Preparation method of integrated BASE component

A technology of alumina and components, applied in the field of preparation of β″ alumina components, to achieve good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

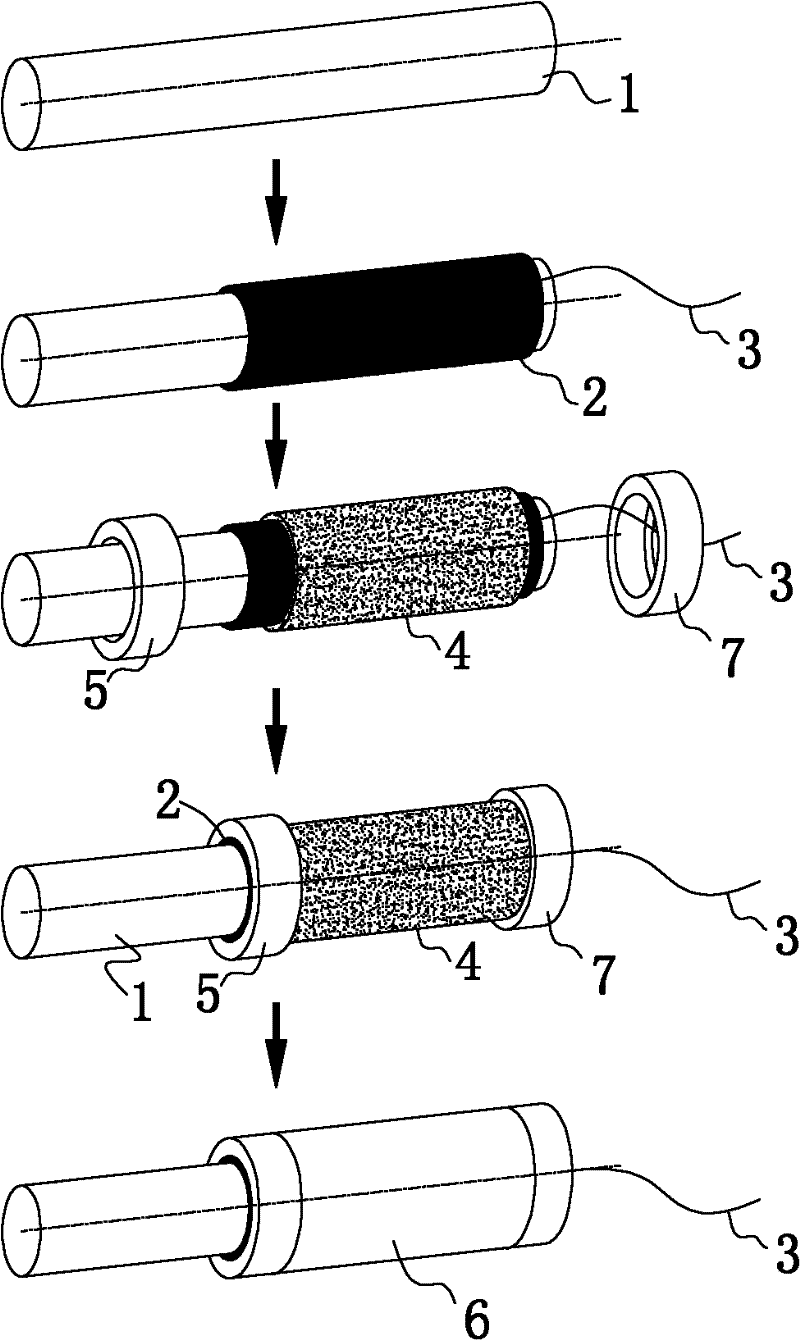

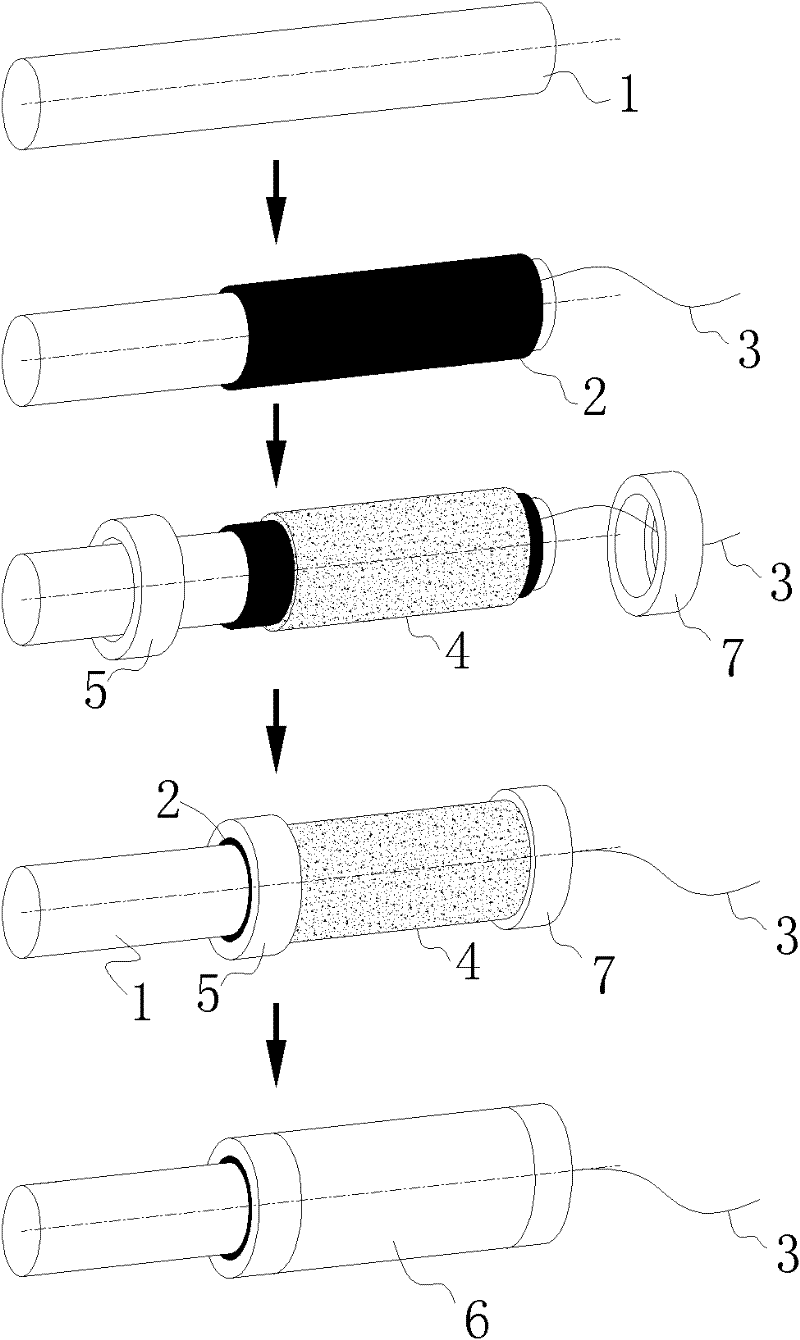

[0023] A method for preparing an integrated β "alumina component, comprising the following steps:

[0024] 1] Wrap the carbon fiber paper 2 on the rod-shaped mold 1 with a smoothness of less than 0.8, and fix the two ends of the carbon fiber paper on the mold; the material of the mold can be graphite, ceramics or refractory metals and their alloys.

[0025] 2] Fix a wire 3 on the carbon fiber paper 2; the wire material can be Mo, Zr, Nb, Hf, Ti, V, Cr, W, Ta, Ru, Rh, Pd, Ag, Os, Ir, Pt, Au or its alloys.

[0026] 3] On the carbon fiber paper 2 fixed with wires in step 2], use a plasma spraying process to spray an electrode material resistant to high temperature and alkali metal corrosion to obtain a porous thin film electrode 4; the electrode material can be Mo, TiN, RhW, TiC, NbN or NbC.

[0027] 4) Connect the insulating sleeve sleeve 5 and the insulating end cap 7 to both ends of the prepared electrode 4 respectively;

[0028] 5] The electrode 4 connected with the insula...

Embodiment 1

[0030] Embodiment 1: Wrap carbon fiber paper 2 with a thickness of 0.15-0.35 mm on a graphite rod with a diameter of 5.5 mm, and fix the carbon fiber paper 2 at both ends of the graphite rod. A molybdenum wire is placed on one end of the carbon fiber paper 2 as a wire 3, and the TiC powder is sprayed on the carbon fiber paper 2 with the molybdenum wire by using a plasma spraying process to obtain a TiC electrode with a thickness of 4.5 μm and a porosity of 36%. layer, which constitutes the electrode 4. an α-Al 2 o 3 The insulating sleeve 5 is butted with one end of the electrode 4, and the molybdenum wire is passed through the α-Al 2 o 3 Connect the wire hole 8 of the insulating end cap 7 to the other end of the electrode 4, and then spray Na-β″-Al on the TiC electrode layer 2 o 3 Powder made of dense Na-β″-Al with a thickness of 0.40mm 2 o 3 layer. At the same time, due to the high temperature of the plasma, Na-β″-Al 2 o 3 Layer 6 and α-Al 2 o 3 Insulating sleeve ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com