Pneumatic hammer

A nail hammer and pneumatic technology, which is applied in the field of automatic hitting installation tools for round nails, can solve problems such as easy hitting of fingers, low work efficiency, and high labor intensity, and achieve the goals of simple and convenient use, reliable performance, and improved efficiency and quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

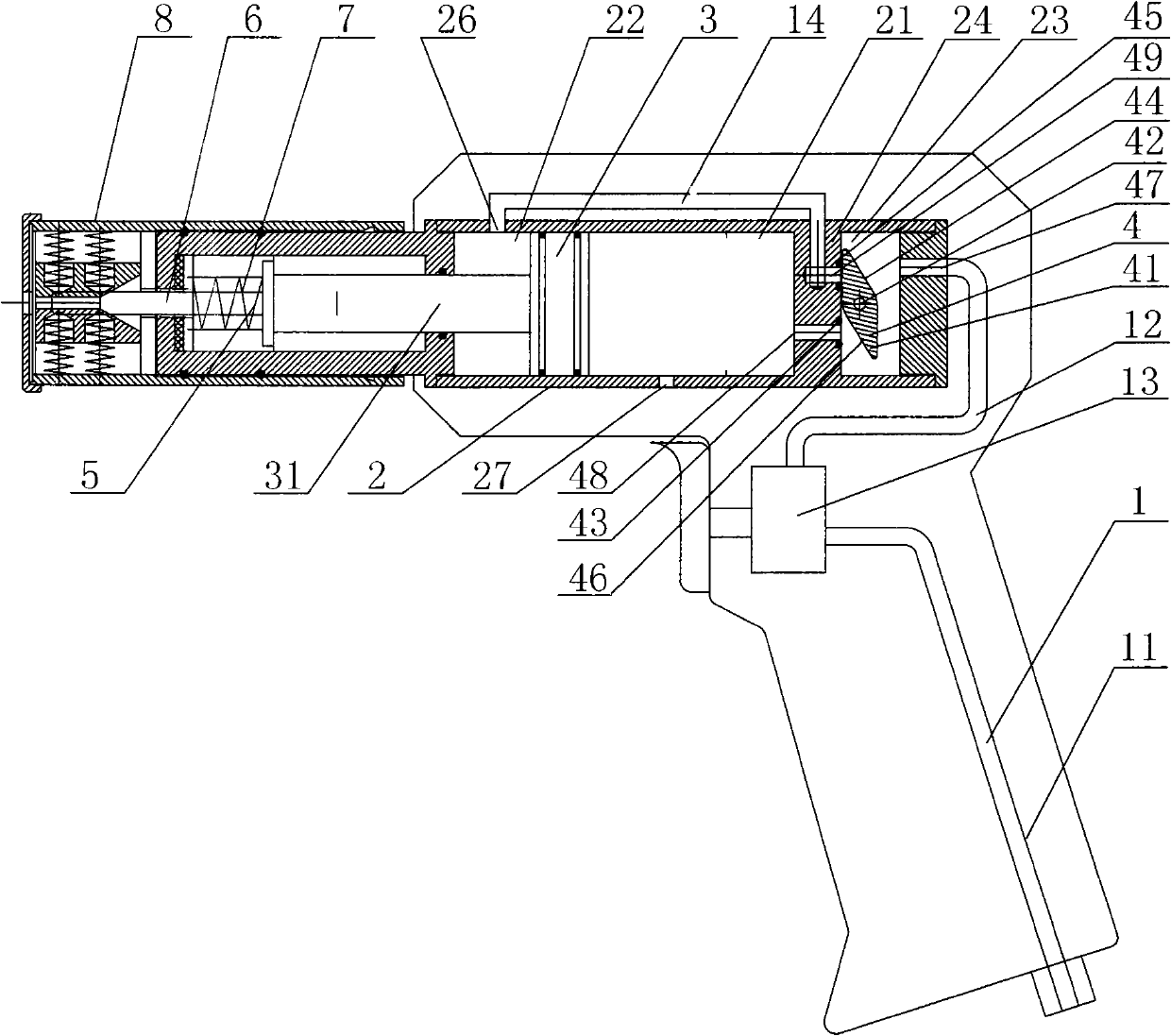

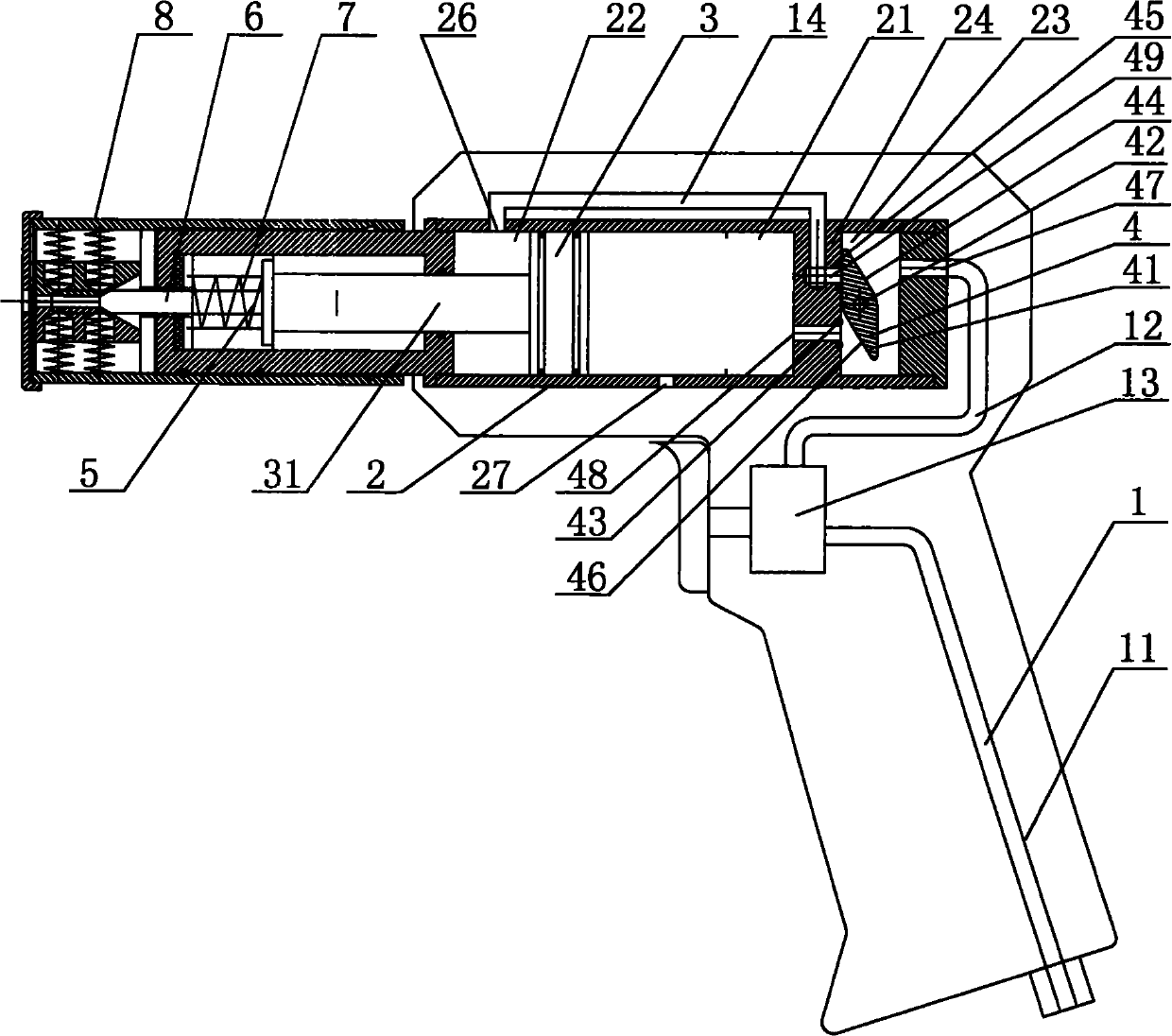

[0020] See attached figure 1 , a pneumatic hammer, including an air supply device 1, a cylinder 2 with a first chamber 21, a second chamber 22 and a third chamber 23, a piston 3, an air flow switching valve 4, a piston reset device 5, and a striking device 6. Air supply device 1 is made up of intake pipe 1 (11), intake pipe 2 (12), intake pipe 3 (14) and intake switch 13. A piston 3 for separating the first chamber 21 and the second chamber 22 is arranged in the cylinder, and the piston rod 31 of the piston (3) passes through the second chamber 22 in an airtight manner and is connected with the beating device 6 . Set the exhaust port C3 on the cylinder 2, set the intake port C2 (26) on the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com