High-impedance broadband soft magnetic ferrite material, magnet ring and preparation process thereof

A soft magnetic ferrite and preparation technology, which is applied in the direction of inorganic material magnetism, inductor/transformer/magnet manufacturing, transformer/inductor core, etc., can solve the problems of high price, unreachable performance, low impedance in low frequency band, etc. , to reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] According to the following weight ratio ingredients

[0024]

[0025] 2. Ball milling and pre-burning magnetic powder

[0026] The raw materials of the above example are sent into a ball mill tank, mixed and ball milled, the process conditions are controlled by weight ratio steel ball: raw material: deionized water=3:1:1, the ball milling time is 5 to 6 hours, and the material is dried after discharge.

[0027] The powder is pre-fired at a temperature of about 1000 ° C for 4 to 5 hours.

[0028] Put the pre-burned powder into the ball mill tank again for ball milling, the process conditions are controlled according to the weight ratio of steel ball: raw material: deionized water = 3:1:0.7-0.9, the ball milling time is 19-20 hours, and the material is dried after discharge.

[0029] 3. Sintered magnetic ring

[0030] The powder is made into an inductor magnetic ring according to the traditional ceramic process, and it is sintered in the air for 5-6 hours, a...

PUM

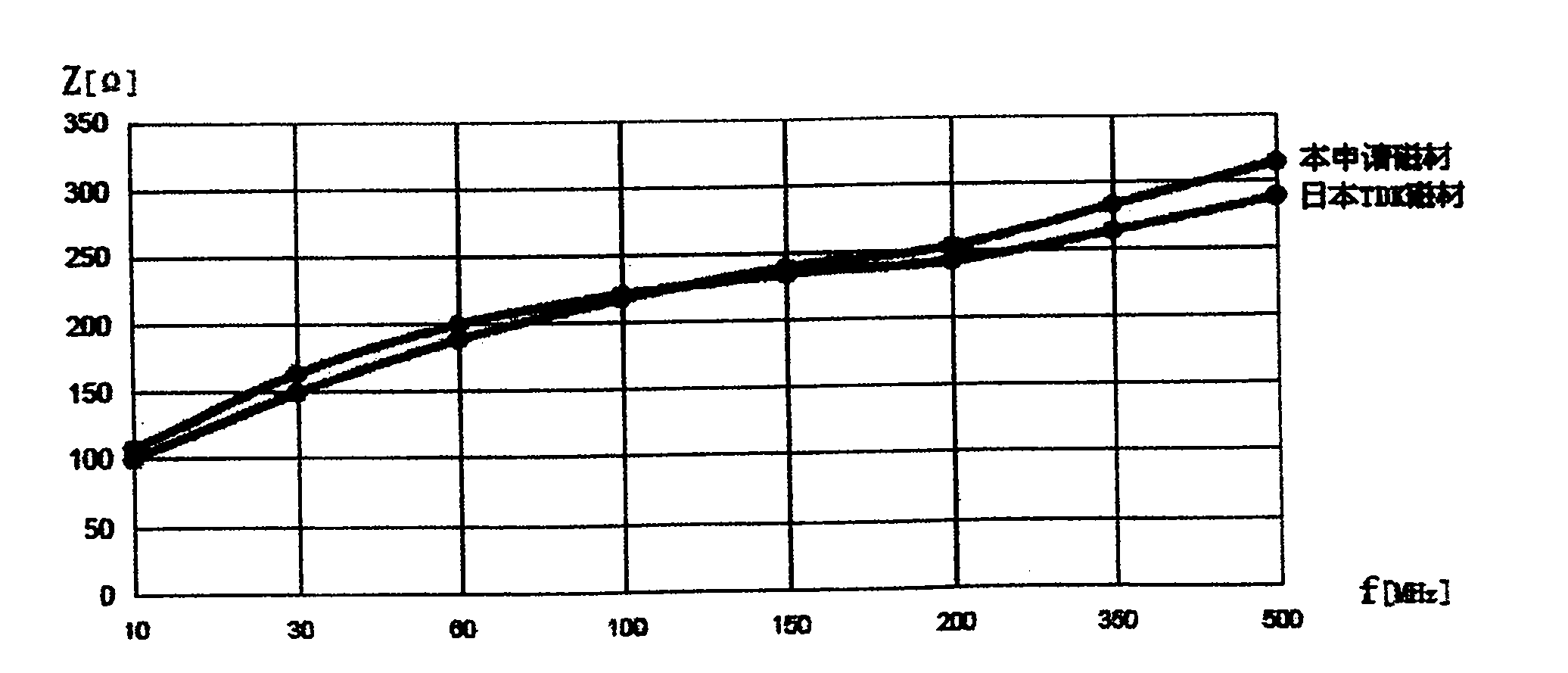

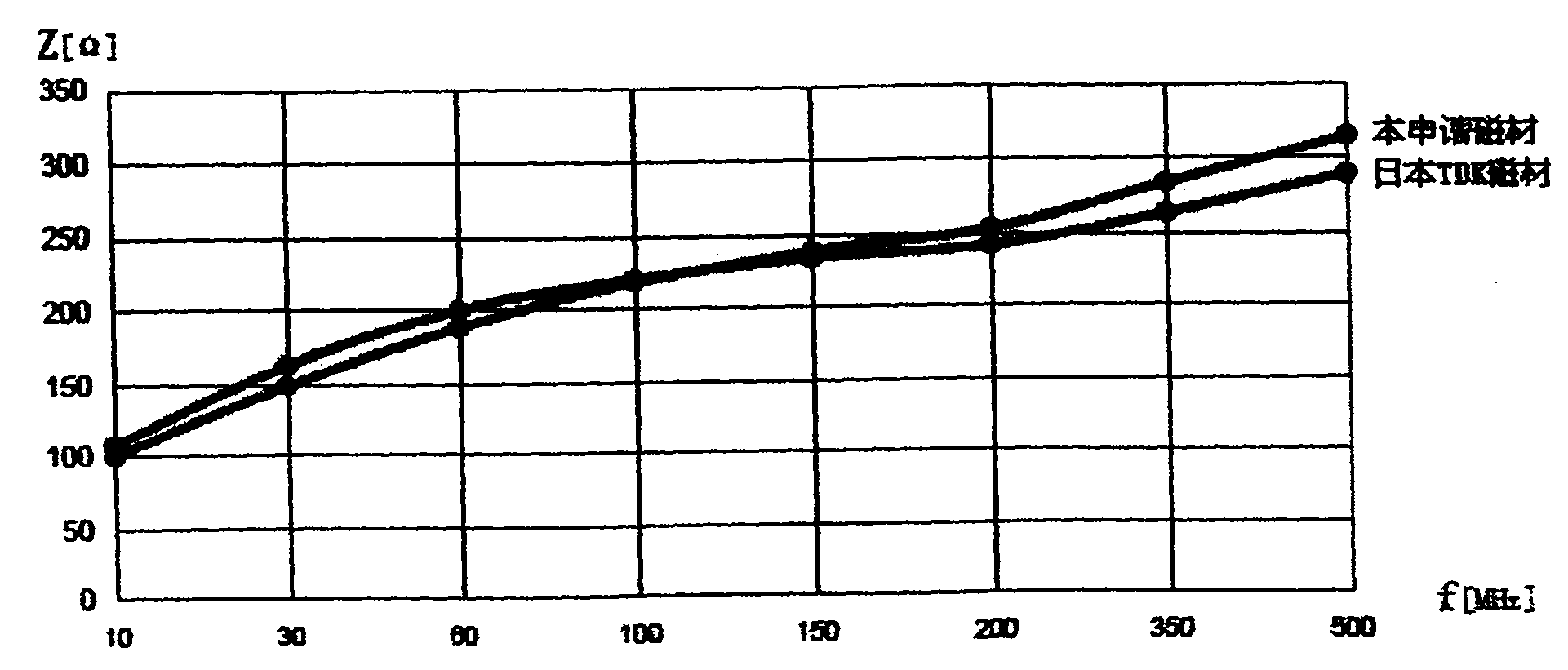

| Property | Measurement | Unit |

|---|---|---|

| impedance | aaaaa | aaaaa |

| impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com