Fuel cell system

A fuel cell system and fuel cell technology, applied in the direction of fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve problems such as inhalation of air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

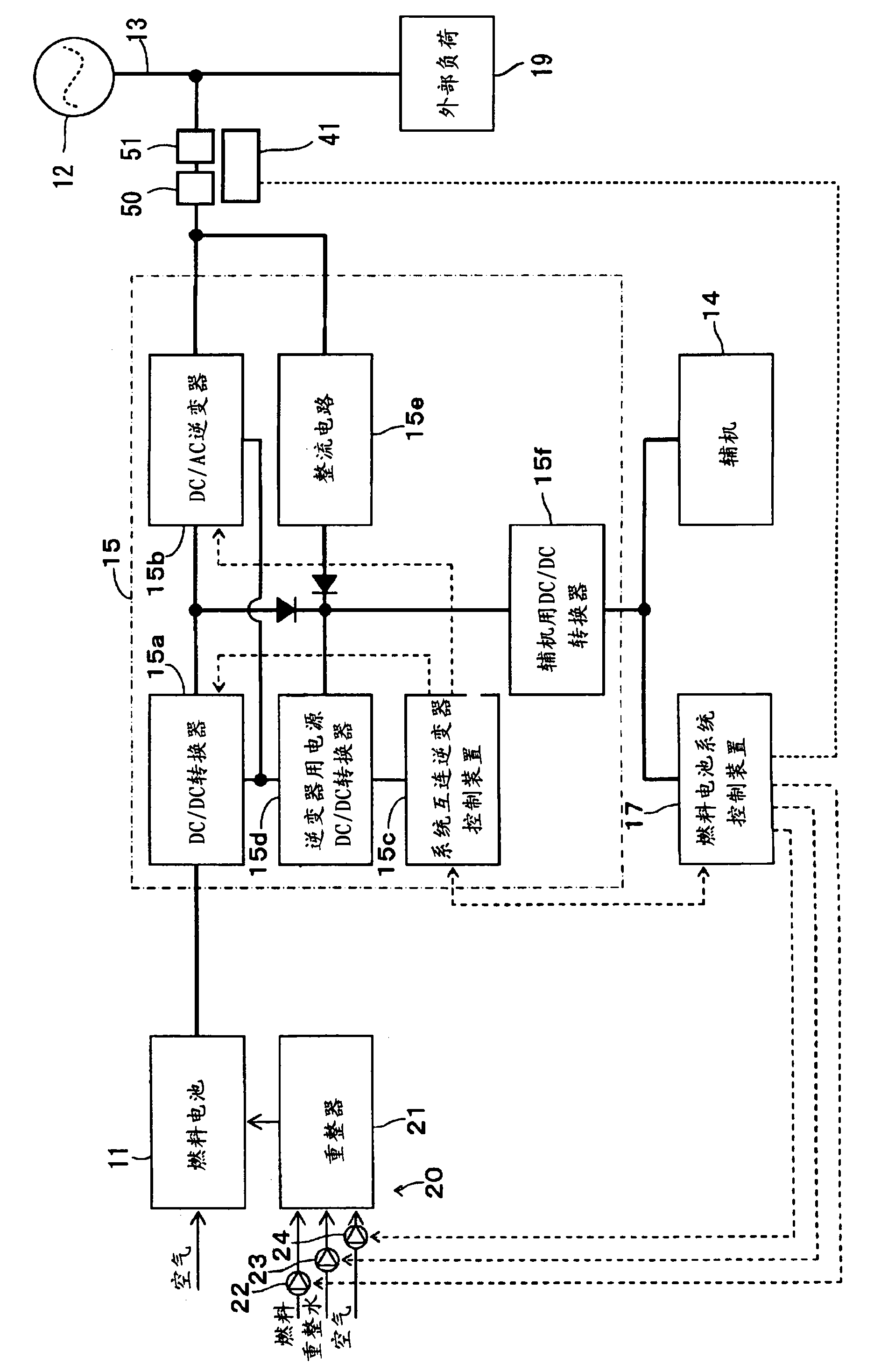

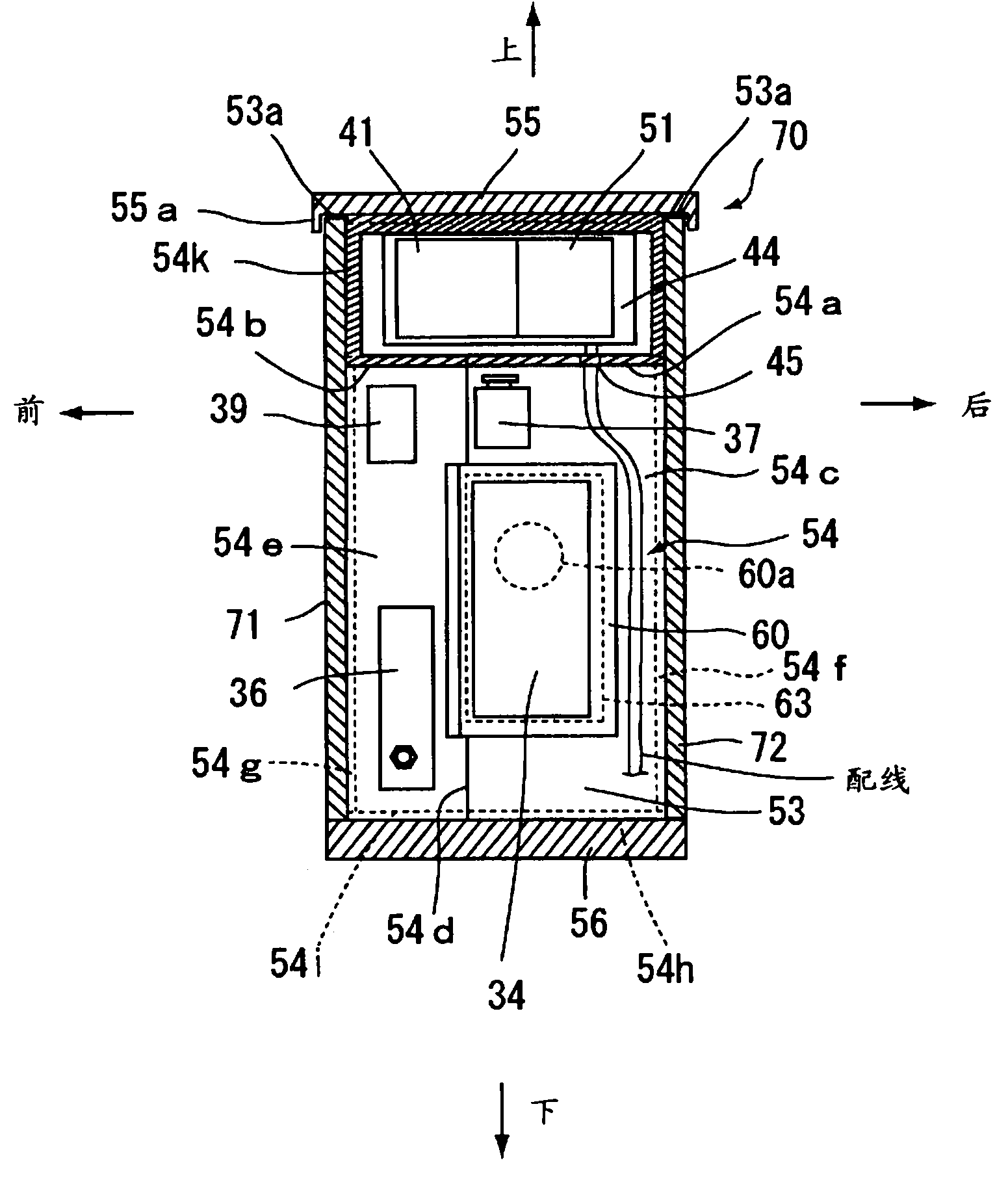

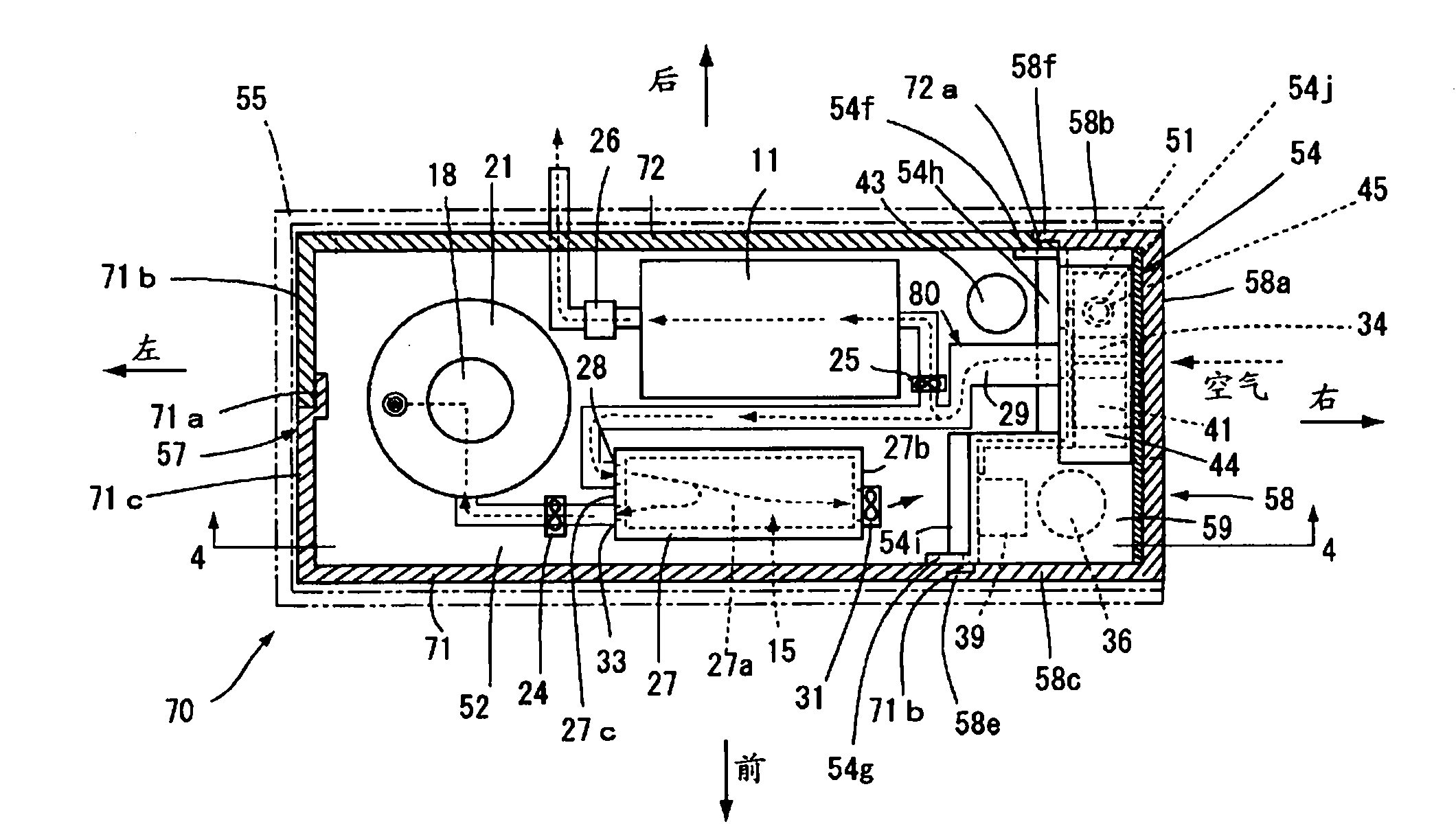

[0021] Next, a first embodiment of the fuel cell system of the present invention will be described with reference to the drawings. figure 1 is a structural block diagram showing the structure of the fuel cell system. This fuel cell system is composed of a fuel cell 11 , a system power supply 12 , a power supply line 13 , auxiliary equipment 14 , an inverter system 15 , a fuel cell system control device 17 , a reformer 21 , a maintenance operation panel 41 , and a circuit breaker 51 . Among them, front, back, left, right, up, down and appended in the text Figure 1 Sincerely.

[0022] The fuel cell 11 is for generating electricity through a chemical reaction of hydrogen and oxygen when supplied with a hydrogen-rich reformed gas and an oxidant gas such as air containing oxygen to output a DC voltage (eg 40V).

[0023] The reformer 21 is used to steam reform the fuel gas and supply the reformed gas rich in hydrogen to the fuel cell 11. Part (hereinafter referred to as CO conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com