Liquid crystal display panel and manufacturing method thereof

A technology of liquid crystal display panel and manufacturing method, which is applied in the direction of nonlinear optics, instruments, optics, etc., and can solve the problems of liquid crystal outflow, liquid crystal pollution of frame glue, holes in frame glue, etc., so as to save materials and costs, and prevent stretching damage or oily handwriting intrusion, the effect of eliminating pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

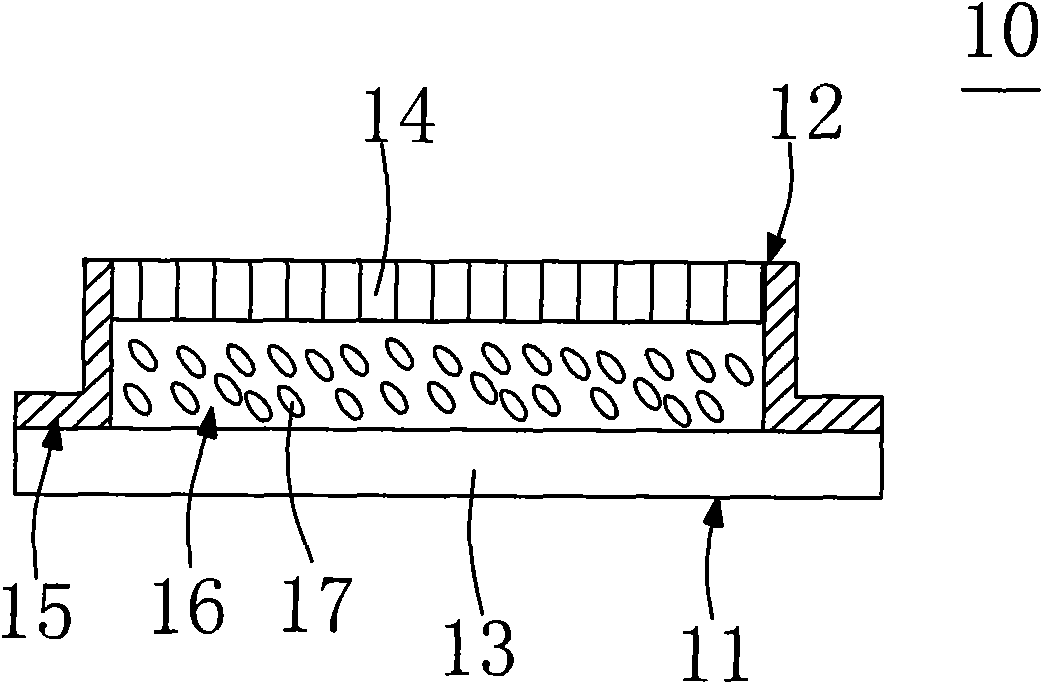

[0025] See image 3 , image 3 Shown is a schematic diagram of a liquid crystal display panel according to the present invention. The present invention provides a liquid crystal display panel 10 . The liquid crystal display panel 10 includes a first substrate 11 , a second substrate 12 and a liquid crystal layer 17 . Wherein, the first substrate 11 is a thin film transistor array substrate, and the second substrate 12 is a color filter substrate. The first substrate 11 has a first insulating substrate 13 , such as a glass substrate; the second substrate 12 has a second insulating substrate 14 made of plastic material. In addition, the first substrate 11 also includes scanning wires, data wires, thin film transistors, and pixel electrodes formed on the first insulating substrate 13 , and the second substrate 12 also includes black wires formed on the second insulating substrate 14 . Matrix, color layer, protective layer, transparent electrode (ITO) conductive film, etc. And...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com