Solar battery, light collection type solar power generating module and solar battery manufacturing method

A technology of solar cells and sunlight, applied in the field of solar cells, can solve problems such as power generation decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

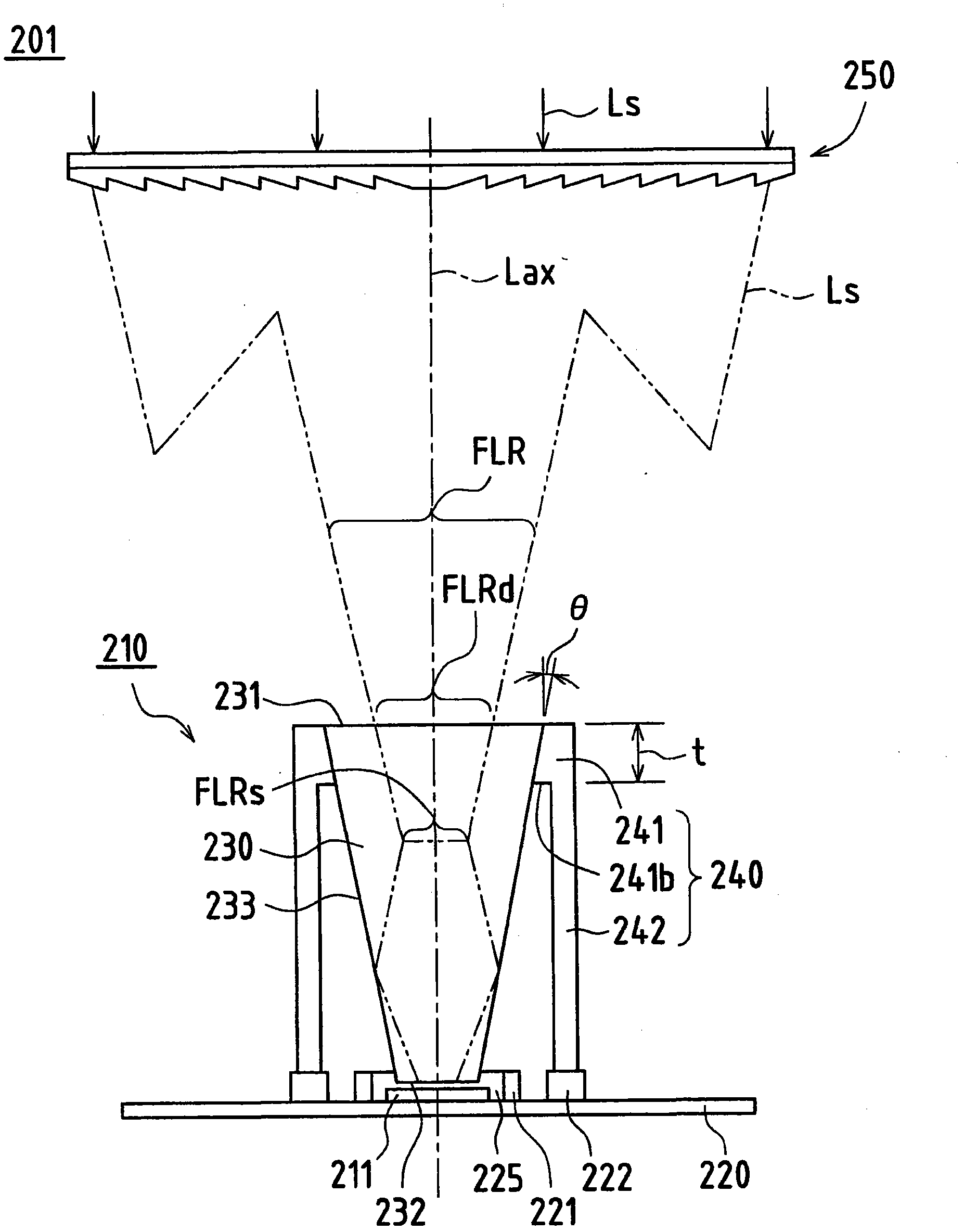

[0129] based on Figure 1A to Figure 3B The solar cell and the concentrating solar power generation module of this embodiment will be described.

[0130] Figure 1A It is a perspective side view showing the schematic structure of the solar cell and the concentrating solar power generation module in the first embodiment of the present invention on the plane including the optical axis.

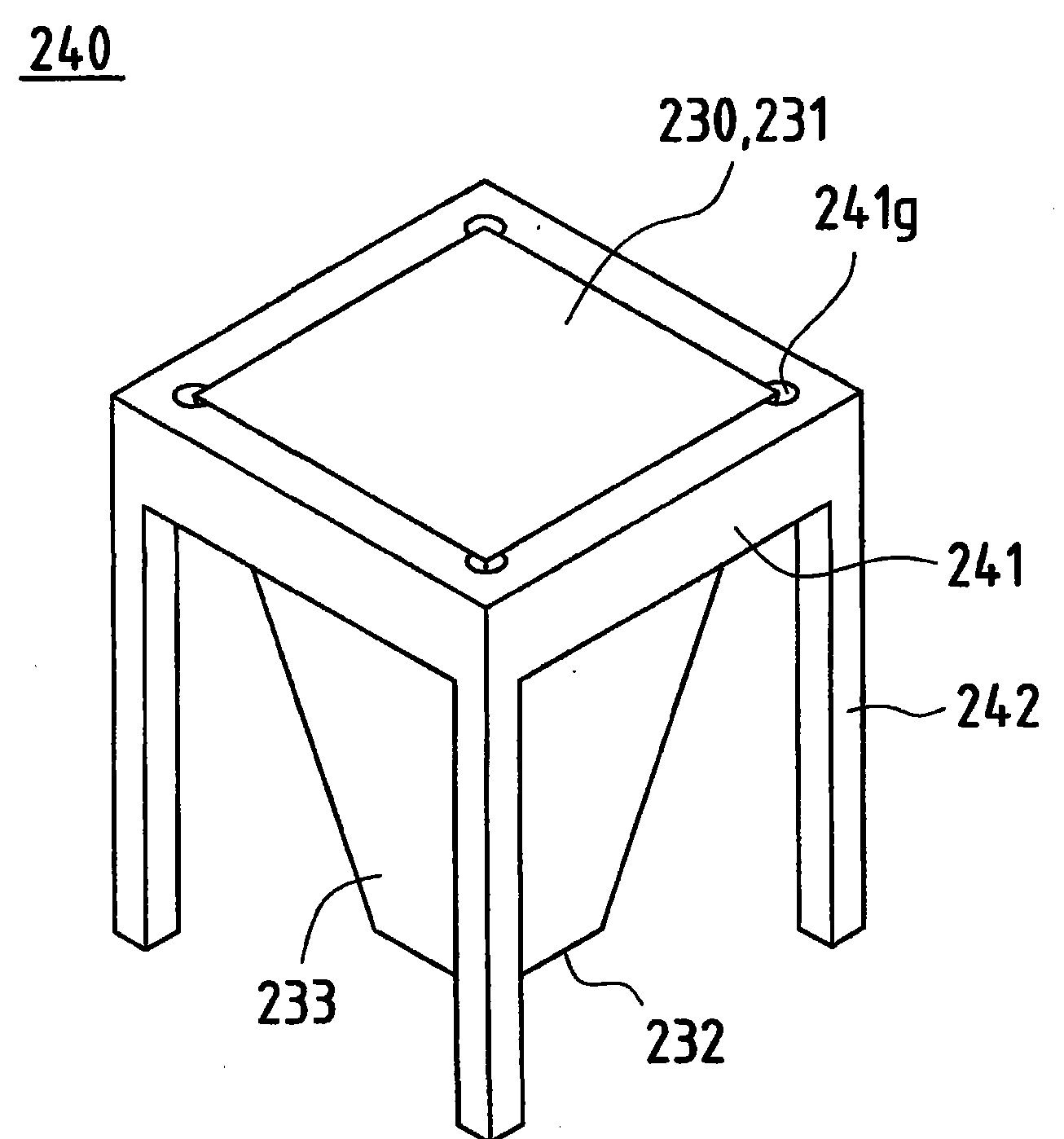

[0131] Figure 1B means viewed from above Figure 1A Perspective view of the appearance of the solar cell holder and cylindrical optical part shown.

[0132] The solar cell 210 of the present embodiment has: a solar cell element 211 for photoelectrically converting the sunlight Ls condensed by the condensing lens 250, a receiving substrate 220 carrying the solar cell element 211, and a device for making the condensed sunlight Ls incident. The incident surface 231 of the solar cell element 211 is disposed opposite to the solar cell element 211 and the columnar optical member 230 is arranged t...

