Flexible hinge based clamping and positioning device for linear ultrasonic motor

A technology of linear ultrasonic motor and flexible hinge, which is applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motor, generator/motor, electrical components, etc., which can solve complex assembly, time-consuming processing, and few ultrasonic motors, etc. problems, to achieve the effect of improving vibration characteristics, eliminating mode overlap, and eliminating phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

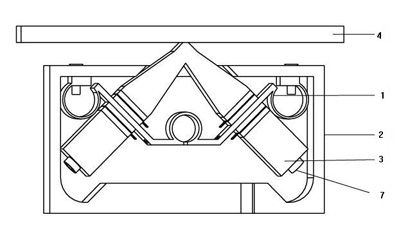

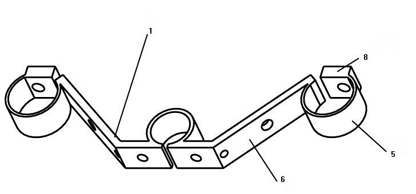

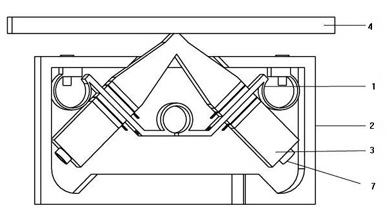

[0018] Such as figure 1 As shown, a clamping and positioning device for a linear ultrasonic motor based on a flexible hinge includes a stator 3 and a mover guide rail 4. There are two vibrators on the stator 3, and the stator 3 has a V-shaped structure. The clamping part 1 is positioned in the open frame 2, and the open frame 2 is provided with an opening on the frame parallel to the mover guide rail 4, and the driving foot of the stator 3 is positioned at the opening of the open frame 2. The clip 1 with a flexible hinge is a U-shaped structure, including flexible arc segments 5 and support arms 6 at both ends and in the middle, and the thickness of the flexible arc segments 5 is much smaller than other parts of the structure, A flexible hinge is formed, and a through hole is opened at the arm tail 8 of the clamping part 1. The clamping part 1 is installed on the opening frame 2 through the through hole, and the supporting arms 6 are respectively perpendicular to the two oscil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com