Deep reactive ion etching method and gas-flow control device thereof

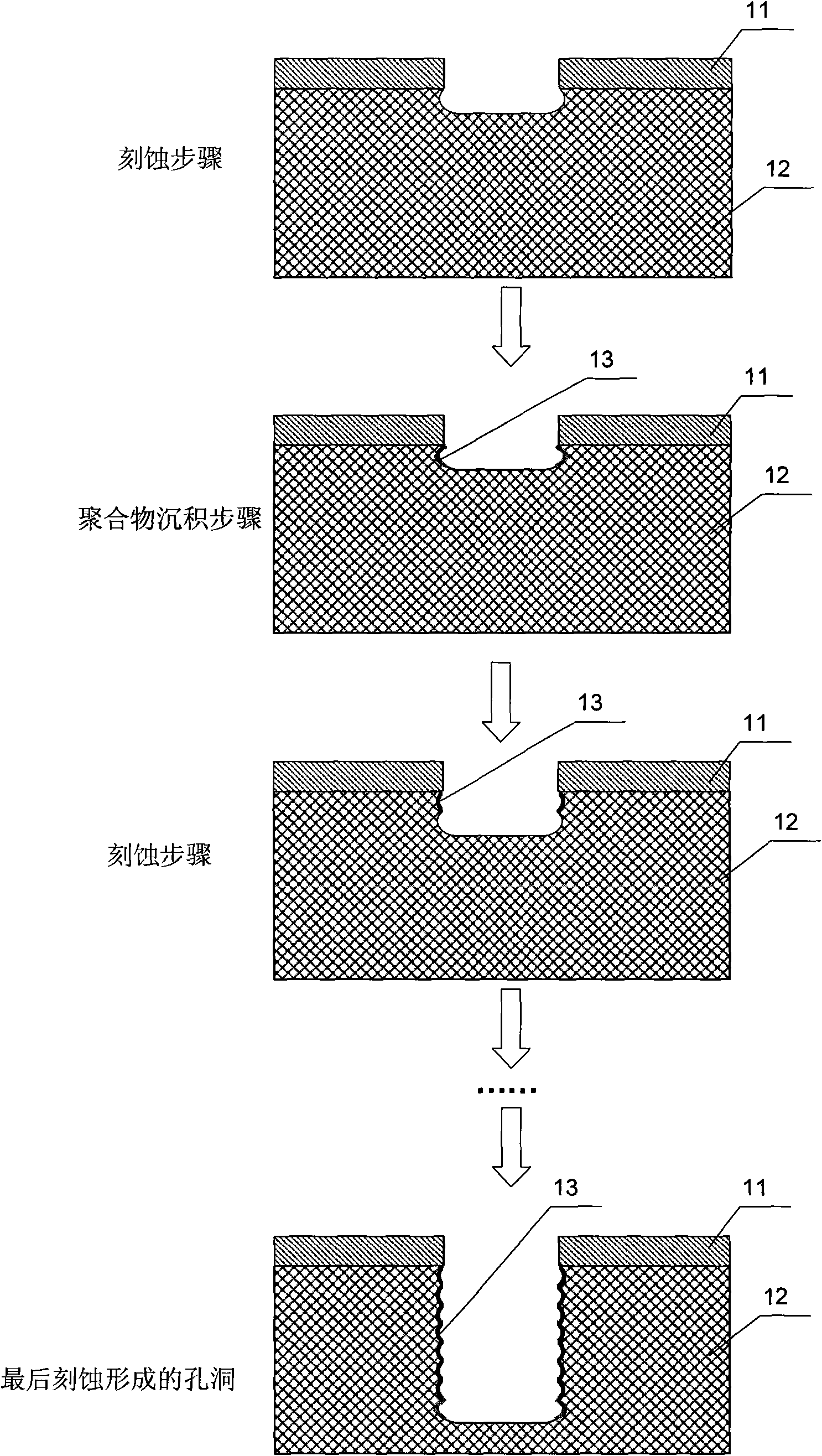

A deep reaction ion and gas flow technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of reduced smoothness of the side walls of through holes, reduced etching efficiency, etc., to achieve good smoothness and reduce switching Time, the effect of improving etching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