Embodiment 2

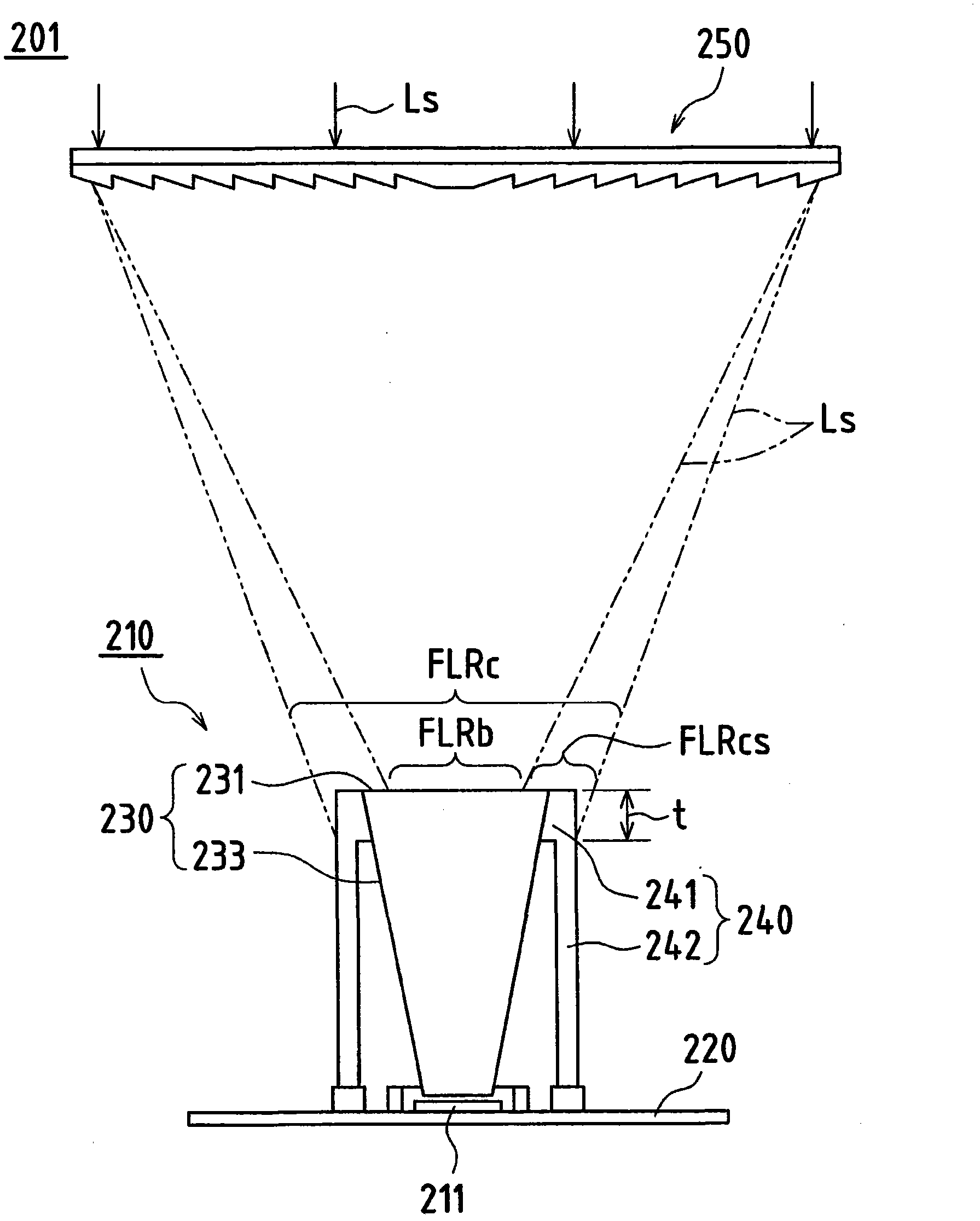

[0154] according to figure 2 The solar cell and the concentrating solar power generation module of this embodiment will be described. The basic structures of the solar cell and the concentrating solar power generation module of this example are the same as those of Example 1. Therefore, the symbols of Example 1 will be appropriately cited and the differences will be mainly described.

[0155] figure 2 It is a side view schematically showing the characteristics of the solar cell and the concentrating photovoltaic module with respect to the wavelength of sunlight according to Example 2 of the present invention.

[0156] The wavelength region of the sunlight Ls includes a short-middle wavelength region from a short wavelength of 400 nm to an intermediate wavelength of 1000 nm (1 μm) and a long-wavelength region exceeding 1 μm. Of the sunlight Ls condensed by the condensing lens 250 , the sunlight Ls in the short-middle wavelength region constitutes the short-middle-wavelength...

Embodiment 3

[0164] according to Figure 3A and Figure 3B The solar cell and the concentrating solar power generation module of this embodiment will be described. The basic structures of the solar cell and the concentrating solar power generation module of this example are the same as those of Example 1 and Example 2. Therefore, the symbols of Examples 1 and 2 will be appropriately cited and the differences will be mainly described.

[0165] Figure 3A It is a side view schematically showing the state of focus shift with respect to the wavelength of sunlight due to the temperature characteristics of the condensing lens in the solar cell and the concentrating solar power generation module according to Example 3 of the present invention.

[0166] Figure 3B is schematically indicated in Figure 3A Top view of the displacement state of the incident surface spotlight area of the incident surface of the solar cell shown.

[0167] The condenser lens 250 of this embodiment is, for example...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com