Fruit protection bag with light scattering part as well as manufacturing method and use method thereof

A technology of light scattering and fruiting, which is applied in the direction of plant protection covers, etc., can solve the problems of manufacturing cost, laborious umbrella installation, complex structure, etc., and achieve the effect of saving trouble, increasing sugar content, and replacing bags

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0078] The following examples are given to describe the present invention in detail, but the present invention is not limited to these examples.

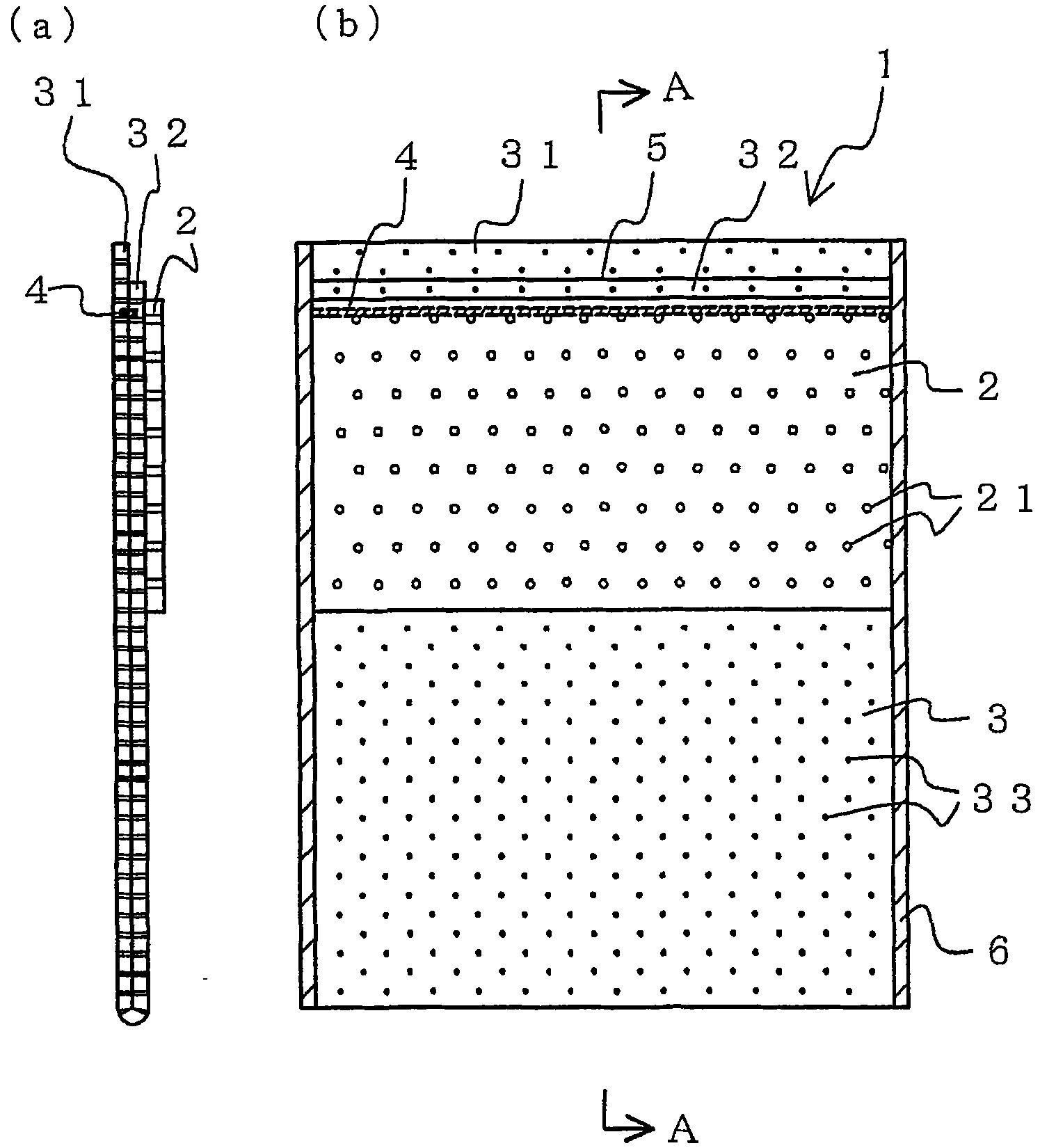

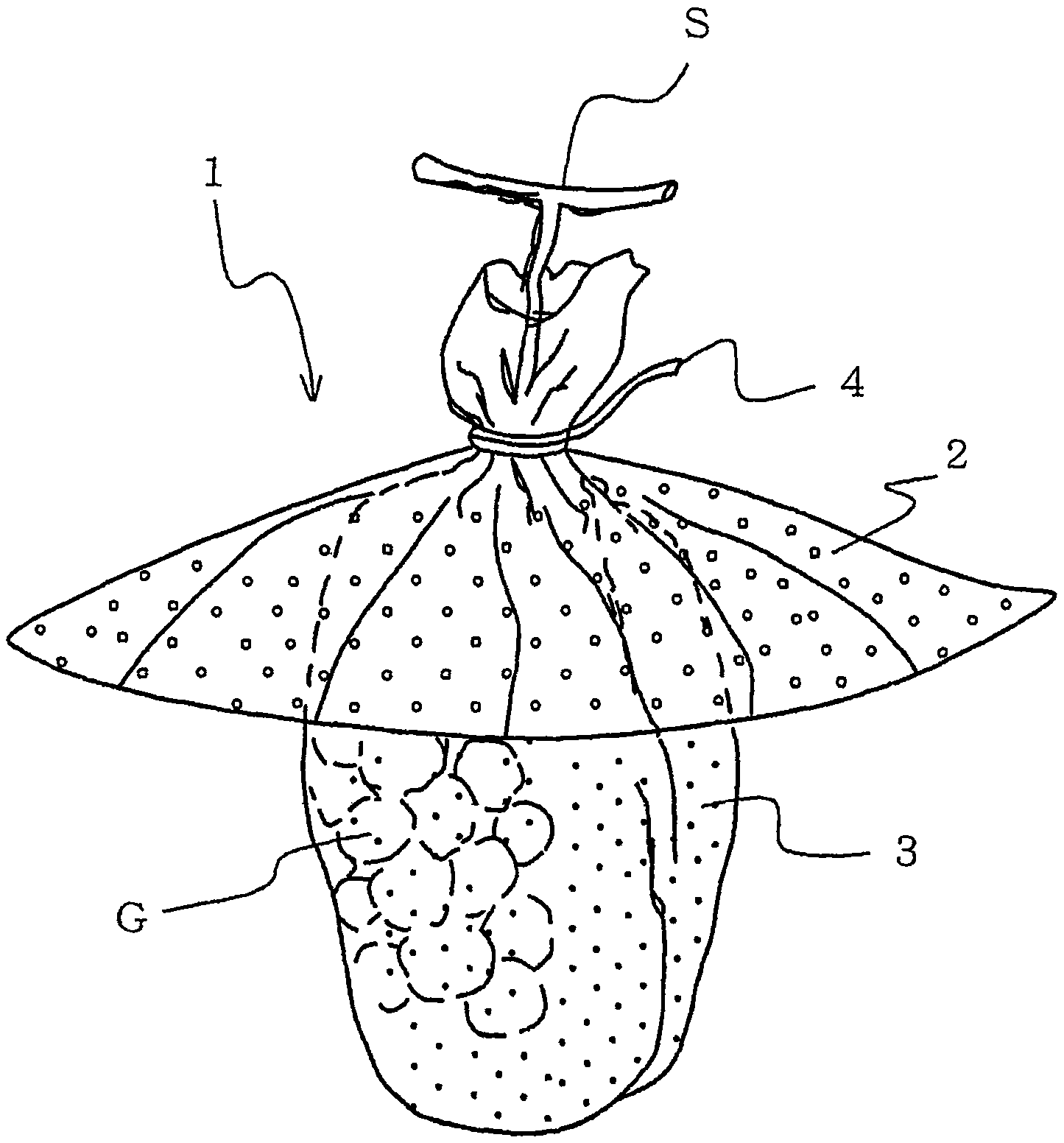

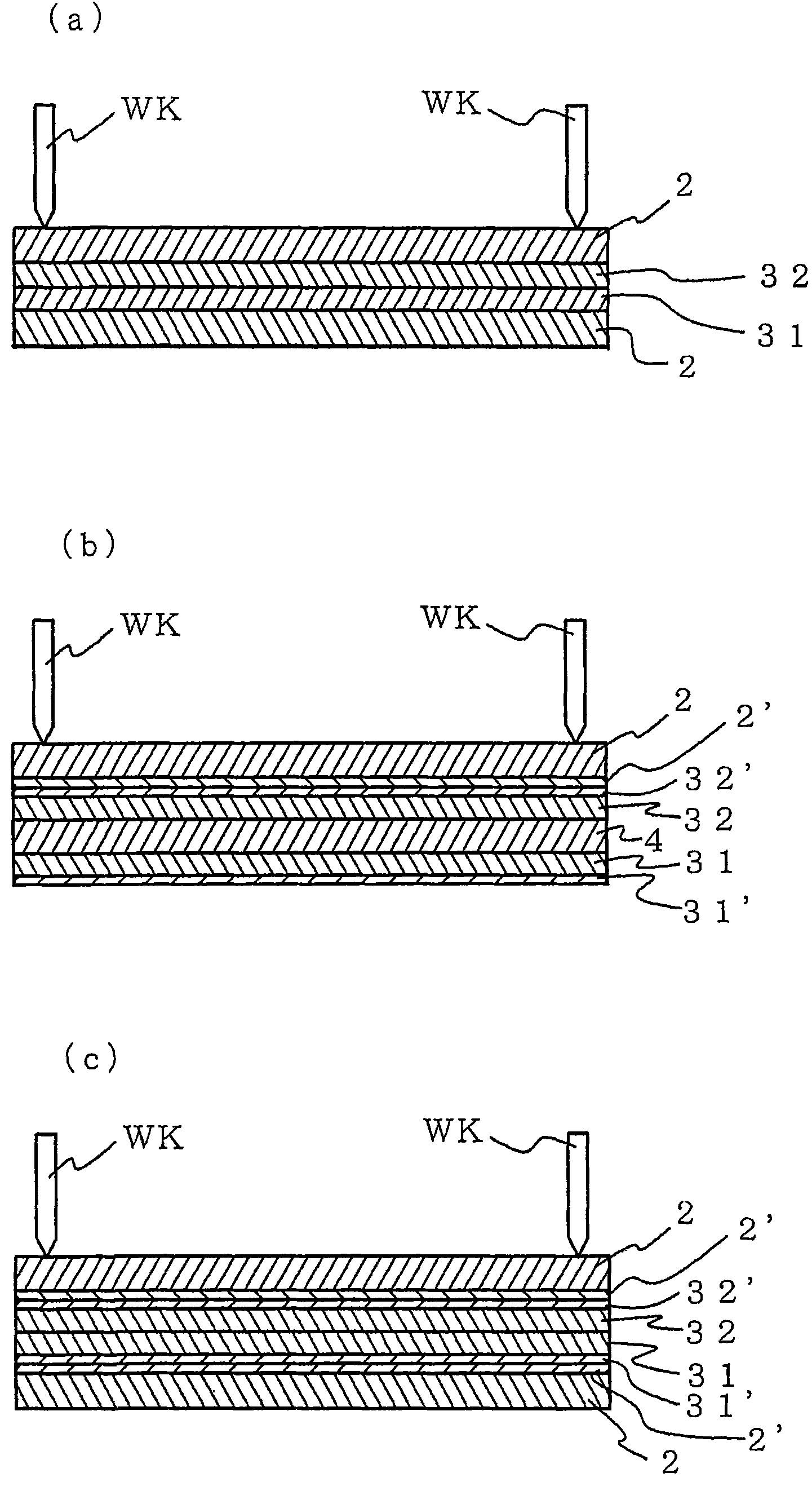

[0079] In this example, as shown in Table 1, a 25 μm thick transparent OPP film is used for the main body of the bag, and the transparent OPP film is provided with holes of 1,786,000 / m on the entire surface of the film 2 , The average pore diameter is 100-130μm, and the average pore area ratio is 1.4%. The air-permeable micro-pores are composed of circular holes. The light-scattering member is provided on the entire surface of the film by ventilating holes with a pore diameter of 1 mm at a pitch of 8 mm. It is composed of a milky white and translucent high-density polyethylene (HDPE) film with a thickness of 20 μm and added with 1 to 3% white coloring agent.

[0080] According to the manufacturing method of one embodiment, a desired fruit protection bag is obtained.

[0081] Table 1

[0082]

[0083] Thirty sheets of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com