Improvements in emission control

A technology of exhaust system and exhaust manifold, applied in engine control, exhaust device, air quality improvement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

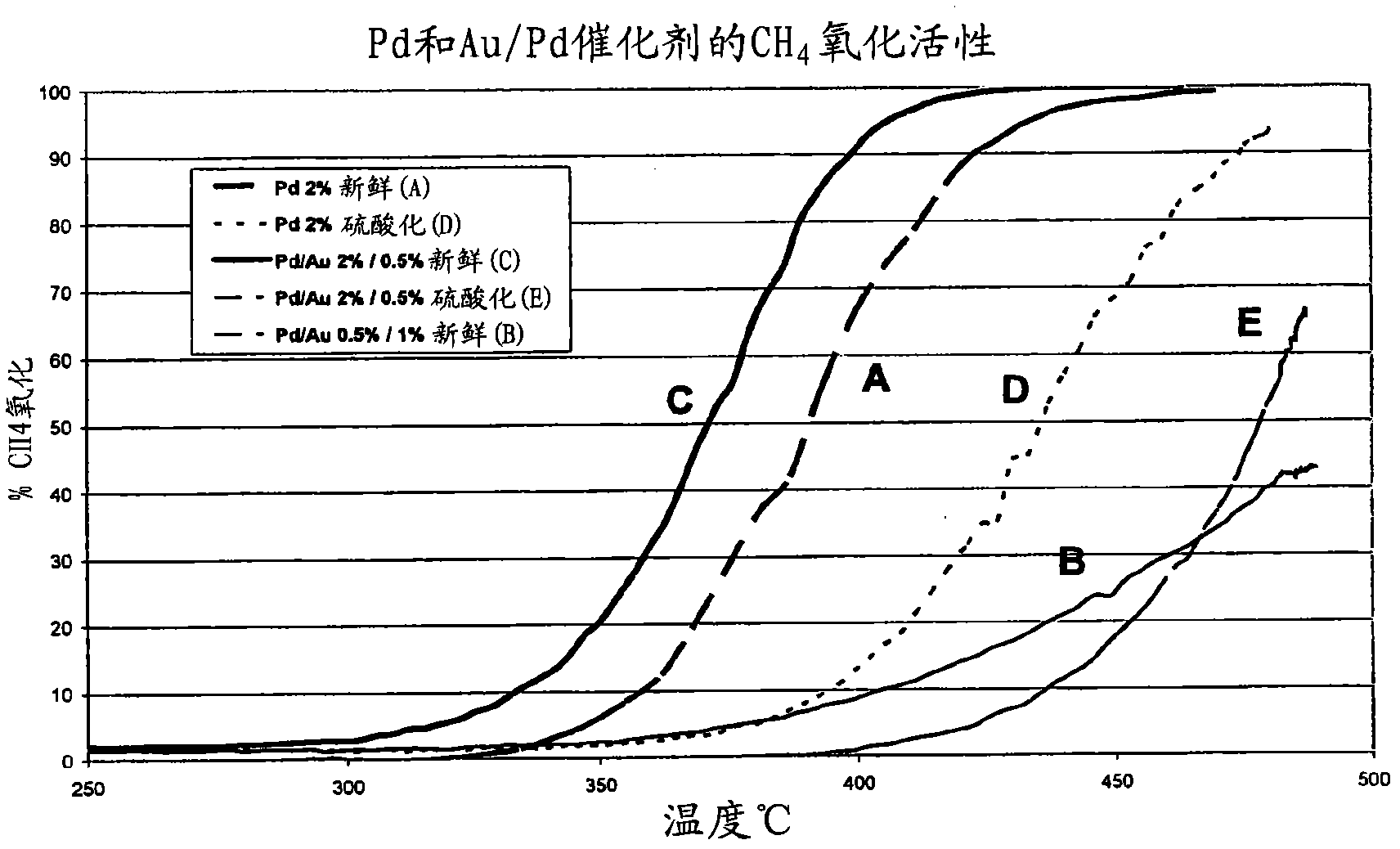

[0033] figure 1 The methane oxidation activity of a range of palladium, gold and palladium / gold catalysts before and after sulfation is shown. The test gases include carbon monoxide (1000ppm), nitrogen oxide (200ppm), sulfur dioxide (2ppm), methane (900ppm), carbon dioxide (4.5%), water vapor (4.5%), oxygen (8%) and the balance of nitrogen. These results confirm the good activity of the palladium catalyst for methane oxidation (curve A, 2% Pd). In contrast, the gold-only catalyst has poor methane oxidation activity (curve B, 0.5% Au). Surprisingly, the addition of gold to the palladium catalyst significantly enhanced the methane oxidation performance (curve C, 2% Pd + 0.5% Au).

