High-precision online measuring instrument and measuring method for strip shape of plate and strip

A measurement method and a technology of plate and strip, applied to length measuring devices, metal processing equipment, metal rolling, etc., can solve problems such as distortion of flatness results, achieve signal processing time reduction, reliable measurement data, and easy manufacturing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings.

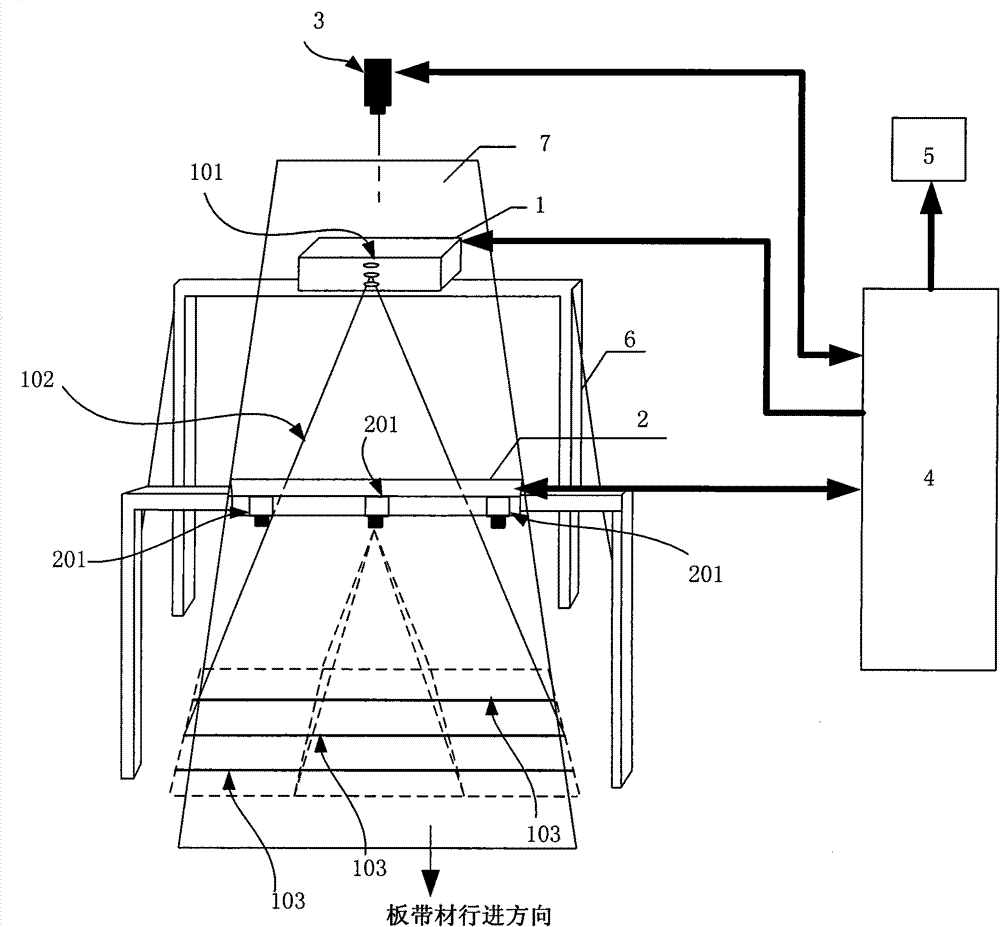

[0026] Such as figure 1 As shown, the high-precision plate and strip shape online measuring instrument provided by the present invention includes a field installation bracket 6 across the plate and strip production line, a light source box 1, a detection box 2, a strip speed measuring instrument 3, and is installed in the operation The measurement control cabinet 4 and the display 5 of the room. The on-site installation bracket 6 straddles the top of the tested board strip 7, and the detection box 2 and the light source box 1 are respectively fixedly installed on the two on-site installation brackets 6, and the height of the light source box 1 must be Lower than the height of the detection box 2, the height of the light source box 1 mainly depends on the design of the angle between the laser line and the surface of the strip 7 of the tested board. A strip s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com