Preparation method for sintered copper powder material of heat pipe

A manufacturing method and sintering technology, which is applied in the field of manufacturing sintered copper powder materials, can solve the problems that copper powder is not easy to adhere to the inner wall of the heat pipe, and is easy to fall off, so as to achieve the effect of reducing energy consumption and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention are described in detail below. The invention is not limited to the specific examples. In this specification, all parts are parts by weight, all percentages are percentages by weight, and all temperatures are in degrees Celsius. The specific method is as follows:

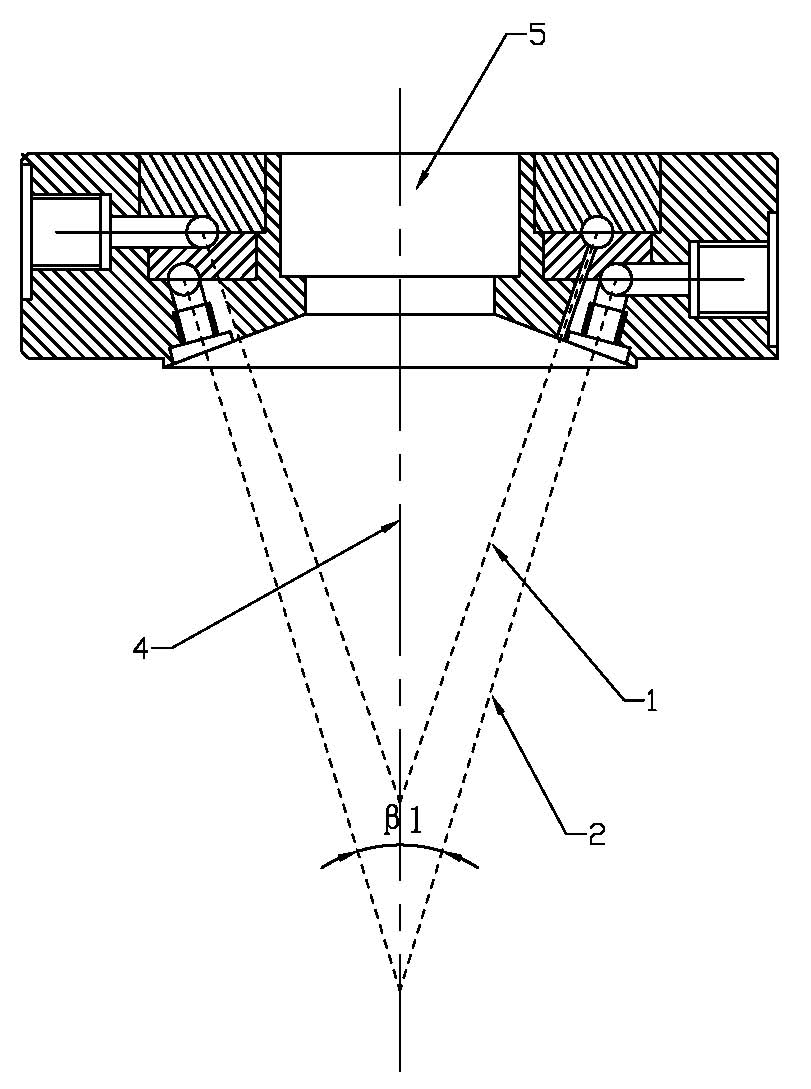

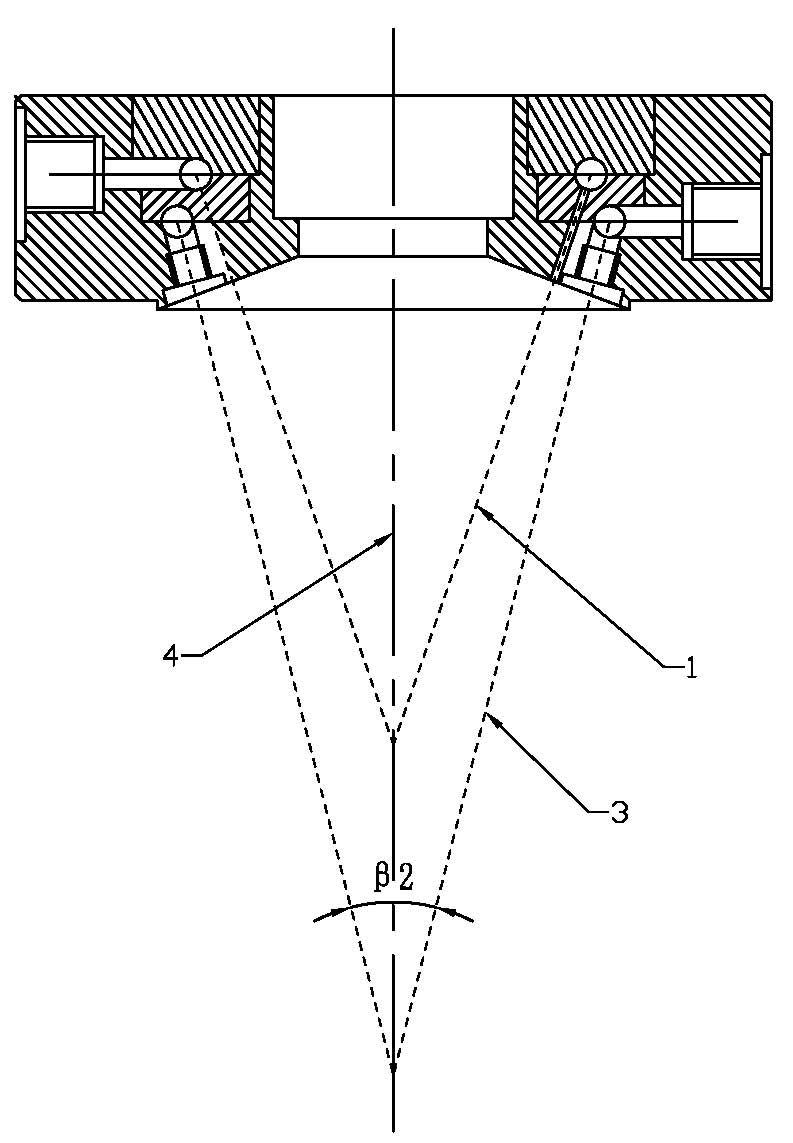

