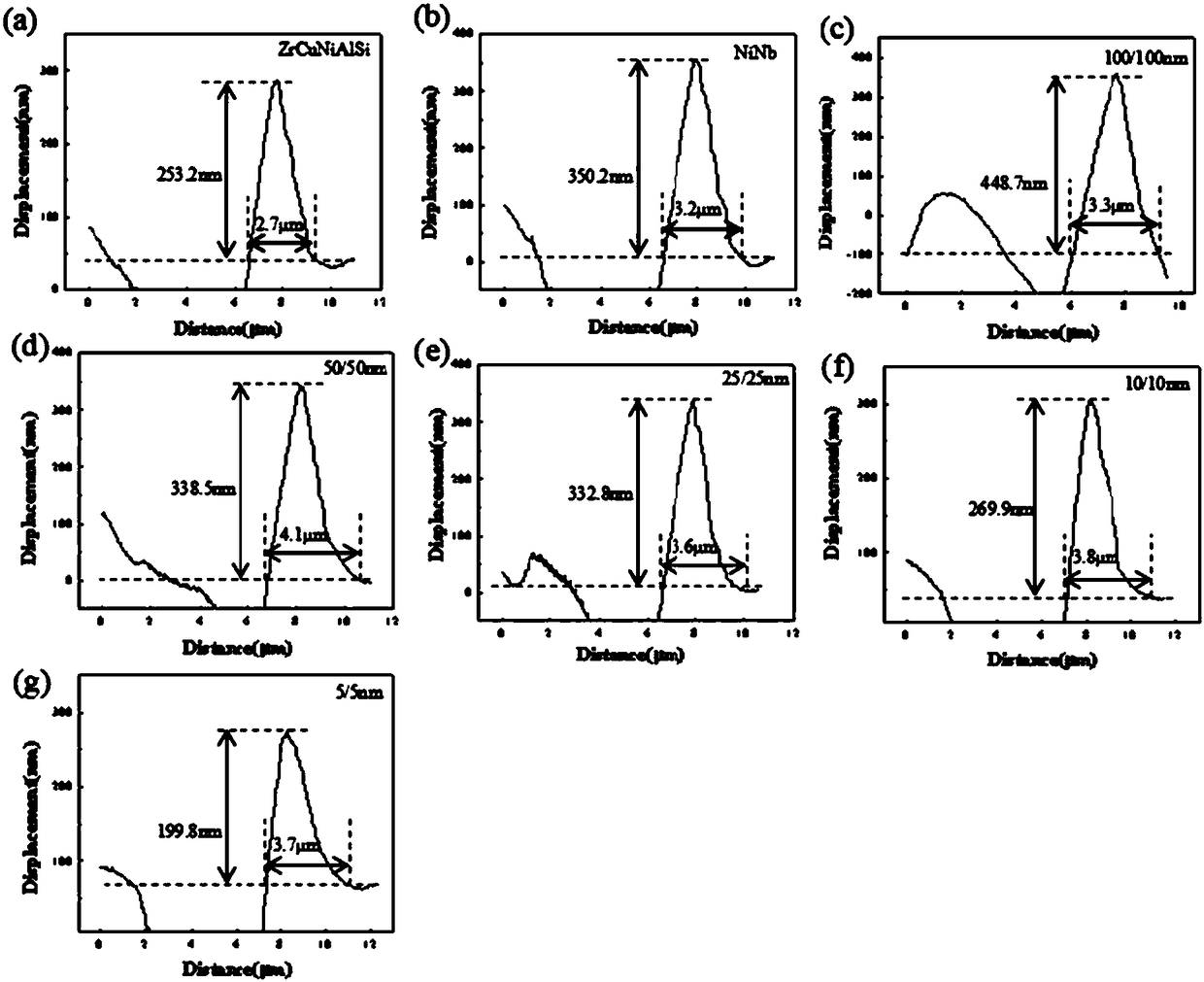

[0027] A kind of method of the present invention prepares the amorphous / amorphous nanometer multi-layer thin film that plasticity improves, is in magnetron sputtering process, adopts slow rate deposition process, changes Ni by controlling sputtering time 50 Nb 50 layer and Zr 61 Cu 17.5 Ni 10 Al 7.5 Si 4 The thickness of the single layer of the layer, the Ni 50 Nb 50 / Zr 61 Cu 17.5 Ni 10 Al 7.5 Si 4 multilayer film. The plasticity of a multilayer film with a single layer thickness of 5 nanometers prepared by this process is significantly improved compared with two single-layer films. It specifically includes the following steps:

[0028] 1) The single-sided polished single-crystal silicon substrate is ultrasonically cleaned with alcohol and acetone respectively, and after being blown dry by a hair dryer, it is placed on the substrate table of an ultra-high vacuum magnetron sputtering device to prepare for coating; in the best embodiment of the present invention I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com