A process for the preparation of primary alkyl glycerol ethers useful as biofuel additive from glycerol

A technology for primary alkyl glycerol and glycerol ether, which is applied in the field of preparing glycerol ether and can solve problems such as structural instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

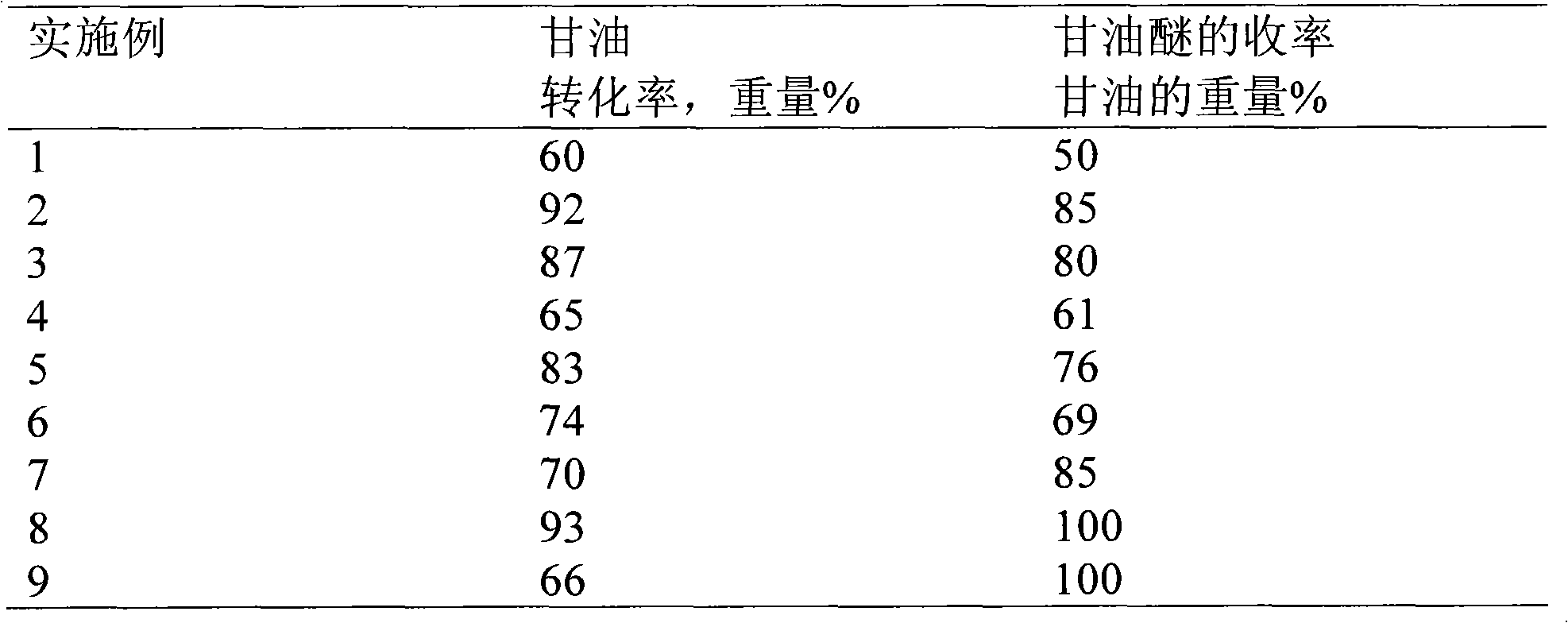

Examples

Embodiment 1

[0028] This example illustrates the preparation of glyceryl ethyl ether over a gamma alumina catalyst. In a typical preparation, a 5:1 molar ratio of ethanol and glycerol with a gamma-alumina catalyst (5 wt% of the total reaction mixture) was heated at 100°C for 5 hours in a closed autoclave. Solid acid catalyst - gamma alumina was obtained from commercial sources. The solid catalyst was pretreated at 500°C and activated by procedures recommended by catalyst manufacturers and well known to those skilled in the art prior to use in etherification reactions. At the end of 5 hours, the solid catalyst was removed and the glycerol ether was separated from unreacted glycerol, water and alcohol by a combination of extraction (with water) and distillation procedures. The product was analyzed by gas chromatography.

Embodiment 2

[0030] This example is illustrated on a zeolite beta catalyst (silica / alumina = 40; surface area = 550 m 2 / g; size = 0.1-0.5 microns) to prepare glyceryl ethyl ether. In a typical preparation, ethanol and glycerol in a molar ratio of 5:1 were heated with zeolite beta (5 wt% of the total reaction mixture) at 100°C for 5 hours in a closed autoclave. The solid catalyst was pretreated for activation at 450°C. At the end of the reaction, the catalyst was removed and the glycerol ether was separated from unreacted glycerol, water and alcohol by a combination of extraction (with water) and distillation procedures. The product was analyzed by gas chromatography.

Embodiment 3

[0032] This example is illustrated on a zeolite Y catalyst (silica / alumina = 8; surface area = 420 m 2 / g) to prepare glycerol ethyl ether. In a typical preparation, ethanol and glycerol in a molar ratio of 5:1 were heated with zeolite Y (5 wt% of the total reaction mixture) at 100°C for 5 hours in a closed autoclave. The solid catalyst was pretreated for activation at 450°C. At the end of the reaction, the catalyst was removed and the glycerol ether was separated from unreacted glycerol, water and alcohol by a combination of extraction (with water) and distillation procedures. The product was analyzed by gas chromatography.

PUM

| Property | Measurement | Unit |

|---|---|---|

| cloud point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com