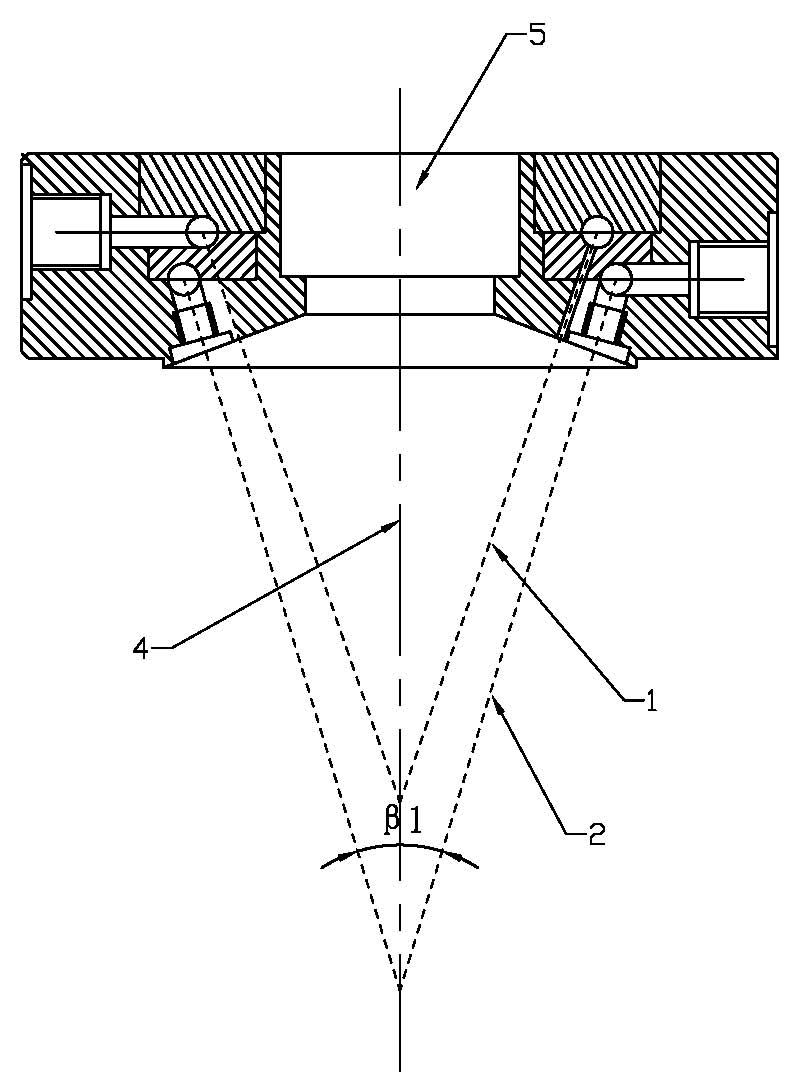

[0025] Select 500kg of bright copper, copper rice or electrolytic copper with a purity of 99.9%, add it to the intermediate frequency induction furnace for melting in batches, start the induction furnace melting of the intermediate frequency furnace, and start blowing oxygen with a graphite tube when liquid copper liquid appears at 1083°C, and use the copper liquid to continuously measure oxygen The sensor directly fixes oxygen to maintain an oxygen content of 0.1-1% on the surface of the copper melt. After the copper liquid is dissolved in oxygen, the surface tension decreases, which can reduce the standard deviation of the particle size distribution, making it easier to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com