Multi-stage electrostatic spraying system and method

An electrostatic spraying and electrostatic droplet technology, applied in the direction of spray discharge device, etc., can solve the problems of poor consistency of droplets, difficulty in obtaining large quantities of droplets, deterioration of droplet consistency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

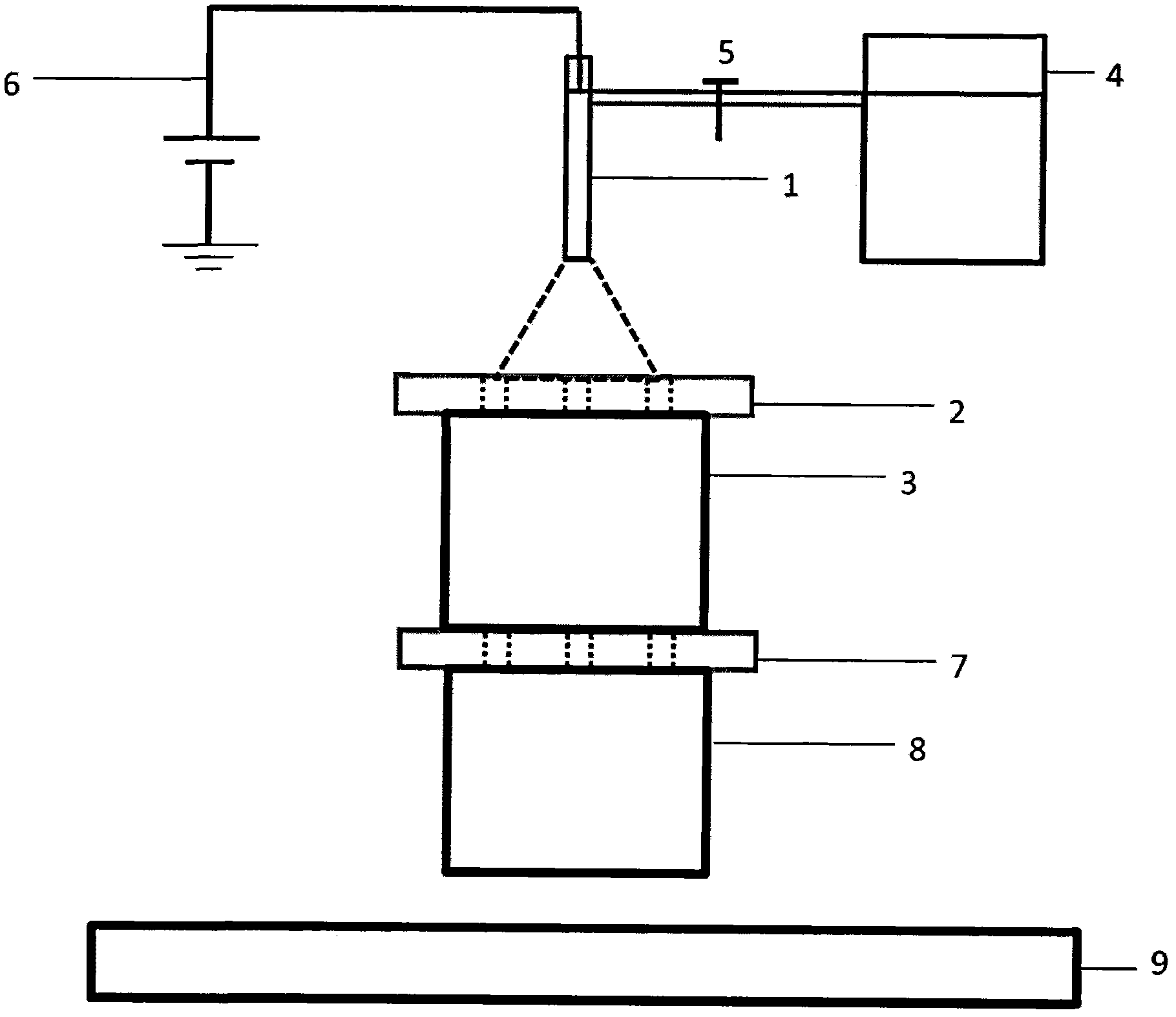

[0037] One of embodiment:

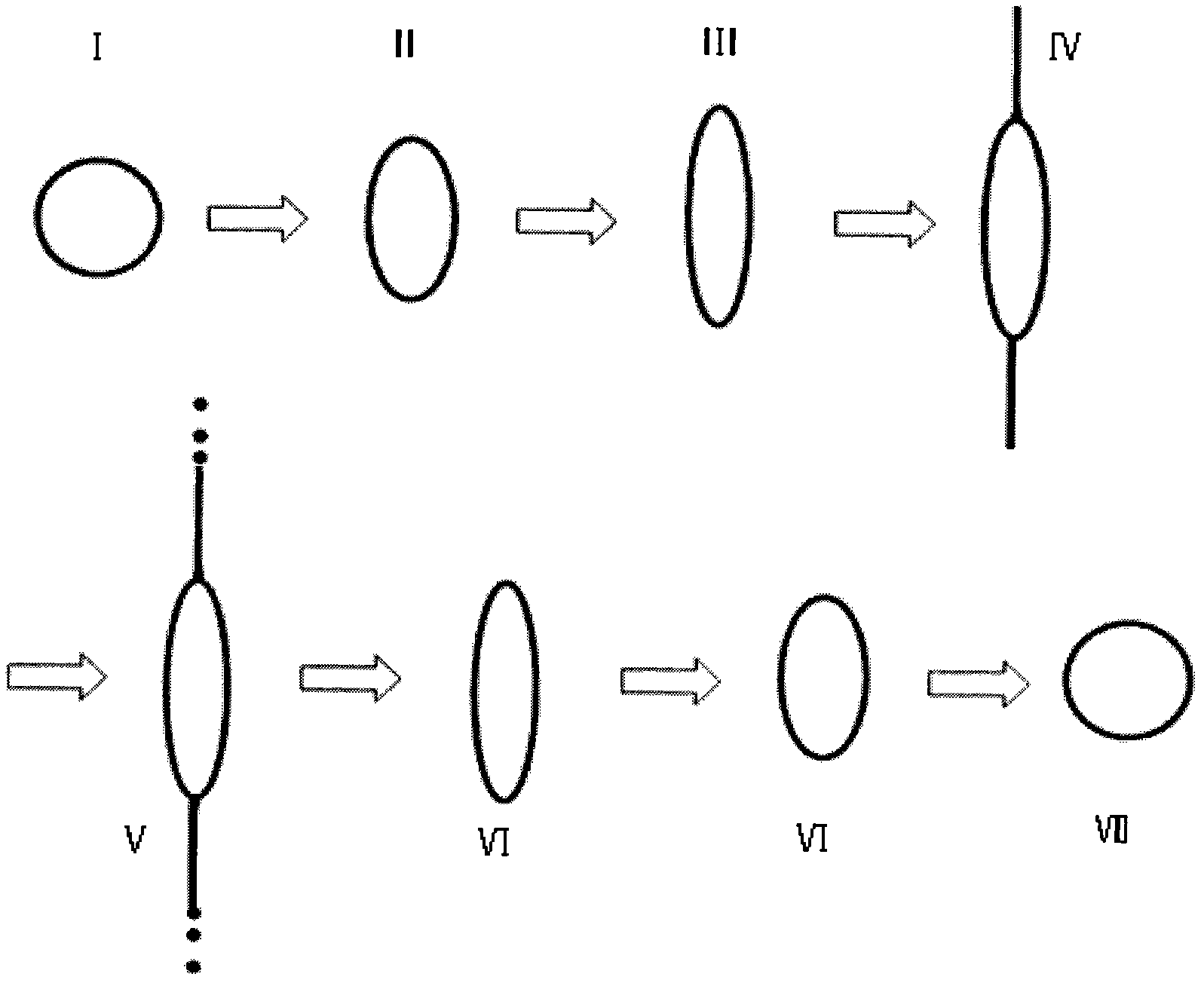

[0038] Single nozzle three-stage electrostatic spraying, Coulomb splitting by preheating, using a mechanical sieve with a specific aperture for droplet screening.