[0034] After sulfation, the palladium catalyst showed a clear loss of activity (curve D, 2% Pd), while the catalyst containing palladium and gold showed a greater loss of activity (curve E, 2% Pd + 0.5% Au). Thus unsulfated palladium / gold catalysts have excellent activity, but perform poorly when s...

Embodiment 2

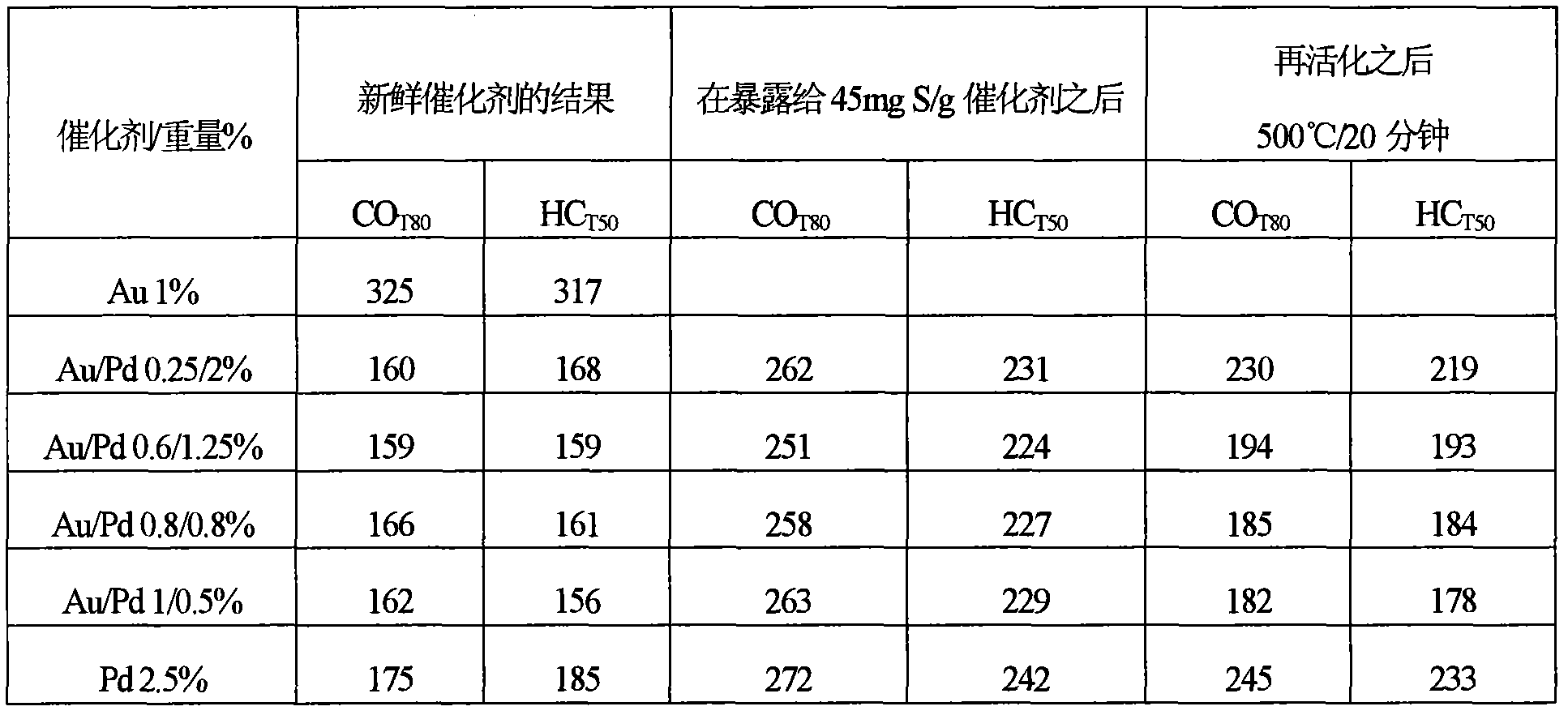

[0036] This example shows that palladium / gold catalysts can be desulfurized and reactivated for oxidation reactions at much lower temperatures than palladium-only catalysts, and this is also the same as that present on engines fueled by natural gas The turbocharger is carried out at a lower temperature than those preceding it, so the desulfurization carried out there is continuously effective, thus maintaining a high catalytic performance. Catalysts were prepared and tested as described above. Test gases include carbon monoxide (1000ppm), nitrogen oxides (200ppm), sulfur dioxide (2ppm), propylene, (900ppm as C 1 ), carbon dioxide (4.5%), water vapor (4.5%), oxygen (12%) and the balance of nitrogen. The test results obtained are given in Table 1 in the form of achieving 80% conversion of carbon monoxide (CO T80 ) and 50% hydrocarbon conversion (HC T50 ) required temperature.

[0037] Table 1. Test results for unsulfated, sulfated and sulfated catalysts after treatment at 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com