Coaxial hollow cathode discharge fraction hydrogen catalytic reaction generator

A hollow cathode discharge and catalytic reaction technology, applied in the production of hydrogen, chemical/physical/physical-chemical processes of energy application, etc., can solve the problems of increased plasma density and temperature, low hydrino reaction intensity, etc. The effect of radiation and evaporation, the enhancement of hydrino catalytic reaction, and the improvement of discharge current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

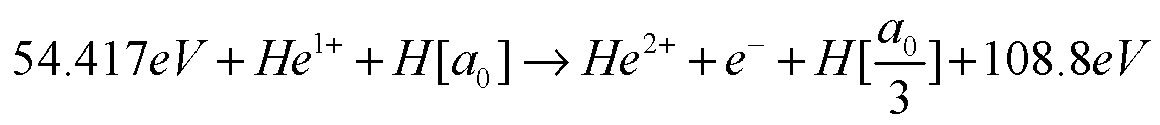

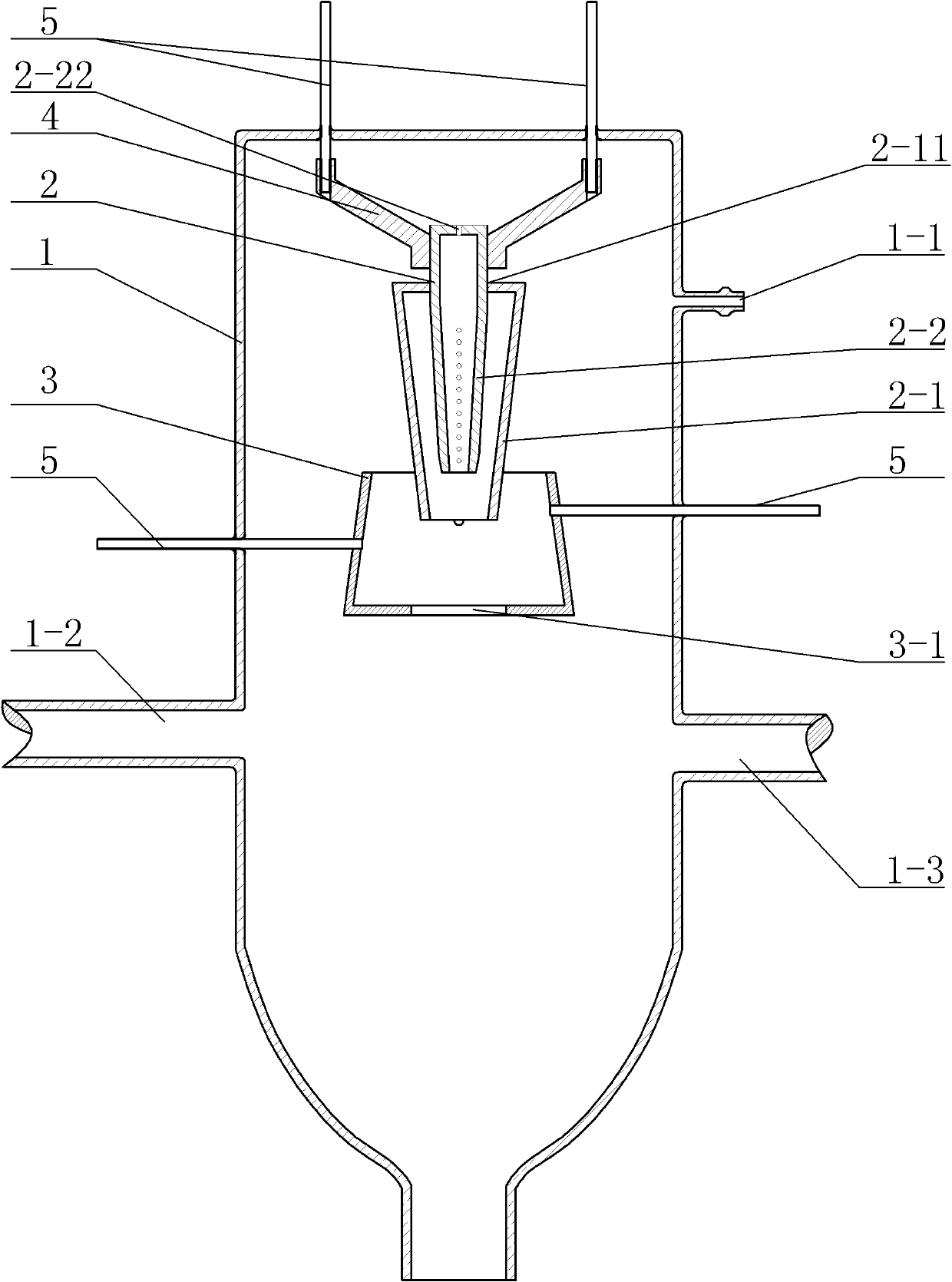

[0021] Specific implementation mode one: the following combination figure 1 figure 2 Describe this embodiment, the coaxial hollow cathode discharge hydrino catalytic reaction generator described in this embodiment includes a reaction vacuum tube 1, and it also includes a double cylinder cathode 2, a single cylinder anode 3, a support 4 and four tungsten rods terminal 5,

[0022] Both the double-tube cathode 2 and the single-tube anode 3 are located in the reaction vacuum tube 1, and are arranged coaxially with the reaction vacuum tube 1. The upper port of the type anode 3 is relatively set,