[0039] The second embodiment:

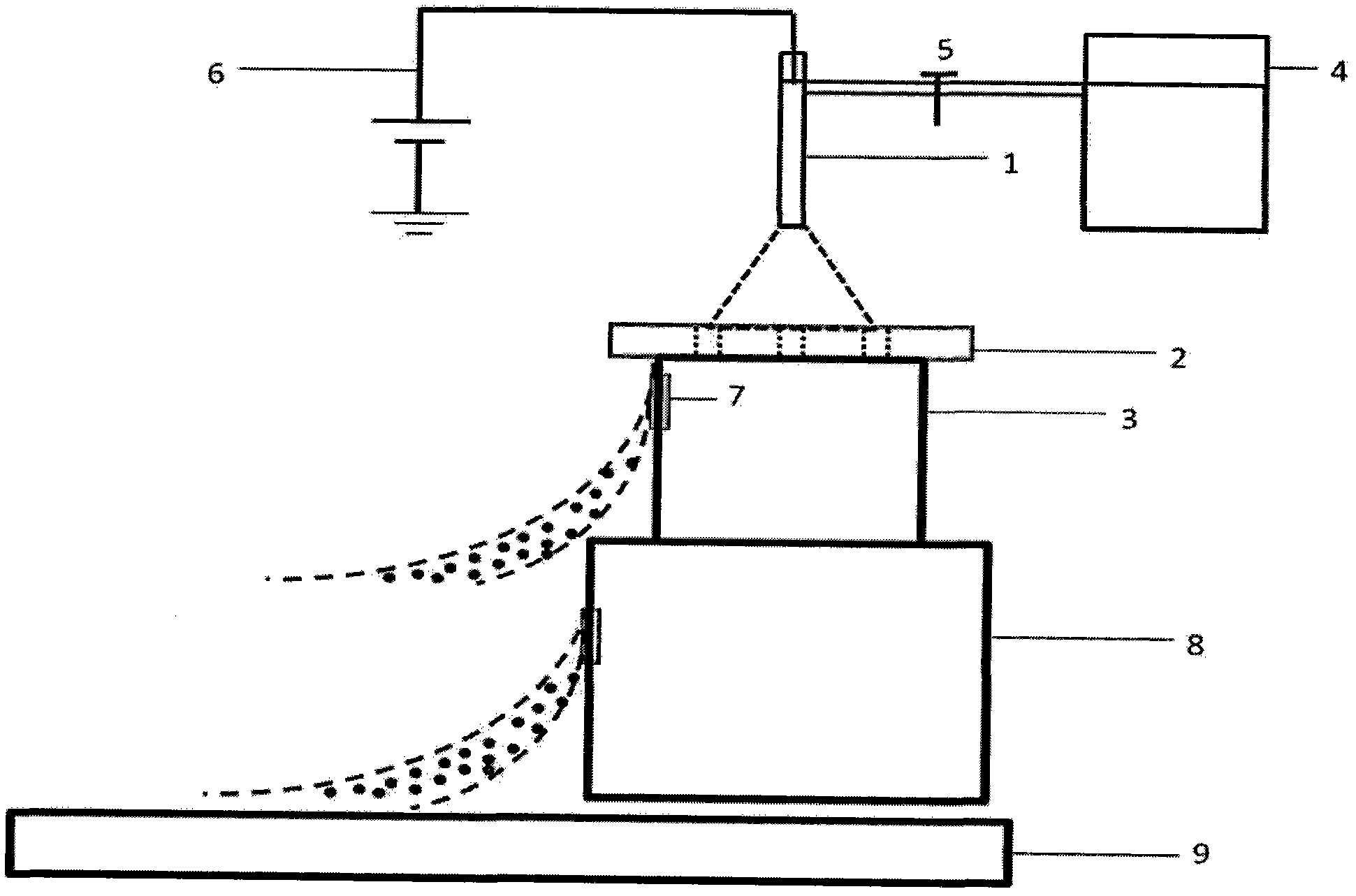

[0040] Single nozzle three-stage electrostatic spraying, change the air pressure to produce Coulomb splitting, use electric field force or magnetic field force to control droplet trajectory (electrostatic field or static magnetic field or alternating electric field or alternating magnetic field) and perform screening.

[0041] The third embodiment:

[0042] Multi-nozzle two-stage electrostatic spraying, the same droplet control device, changes the air pressure or preheating to generate Coulomb splitting principle to form fine droplets, and uses a mechanical sieve with a specific aperture for droplet screening.

[0043] The fourth embodiment:

[0044] Multi-nozzle two-stage electrostatic spraying, multiple droplet control devices, changing air pressure o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com