Eccentric grinding machine

A grinding machine and eccentric technology, applied in the field of grinding machines, can solve the problems of high requirements for the use environment, long grinding time, sample pollution, etc., and achieve the effect of shortening the grinding time, improving the grinding efficiency, and low requirements for the use environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

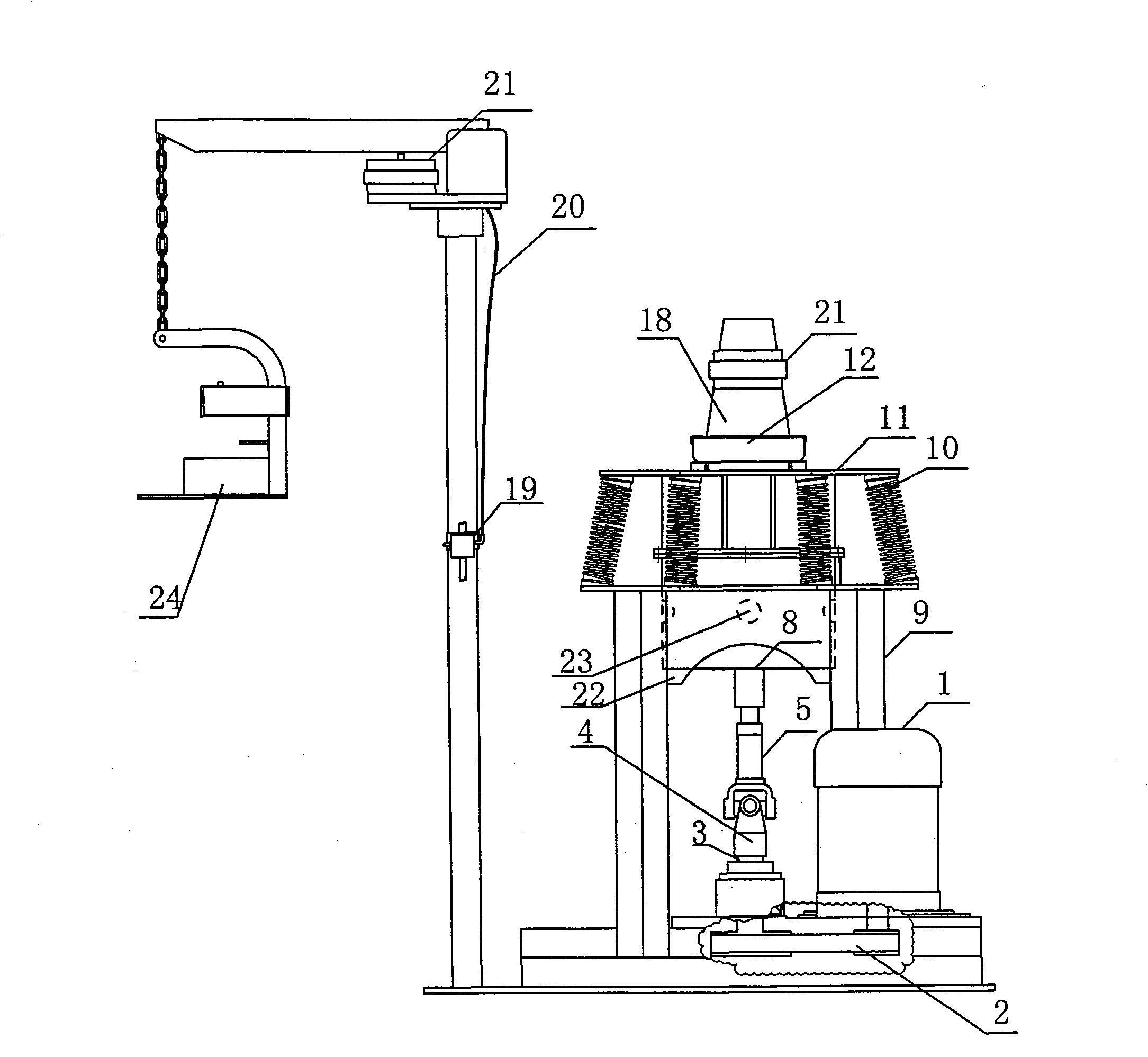

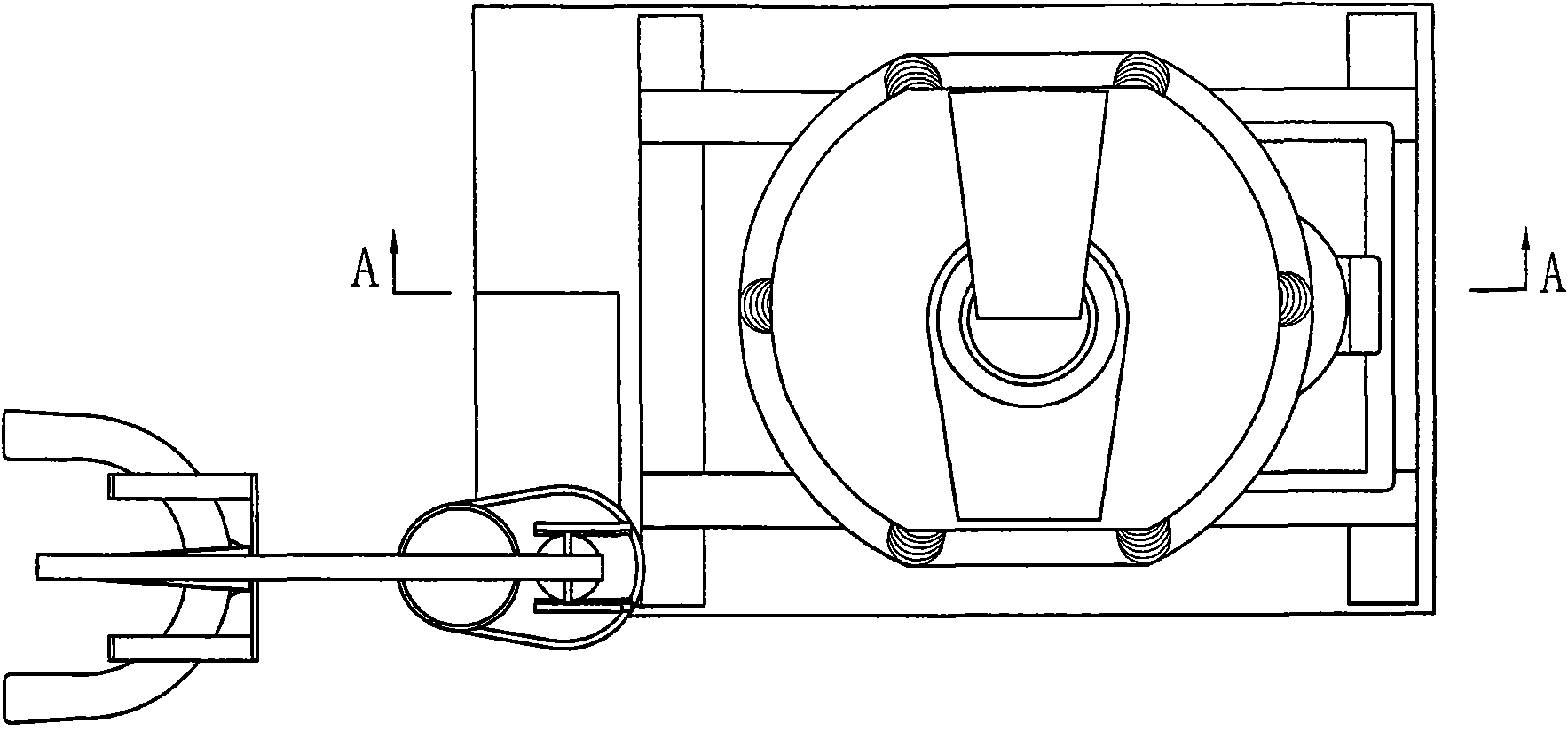

[0034] Specific embodiment one. refer to Figure 1 to Figure 5 , the first embodiment of the present invention will be described.

