Cable with ratproof function

A function and cable technology, which is applied in the field of outdoor optical cables, can solve the problems of optical cable bending performance, non-commitment to anti-rat indicators, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

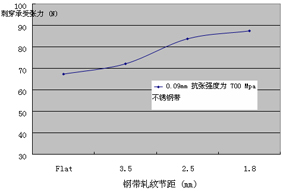

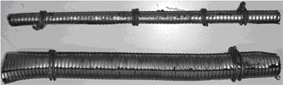

[0034] Figure 4 The structure diagram of a cable with anti-rat function according to the present invention is taken as an example of an optical cable. On the outer side of the waterproof inner sheath 4 of the cable core 1, a layer of corrugated stainless steel strip 2 is longitudinally wrapped. The wall thickness of the steel strip 2 is 0.125mm, the tensile strength of the steel strip is 700MPa, and the corrugation height is 0.45mm. The distance is 1.8mm, and the piercing tension needs to reach 88N after being tested by simulated rat teeth according to the CN101650279A method. Outside the corrugated steel strip 2, a single copper-clad steel wire 3 with a diameter of 0.4 mm is wrapped (that is, the white stripe in the figure), and the distance between adjacent wrapped steel wires 3 is 20 mm. A layer of high-density polyolefin sheathing material 5 with a thickness of 1.8 mm is extruded outside the wrapping steel wire 3 by a conventional extrusion process. Tested by the above ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com