Skin material for skin-integrated foam molding

A foam molding and skin material technology, which is applied in the field of skin materials for integral foam molding of the skin, can solve problems such as skin material wrinkles, and achieve the effects of ensuring air permeability, preventing hardening, and preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

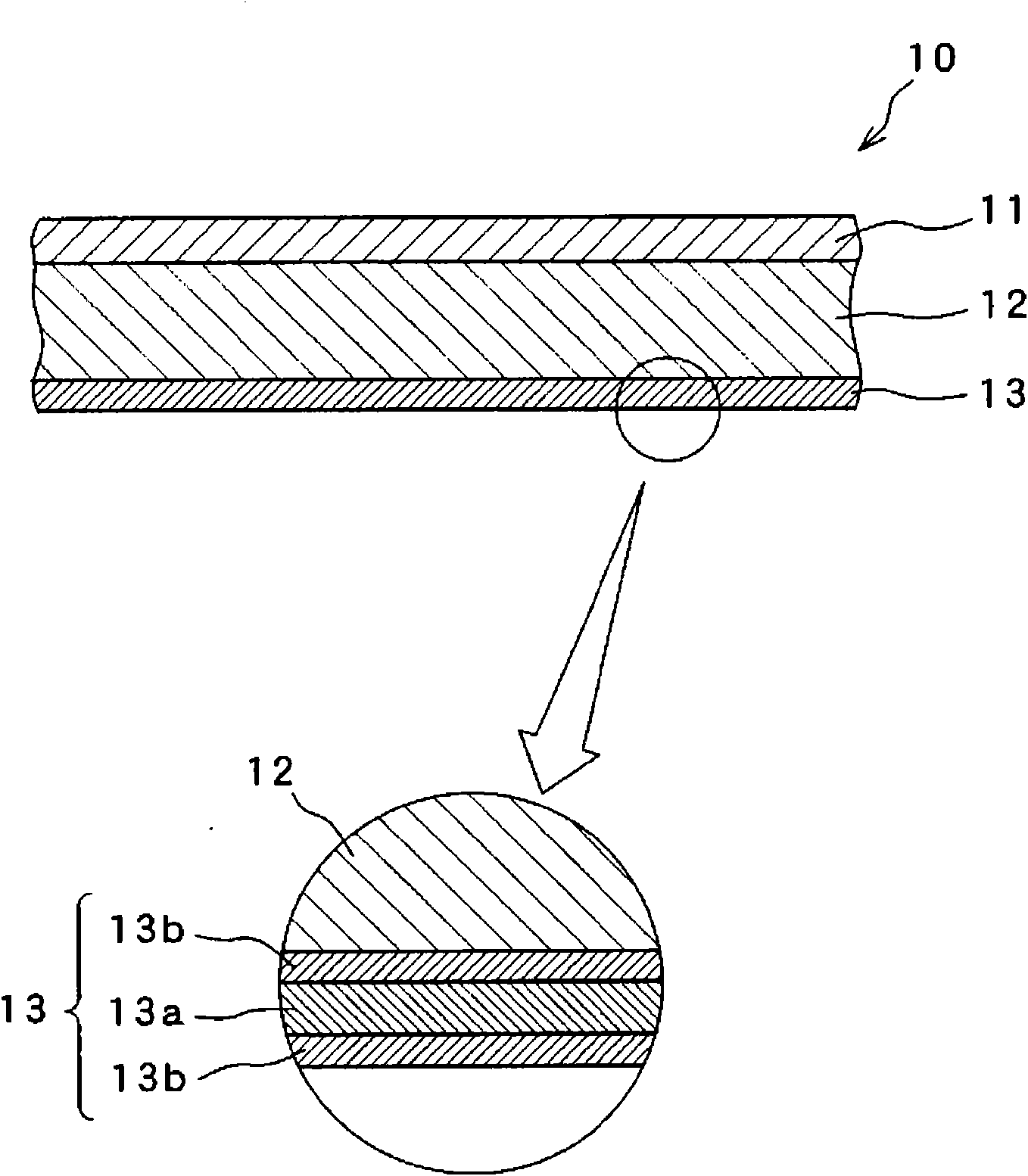

[0076] (Example 1) Evaluation sample: A nonwoven fabric using a 2-layer laminate having an average weight per unit area of 25 g / m by hot embossing 2 Styrenic elastomer resin melt-blown non-woven fabric (second layer) (SEPS, average fiber diameter 4.5μm) on one side, heat-pressed with an average weight per unit area of 20g / m 2 A two-layer laminate of a melt-blown nonwoven fabric (first layer) composed of polybutylene terephthalate (PBT, average fiber diameter 3.5 μm).

[0077] The measured values of this nonwoven fabric are shown in Table 1, and the air permeability (JIS-L1096) is 12.5cc / cm 2 / s, water pressure resistance (JIS-L1092) is 529mmH 2 O. The average value of pore size (valve point method based on ASTMF-361-80, automatic pore measuring device for porous materials, Perm Porometer POROUS MATERIALS, INC.) is 12.1 μm.

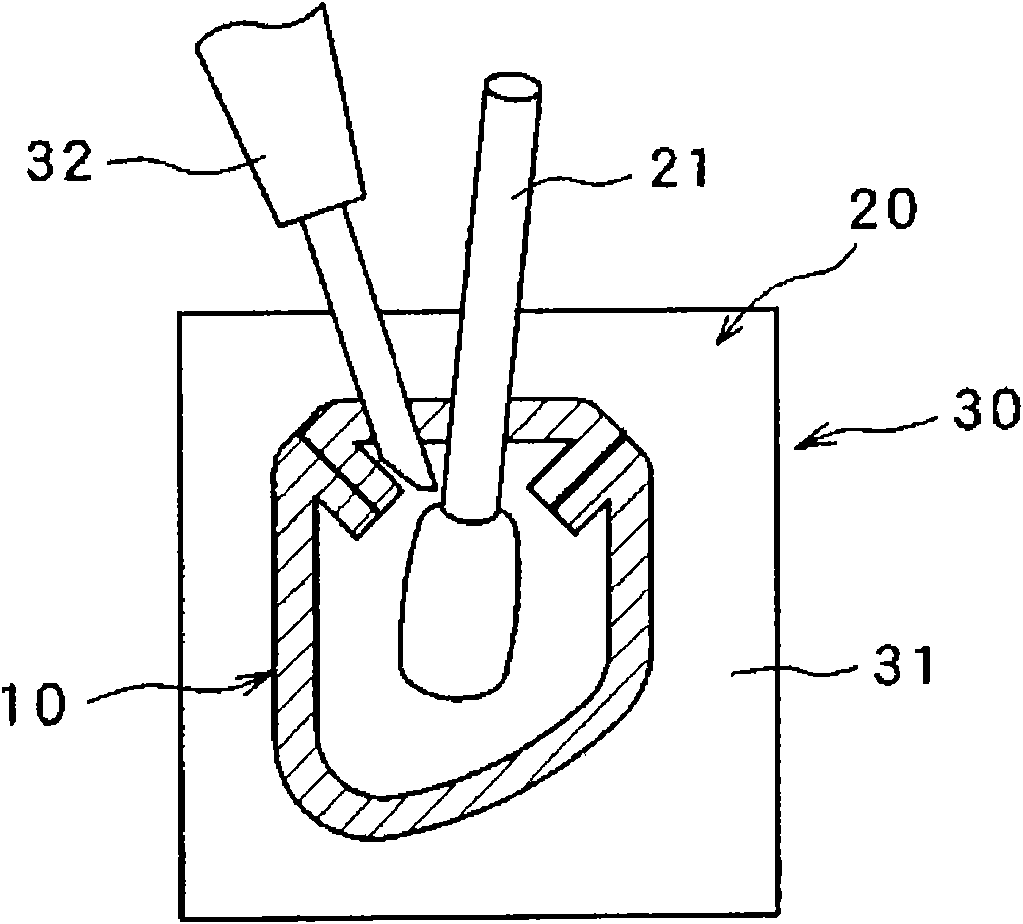

[0078] Into the inside of the evaluation sample obtained from this nonwoven fabric, a foaming resin was injected from an injection nozzle to be fo...

Embodiment 2

[0080] (Example 2) Evaluation sample: A nonwoven fabric using a 2-layer laminate having an average weight per unit area of 35 g / m by hot embossing 2 On one side of a styrene-based elastomer resin melt-blown non-woven fabric (SEPS, with an average fiber diameter of 4.5 μm), hot-pressed with an average weight per unit area of 30 g / m 2Polybutylene terephthalate (PBT, average fiber diameter 3.5 μm) is a two-layer laminate of melt-blown nonwoven fabric.

[0081] The measured values of this nonwoven fabric are shown in Table 1, and the air permeability (JIS-L1096) is 6.6 cc / cm 2 / s, water pressure resistance (JIS-L1092) is 620mmH 2 O. The average value of pore size (valve point method based on ASTMF-361-80, automatic pore measuring device for porous materials, Perm Porometer POROUSMATERIALS, INC.) is 8.6 μm.

[0082] Into the evaluation sample obtained from this nonwoven fabric, a foamed resin was injected from an injection nozzle to be foamed and cured, thereby obtaining a ...

Embodiment 3

[0084] (embodiment 3) evaluation sample: using the average weight per unit area is 70g / m 2 A single layer of polypropylene resin melt-blown non-woven fabric (PP, average fiber diameter 3.0 μm).

[0085] The measured values of this nonwoven fabric are shown in Table 1, and the air permeability (JIS-L1096) is 11.7 cc / cm 2 / s, water pressure resistance (JIS-L1092) is 918mmH 2 O. The average value of pore size (valve point method based on ASTMF-361-80, automatic pore measuring device for porous materials, Perm Porometer POROUS MATERIALS, INC.) is 10.4 μm.

[0086] Into the inside of the evaluation sample obtained from this nonwoven fabric, a foaming resin was injected from an injection nozzle to be foamed and cured, thereby producing a foam molded article integrated with the evaluation sample.

[0087] The average value of the surface hardness (JIS K6400-2) of the obtained foam molding was 43N, and the change in surface hardness was less than 10N. Nests caused by air bubbles....

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com