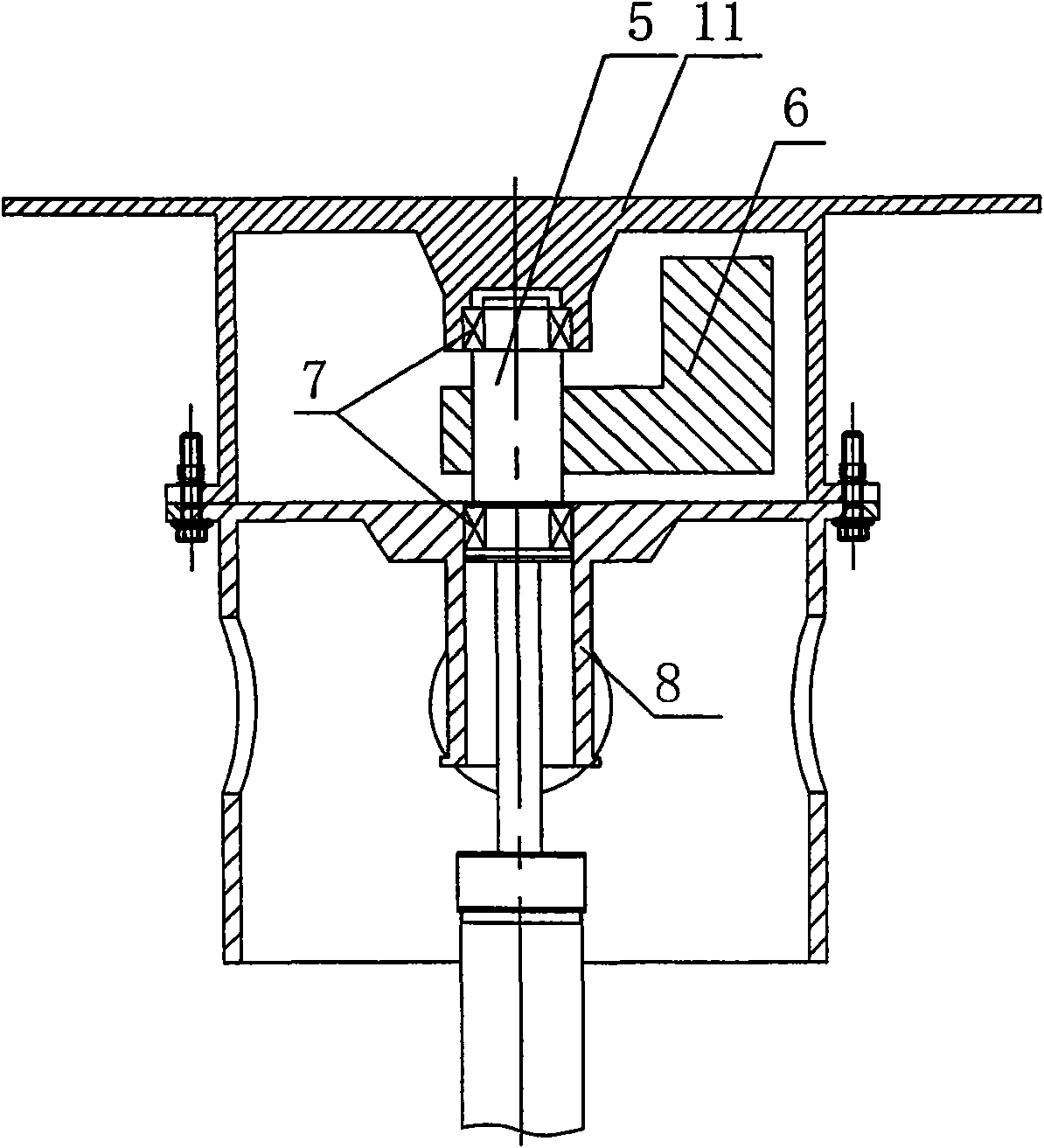

[0035] The drive motor 1 of the eccentric grinder is connected with the input shaft 3 through the belt transmission device 2; the input shaft 3 and the output shaft 5 are respectively connected with both ends of the universal joint 4, and the transmission eccentric block 6 is fixed on the output shaft 5 and the two The center of gravity is not on a straight line in the vertical direction; according to the different fixed positions of the transmission eccentric block 6, two embodiments of the present invention are formed, and the positions are as follows image 3 and Image 6 . The grinding platform 11 has a hollow base, the hollow base is fixedly connected with the sleeve 8, the upper surface of the sleeve 8 has a circular hole in the center, and the bearing 7 at the lower part of the output shaft 5 just falls into the hole. The table surface ...

specific Embodiment 2

[0038] Specific embodiment two. The difference from Example 1 is that Image 6 , the lower surface of the grinding platform 11 is tightly pressed on the transmission eccentric block 6. At this time, friction will be generated between the two. Since the transmission eccentric block 6 is driven by the output shaft 5 and rotates at a variable speed at the same time, under the action of friction, the grinding Platform 11 just shakes constantly in horizontal direction, produces larger amplitude; Output shaft 5 makes irregular circular motion around itself at the same time, will produce height difference in vertical direction, add the gravity of grinding platform and its upper part itself, grinding The platform 11 also generates vibration amplitude in the vertical direction at the same time. As a result, the grinding platform 11 generates vibration amplitudes in the horizontal direction and the vertical direction, causing the grinding disc to continuously collide with the bowl, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com