SCR (selective catalyst reduction) injector head of diesel engine

A diesel engine and injection head technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of urea solution clogging pipelines, and achieve the effects of avoiding clogging pipelines, convenient maintenance, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

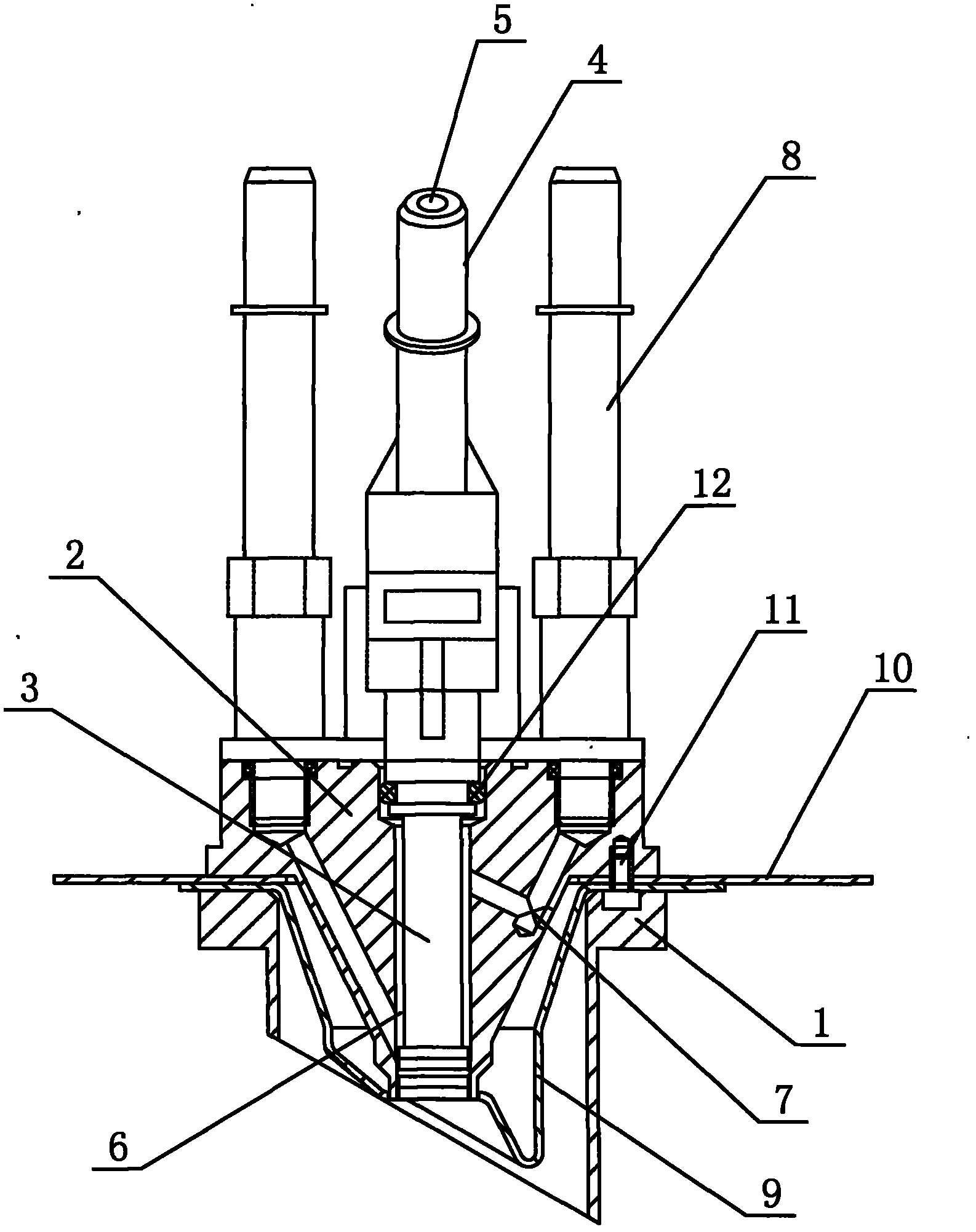

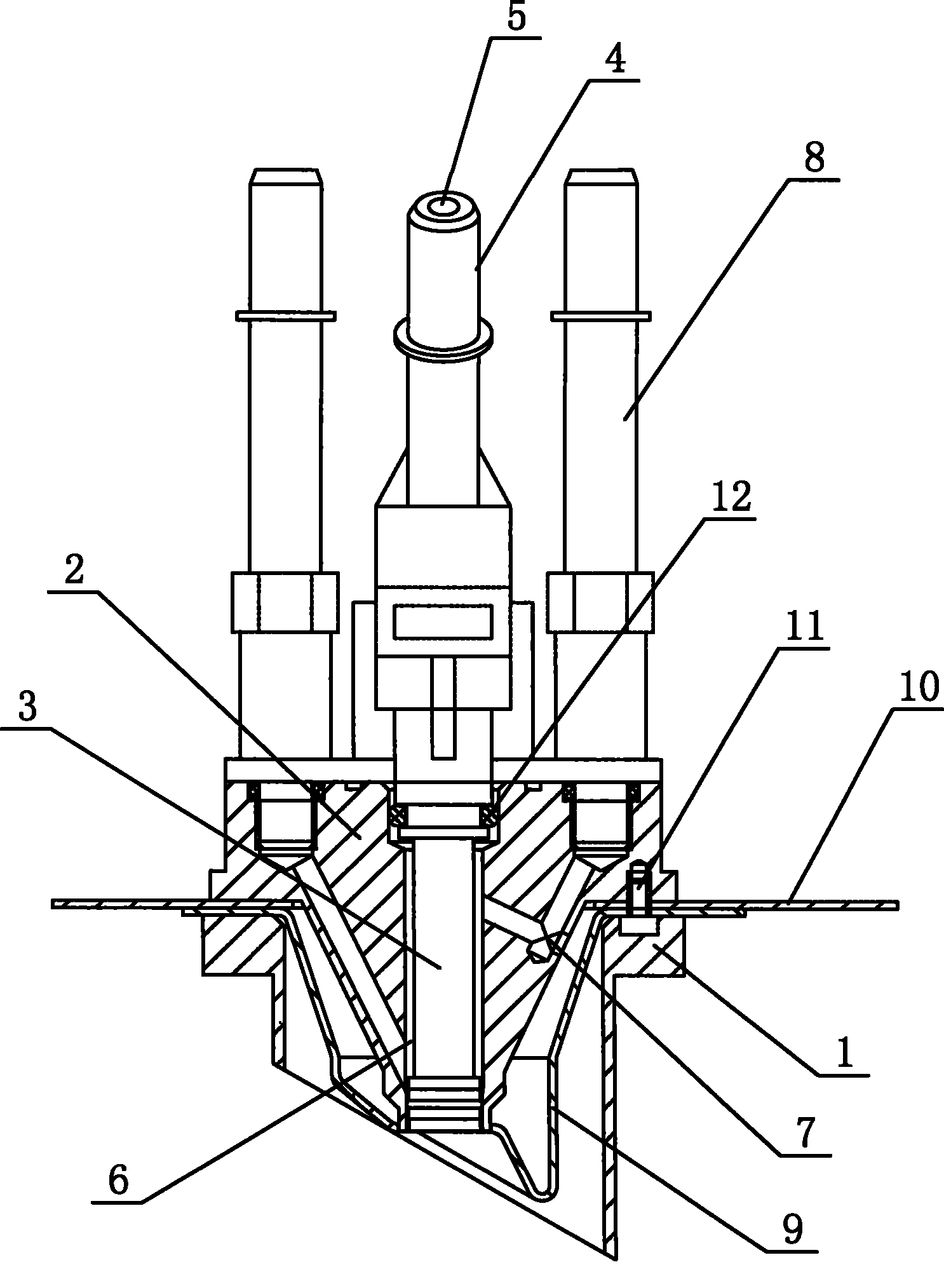

[0016] Please refer to figure 1 as shown, figure 1 It is a schematic diagram of the structure of the diesel engine SCR injection head of the present invention. In this embodiment, a diesel engine SCR injection head includes a mounting seat 1 and a cooling seat 2. The mounting seat 1 is welded on the exhaust pipe of the diesel engine, and is connected with The exhaust pipe of the diesel engine is connected, the cooling seat 2 is installed on the mounting seat 1 through the fixing screw 11, and the nozzle 3 is arranged in the cooling seat 2, and a water cooling cavity 6 is formed between the nozzle 3 and the cooling seat 2 , the water-cooling cavity 6 communicates with the water-cooling channel 7 provided in the cooling seat 2 to connect to the water pipe joint 8, the water pipe joint 8 is arranged on the cooling seat 2, and a sealing ring is arranged between the nozzle 3 and the cooling seat 2 12, and the nozzle 3 is connected to the upper connection seat 4, and the upper conn...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap