Gas extraction drilling coupling device and installation and use method thereof

A technology of gas drainage and joint pipe, which is applied in the direction of gas discharge, safety devices, mining equipment, etc., and can solve the problems of slow pipe joint speed, non-recyclable, poor corrosion resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

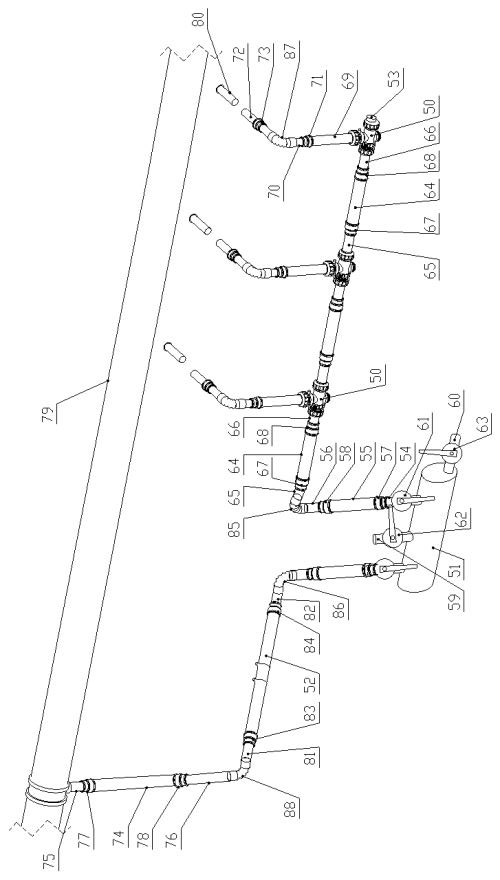

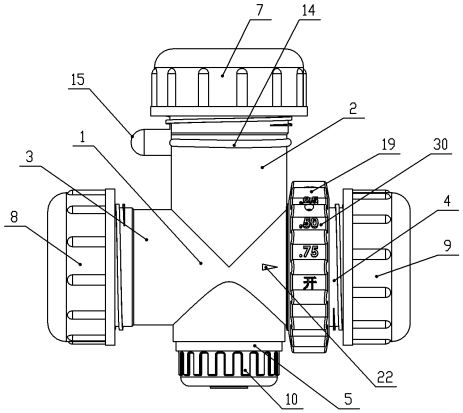

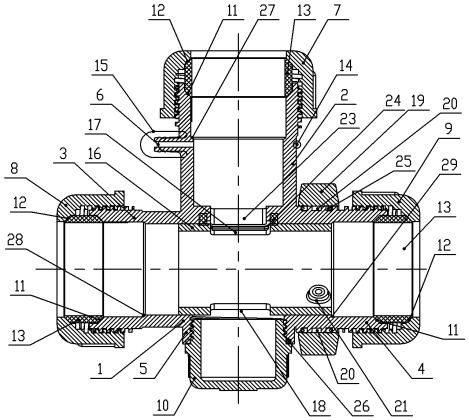

[0062] Such as Figure 1 to Figure 9 As shown, the gas drainage drilling pipe coupling device of the present invention includes a sealing pipe connecting pipe fitting, a vertical connecting pipe fitting, a five-way valve 50, a horizontal connecting pipe fitting, a water release device 51, an orifice flow meter 52, and a gas drainage main pipe Connect the pipe fittings, the air outlet of the sealing pipe connecting pipe fittings is sealed and connected with the air inlet of the five-way valve 50 through the vertical connection pipe fittings, the air outlet of the five-way valve 50 is connected with the air inlet of the water release device 51 through the horizontal connection pipe fittings, and the hole The air inlet and the air outlet of the plate flowmeter 52 are respectively sealed and connected with the air outlet of the drainer 51 and the air inlet of the connecting pipe of the gas extraction main pipe.

[0063] There is at least one connecting pipe fitting, vertical conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com