Catalyst for producing alpha, alpha-dimethyl benzyl alcohol by hydrogenation of cumene hydroperoxide and preparation method thereof

A technology of cumene hydroperoxide and dimethyl benzyl alcohol, which is applied in the field of catalysts and its preparation, and can solve the problems of poor stability of Pd catalysts and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

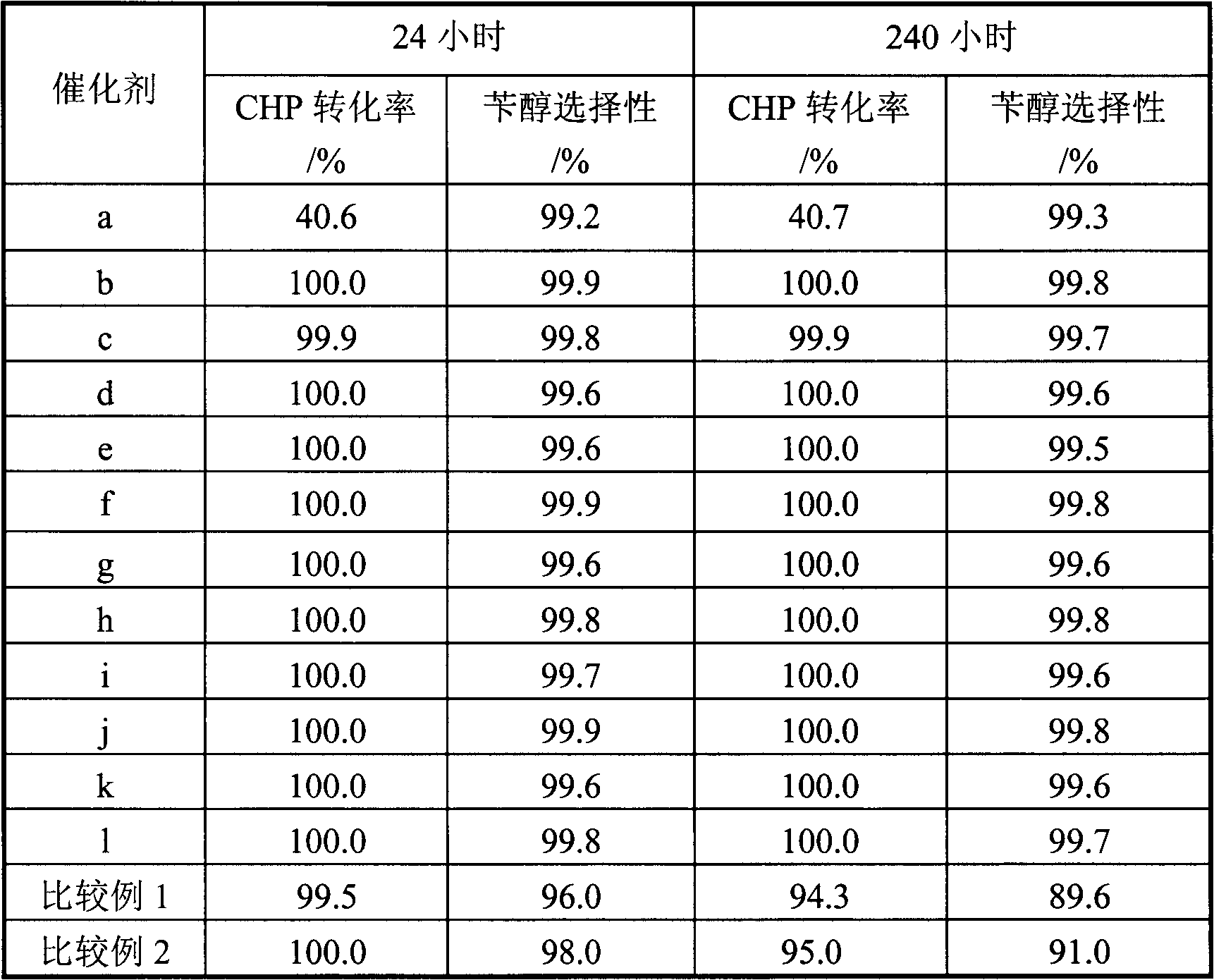

Examples

Embodiment 1

[0013] Formed Al 2 o 3 After drying at 120°C for 6 hours and calcining at 600°C for 4 hours to obtain a carrier (specific surface is 208m 2 / g, the pore volume is 0.78mL / g, and the average pore diameter is 12.5nm). The carrier is impregnated with the mixed salt solution containing the required amount of Pb, Na and Pd components, dried at 120°C for 4 hours and calcined at 550°C for 4 hours to obtain a weight percentage of 0.1%Pd-0.1%Pb-0.1%Na / Al 2 o 3 Catalyst a.

Embodiment 2

[0015] Formed Al 2 o 3 After drying at 120°C for 6 hours and calcining at 750°C for 4 hours to obtain a carrier (specific surface is 200m 2 / g, the pore volume is 0.69mL / g, and the average pore diameter is 13.2nm). Impregnate the carrier with the mixed salt solution containing the required amount of Pd, Sn and In components and dry at 120°C for 4 hours, then impregnate the carrier with the mixed solution containing the required amount of K and Mg components, and dry at 120°C for 4 hours Hours and 550 ° C for 4 hours to produce 0.5% Pd-2.0% Sn-1.0% In-0.5% K-1.5% Mg / SiO in terms of weight percentage 2 Catalyst b.

Embodiment 3

[0017] Al after molding 2 o 3 After drying at 120°C for 6 hours and calcining at 1200°C for 2 hours to obtain a carrier (specific surface is 75m 2 / g, the pore volume is 0.28mL / g, and the average pore diameter is 24.6nm). The carrier is impregnated with the solution containing the required amount of Mg component, dried at 120°C for 4 hours, then impregnated with the mixed solution containing the required amount of Pd and Pb, dried at 120°C for 4 hours and calcined at 550°C for 4 hours. 0.5%Pd-1.0%Pb-10.0%Mg / Al by weight 2 o 3 Catalyst c.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com