[0023] There is an anode circular hole 3-1 in the center of the lower bottom surface of the single cylinder anode 3, and a side wall through hole is respectively arranged at the position of the side wall of the single cylinder type anode 3 in the opposite direction, and the through holes of the side wall are respectively penetrated and sealed A tungsten rod terminal 5 is fixed, and th...

specific Embodiment approach 2

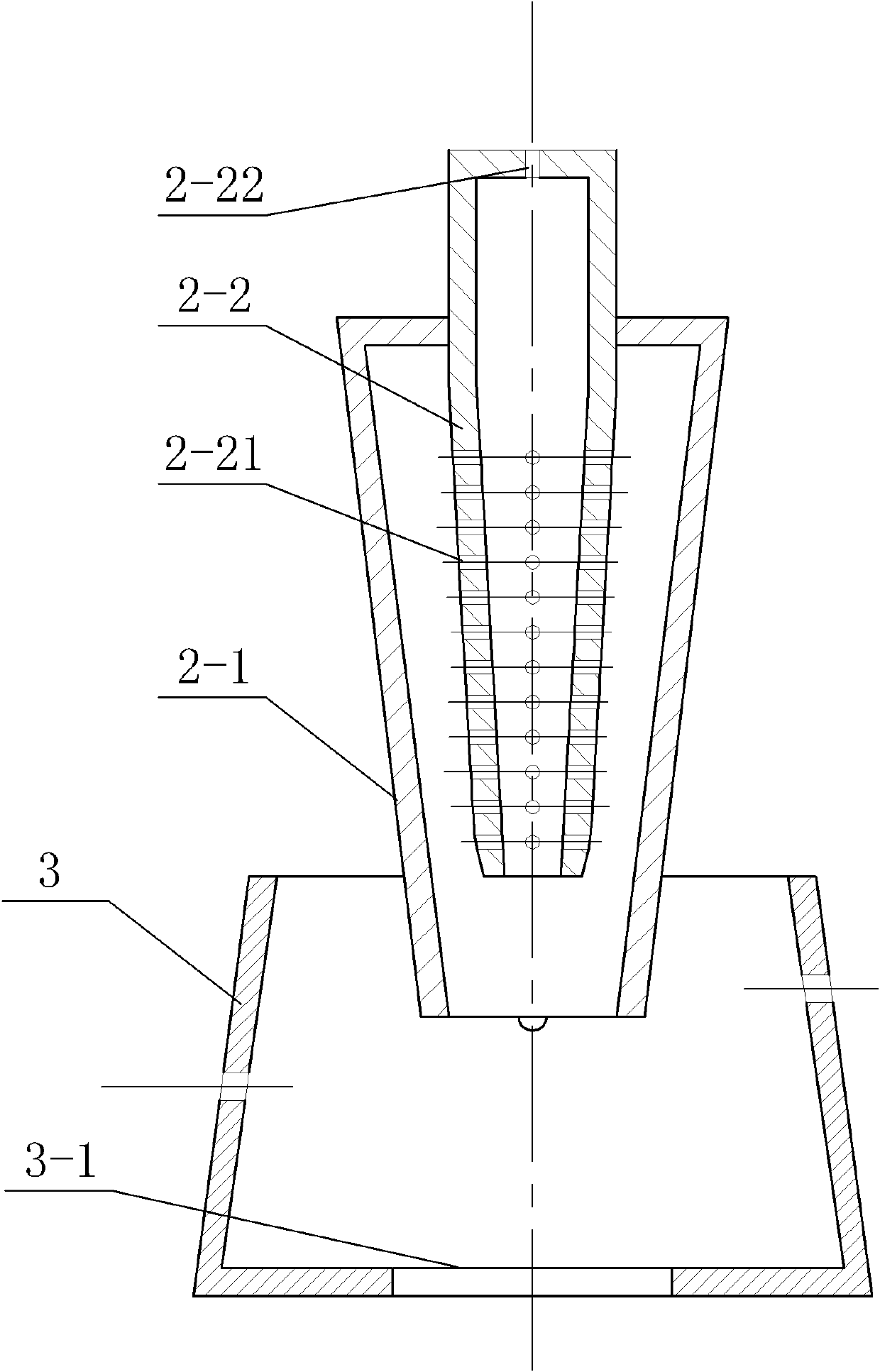

[0028] Specific implementation mode two: the following combination figure 1 This embodiment is described. This embodiment is a further limitation of Embodiment 1. The single-tube anode 3 is in the shape of a truncated cone, and the radius of the upper bottom surface of the single-tube anode 3 is smaller than the radius of the lower bottom surface. Other components and connections are the same as those in Embodiment 1.

specific Embodiment approach 3

[0029] Specific implementation mode three: the following combination figure 1 and figure 2 Describe this embodiment, this embodiment is a further limitation to Embodiment 2, the outer cylinder 2-1 and the inner cylinder 2-2 of the double cylinder type cathode 2 protruding into the outer cylinder 2-1 are all in the shape of a truncated cone , and the radius of the upper bottom surface of the truncated cone is greater than the radius of the lower bottom surface, and the center of the upper bottom surface of the inner cylinder 2-2 has an inner cathode hole 2-22. Other components and connections are the same as those in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com