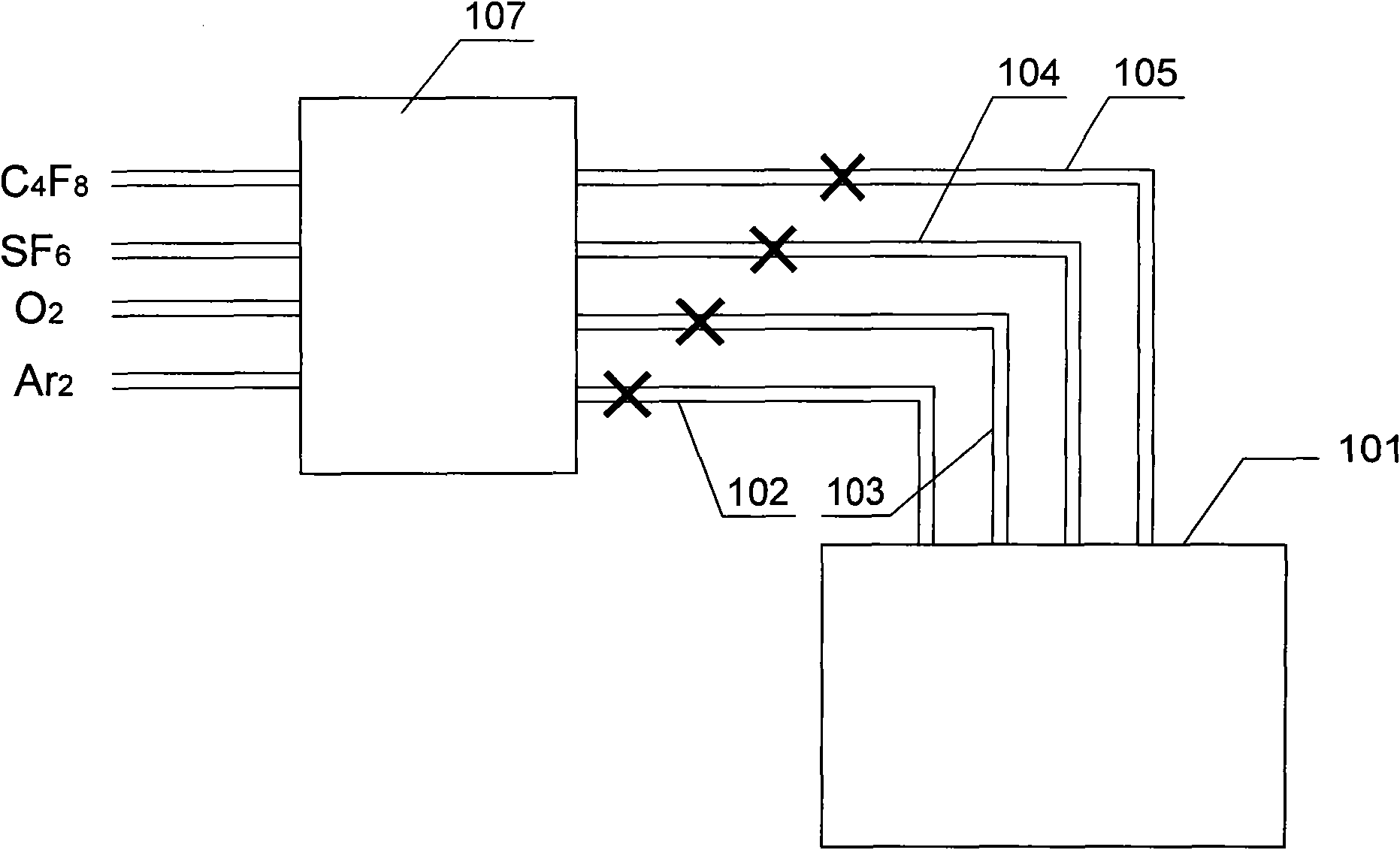

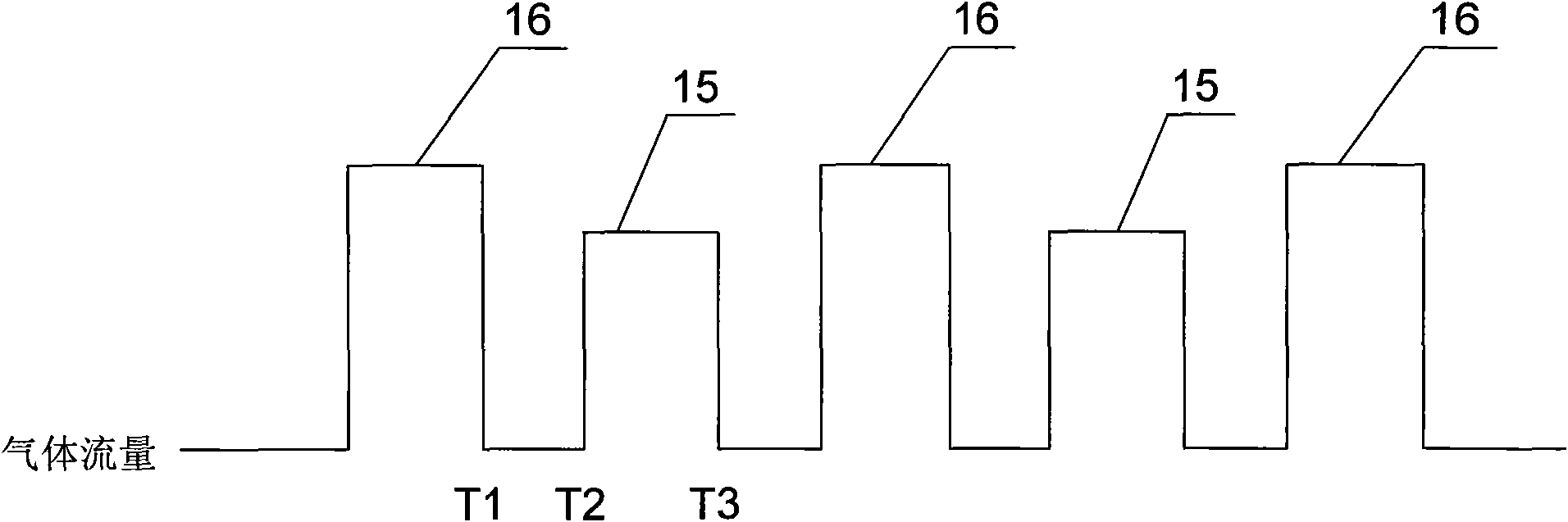

[0023] Figure 4 Shown is a schematic diagram of the gas flow control device provided by the present invention. Such as Figure 4 As shown, the gas flow device includes a chamber 301, a pipeline 302 for passing Ar gas, and a pipeline for passing O 2 Gas pipeline 303, through SF 6 Gas pipeline 304, through C 4 f 8 Gas pipeline 305, MFC and MFC control module 310, the gas flow control device is used for gas flow control in the deep reactive ion etching process, the wafer to be etched is placed in the chamber 301, and the pipelines 302, 303 MFC312, 313, 314, 315 are respectively set in , 304, 305, and the MFC control module 310 can control MFC312, 313, 314, 315 at the same time. Real-time control of the flow, therefore, the gas flow flowing through each pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com