Rectangular coordinate five-freedom welding manipulator

A technology of welding manipulator and Cartesian coordinates, which is applied in the field of manipulators, can solve the problems of no rotating mechanism and welding dead corners, which cannot be welded, and achieve the effects of short manufacturing cycle, wide welding area and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

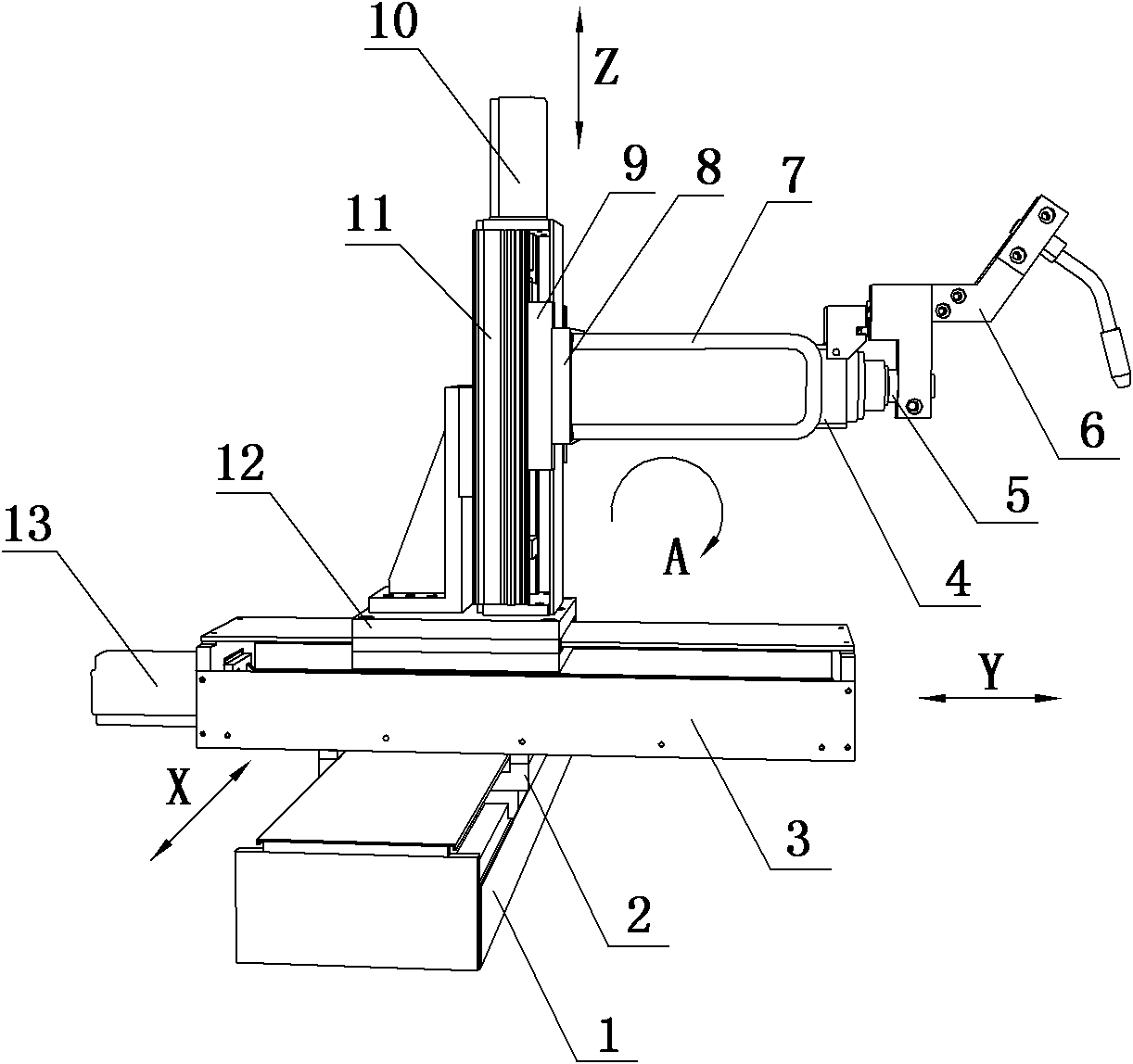

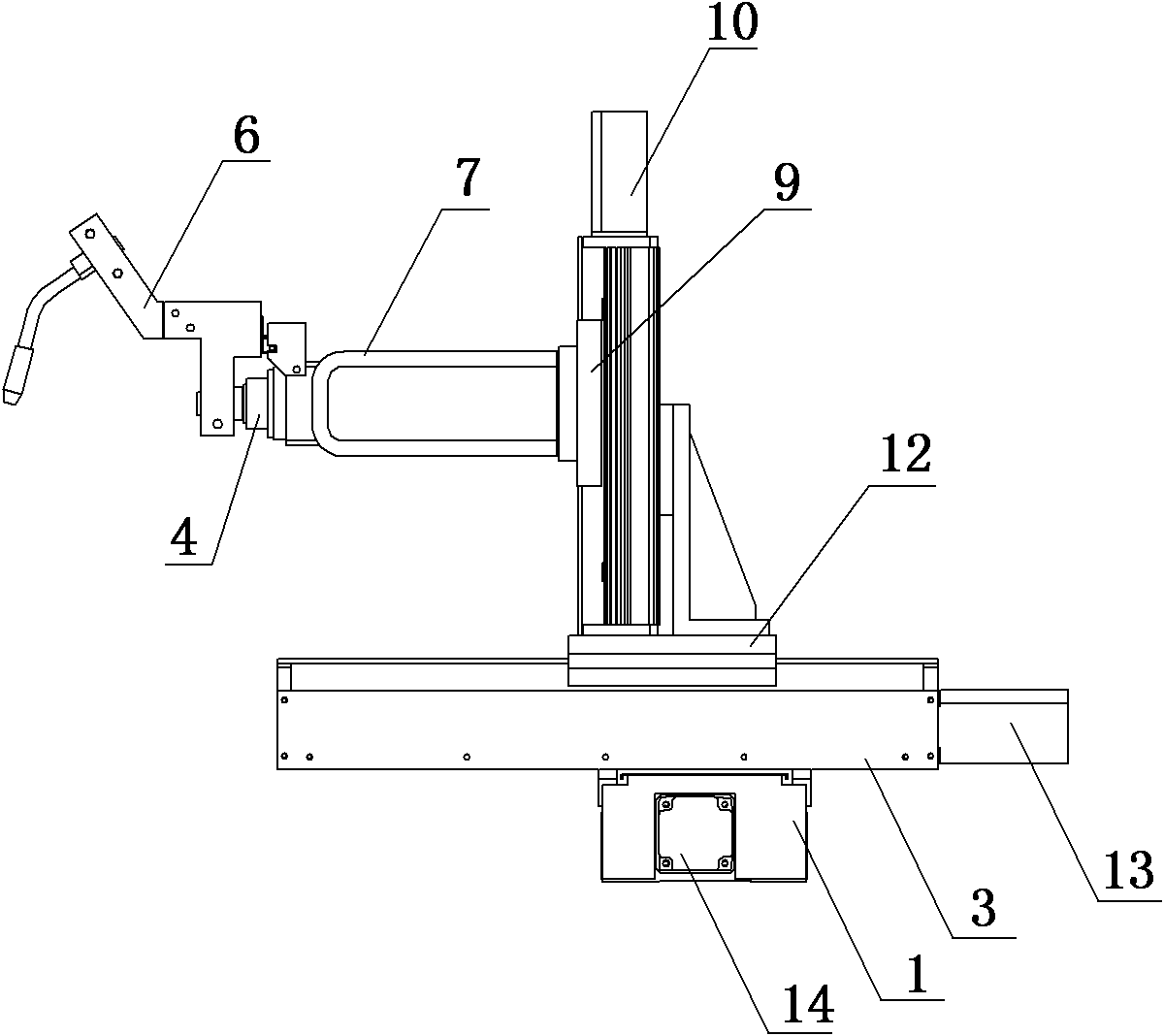

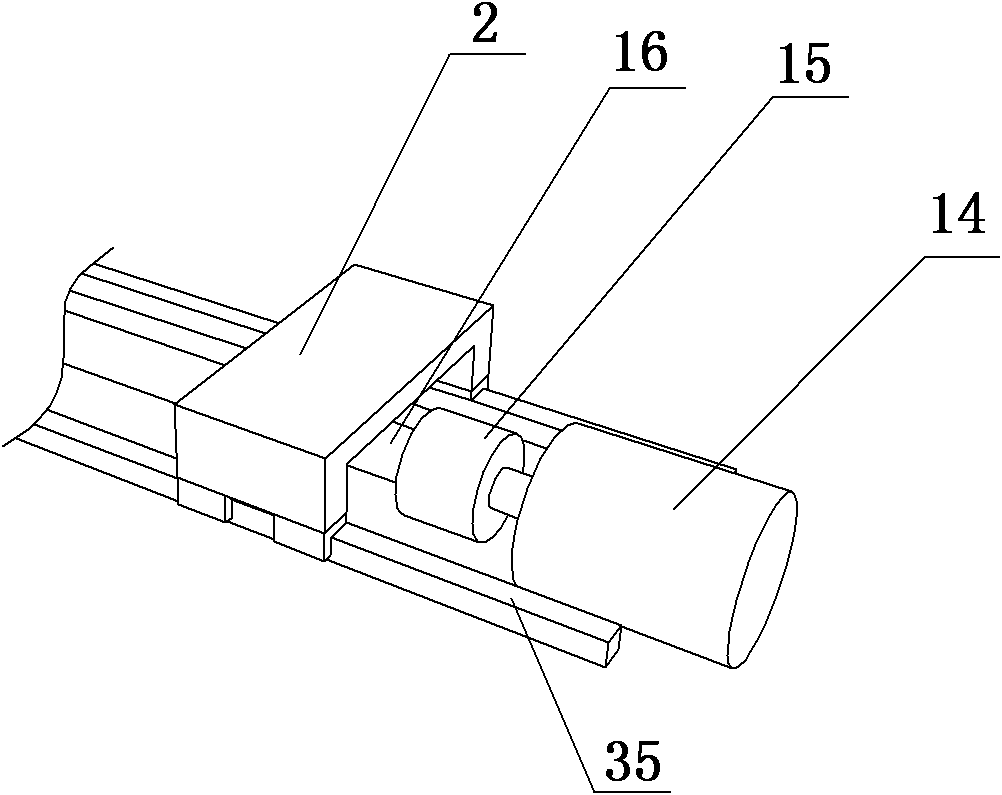

[0027] Such as figure 1 , figure 2 As shown, the Cartesian coordinate five-degree-of-freedom welding manipulator of the present invention (hereinafter referred to as "welding manipulator"), the welding manipulator includes X-axis slide 1, X-axis slide 2, Y-axis slide 3, Y-axis slide 12, Z Axis slider 11 and Z-axis slider 9, X-axis slider 2 can slide along the X-axis slider 1 in the X-axis direction, Y-axis slider 12 can slide along the Y-axis slider 3 in the Y-axis perpendicular to the X-axis direction The Z-axis slide block 9 can slide along the Z-axis slide table 11 in the Z-axis direction perpendicular to the X-axis direction and the Y-axis direction respectively, the Y-axis slide table 3 is connected with the X-axis slide block 2, and the Z-axis slide table 11 is connected with Y-axis slide block 12. The X axis is figure 1 In the direction pointed by the X arrow, the Y axis is figure 1 The direction pointed by the Y arrow in the middle, the Z axis direction is figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com