Technology for preparing tetrafluoroethylene through dilution and pyrolysis of difluorochloromethane and water vapor

A difluorochloromethane, dilute cracking technology, applied in the preparation of halogenated hydrocarbons, chemical instruments and methods, organic chemistry, etc., can solve problems such as pollution, and achieve the effect of solving environmental pollution problems, simple preparation, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

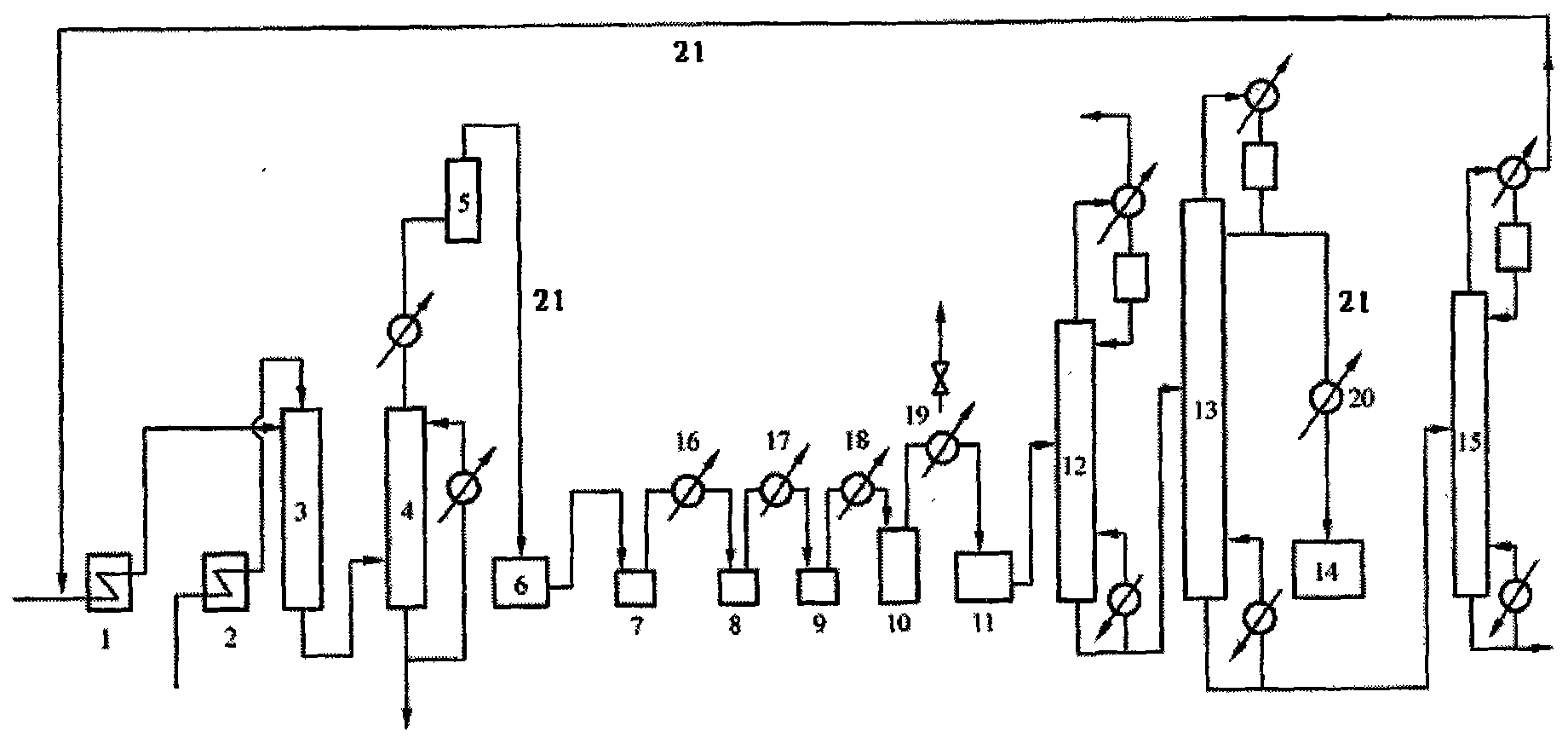

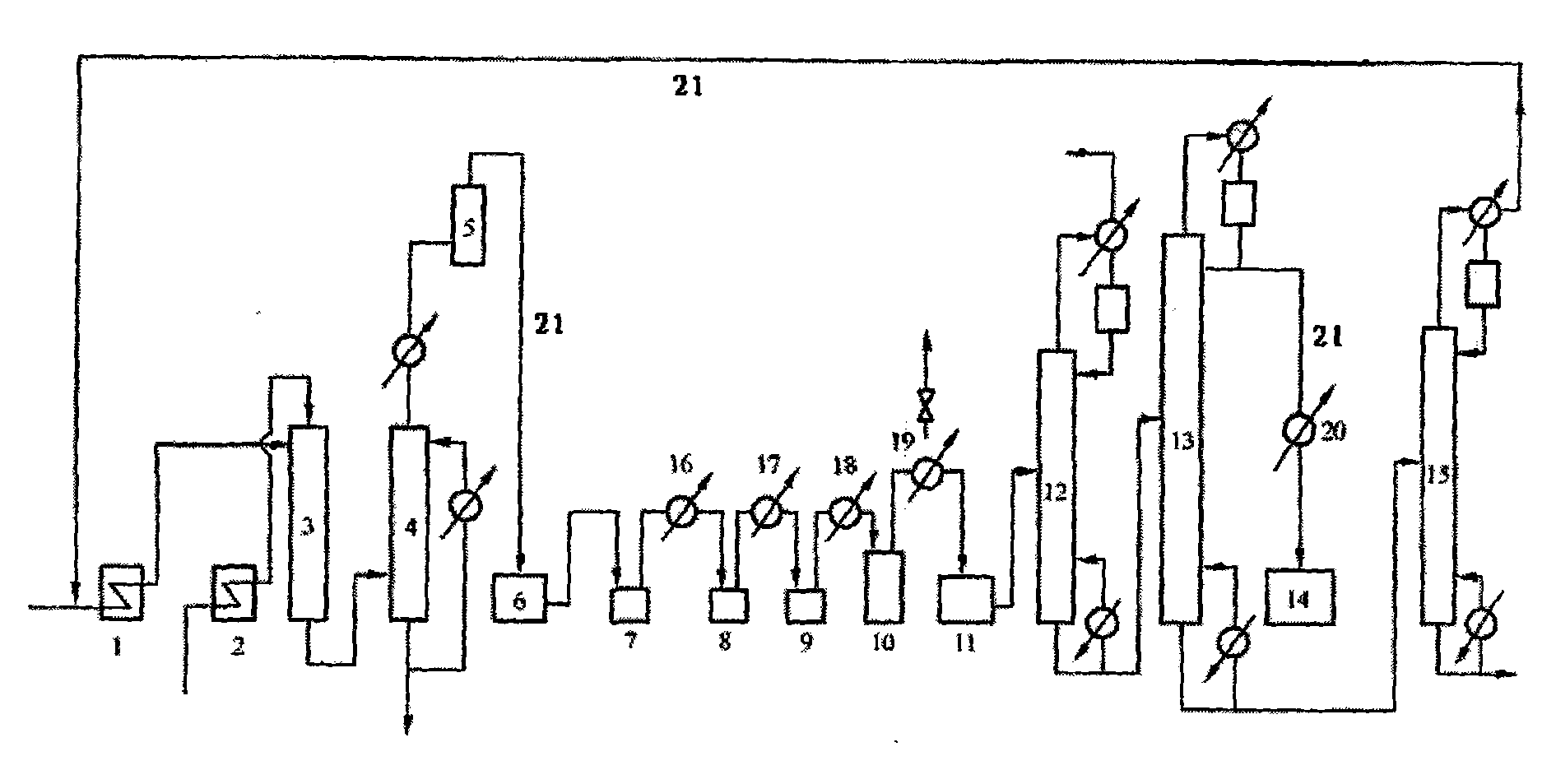

[0010] refer to figure 1 , Difluorochloromethane preheater 1, steam preheater 2, reactor 3, quench cooler 4, graphite condenser 5, concentrated sulfuric acid dryer 6, left compressor 7, left cooler 16, middle compressor 8. Intermediate cooler 17, right compressor 9, right cooler 18, deaerator 10, left condenser 19, storage tank 11, dehydrogenation tower 12, rectification tower 13, right condenser 20, monomer storage tank 14. The difluorochloromethane recovery tower 15 is sequentially connected through the connecting pipeline 21, and is composed of an integrated assembly. When using the technology of the present invention, according to the operating procedures, chlorodifluoromethane is added to the chlorodifluoromethane preheater 1 of the technology of the present invention, and water vapor is added to the steam preheater 2 of the technology of the present invention. Heating to a certain temperature, the mixture of difluorochloromethane and water vapor enters the reactor 3 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com