Fork type blade root milling cutter of turbine blade

A technology of steam turbine blades and fork-shaped blade roots, which is applied in the field of special milling cutters for mechanical cutting, can solve the problems that the manufacturing accuracy of blade grooves is not easy to meet the requirements of drawings, poor processing conditions, scrapping of milling cutters, etc., and achieves easy large-scale use and Promotion and adjustment are quick and easy, and the effect of high cutting positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

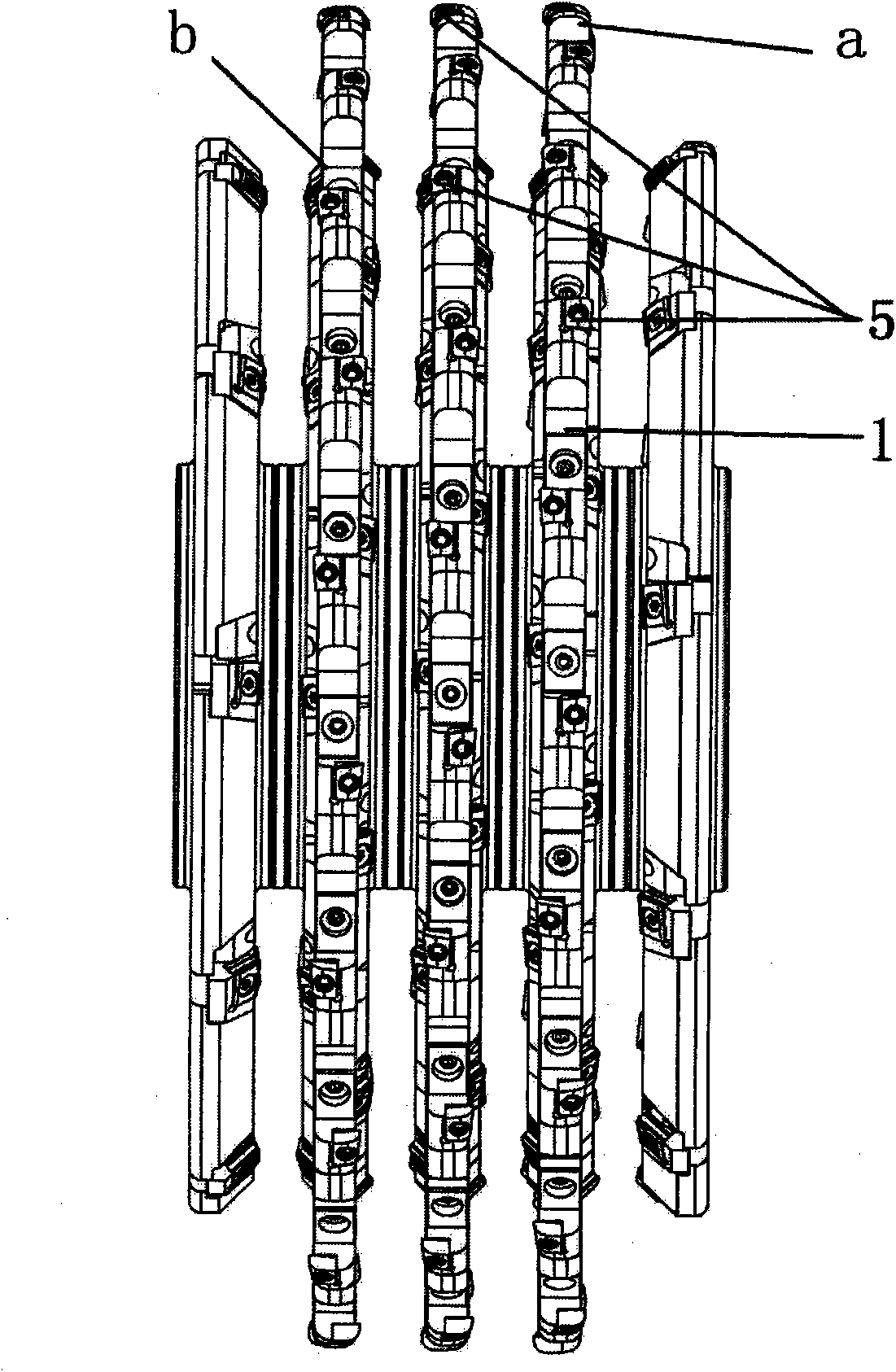

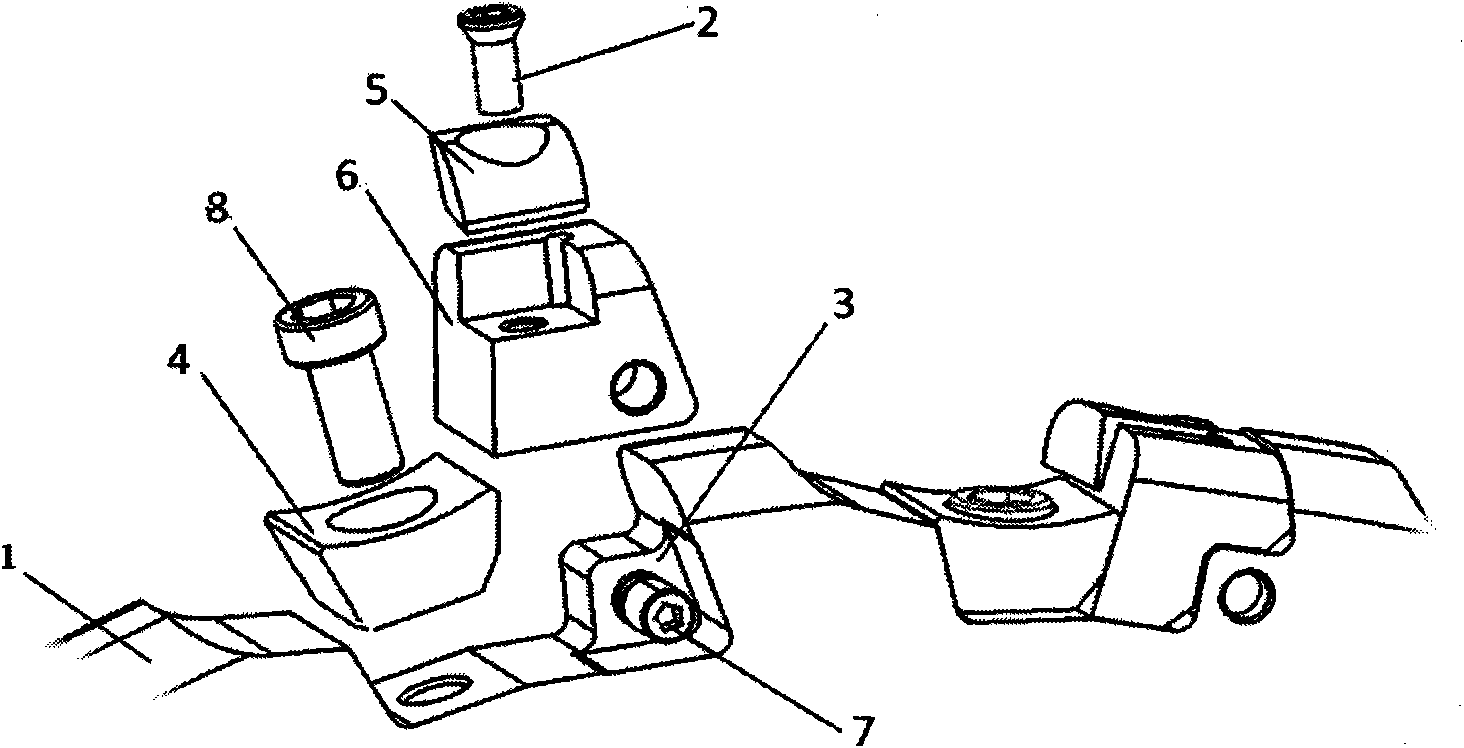

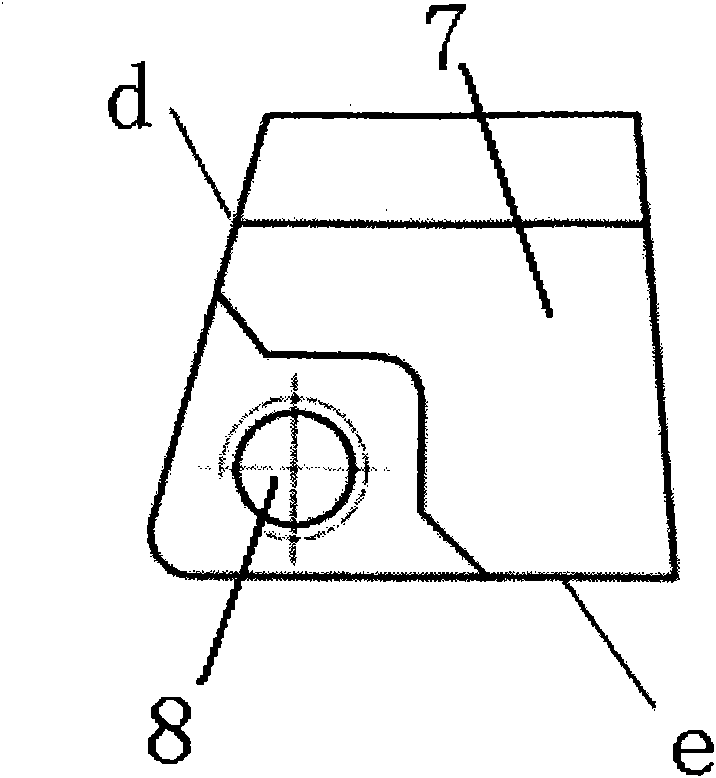

[0018] Such as Figure 1 to Figure 5 As shown: the present invention is a fork-shaped blade root milling cutter for a steam turbine blade, which is a disc-shaped combined milling cutter, which is formed by combining and assembling a plurality of disc-shaped cutter bodies 1 side by side on the milling cutter shaft. The cross-sectional shape of the disc-shaped cutter body 1 of the present invention has multiple structural forms such as one-step boss, second-step boss, and third-step boss, which is consistent with the processed blade root structure. The cross-sectional shape of the disc-shaped cutter body 1 in this example is a first-order boss structure, and a plurality of blades 5 and knife seats 6 thereof are respectively provided at the outer edge a and the first-order convex shoulder b of the disc-shaped cutter body 1, respectively. The outer edge a of the disc-shaped cutter body 1 and the first-order shoulder b are evenly distributed in the circumferential direction. The b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com