Zoning temperature control drum for microstructure replication

A technology of microstructure and rollers, which is applied in the field of hot pressing rollers, can solve the problem that the hot pressing rollers cannot reproduce the surface microstructure sheet of structural size, and achieve the effect of shortening the production cycle and accelerating the cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

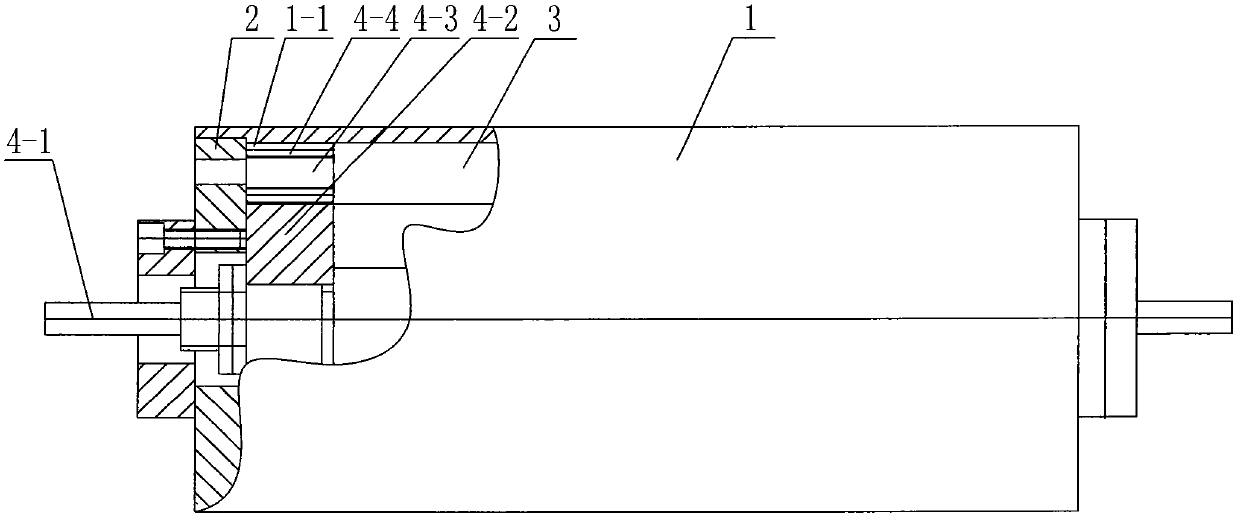

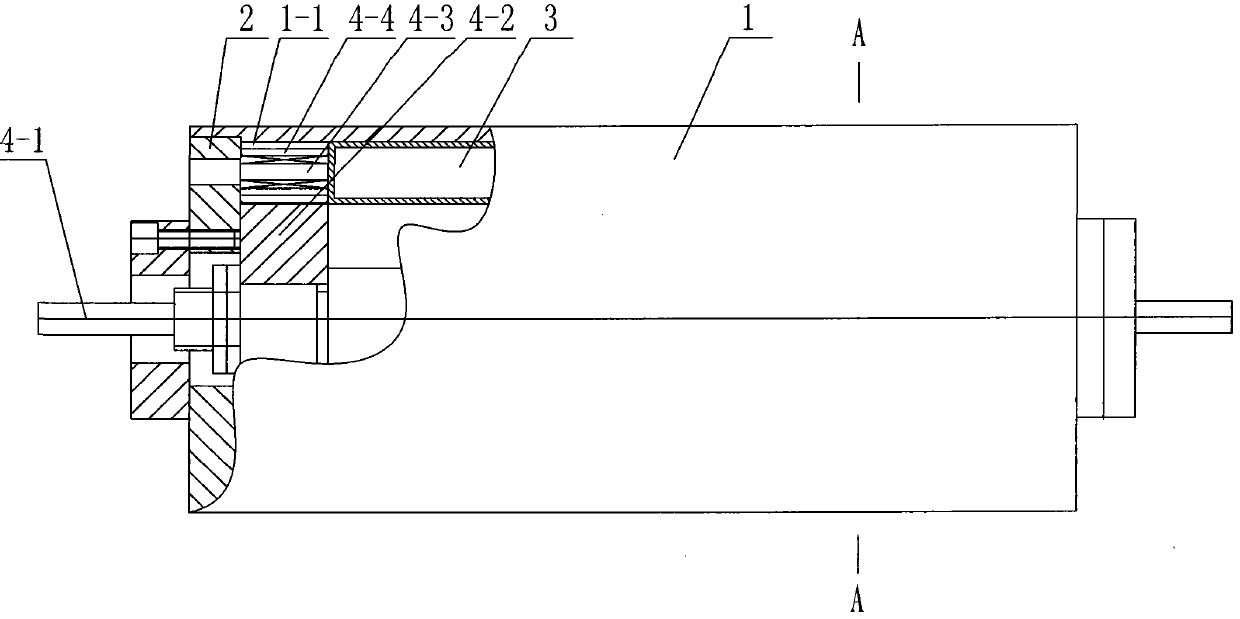

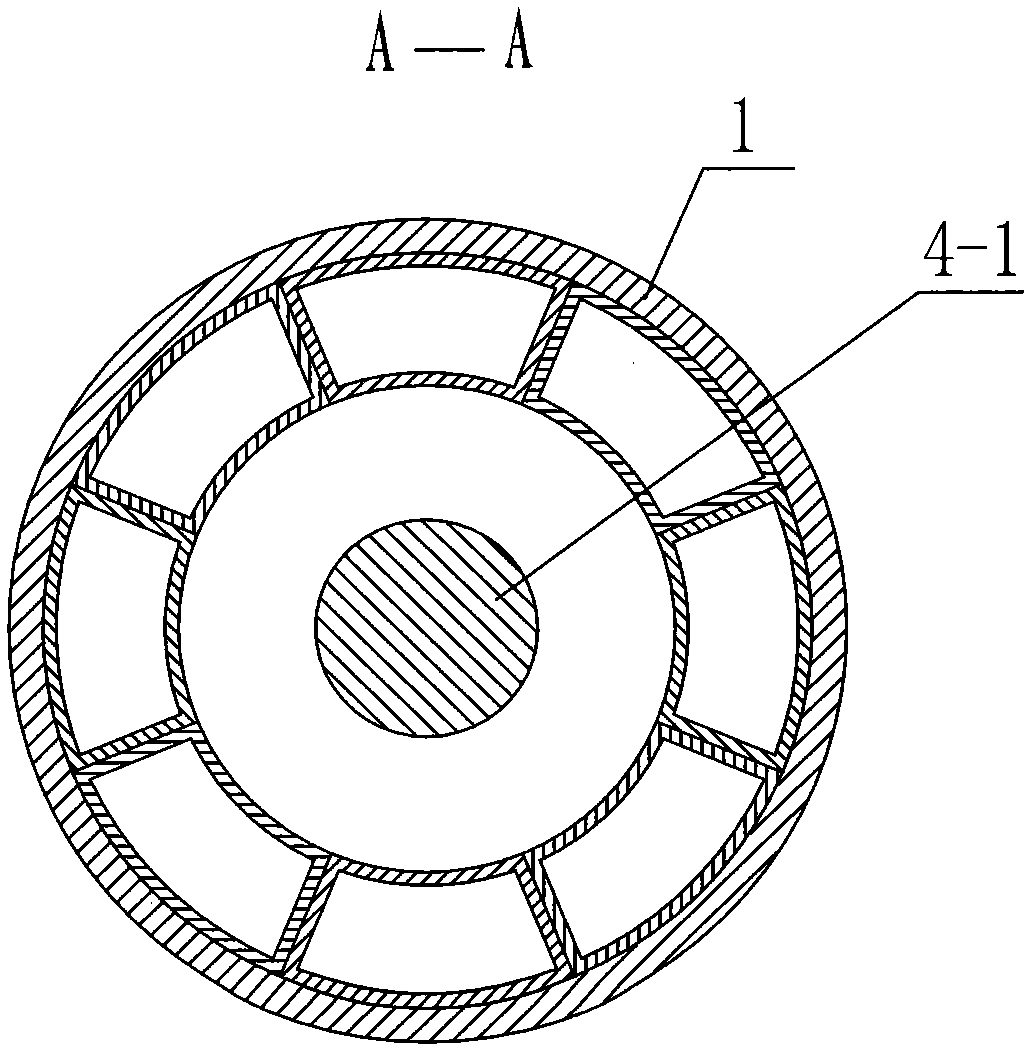

[0030] Such as figure 1 The first embodiment of the partitioned temperature-controlled roller for microstructure replication of the present invention shown has a cylinder body 1 and an end cap 2, and the end cap 2 is clearance fit with the cylinder body 1 for partitioning of microstructure replication The circumference of the temperature-controlled roller is divided into two or more regions. In order to make the surface temperature change of the temperature-controlled roller body 1 of the partitioned temperature-controlled roller for microstructure replication better match the product process requirements, the size of each region is different. . There is one or more cylinder heating devices for heating the cylinder in at least one area, and the surface temperature of the cylinder 1 in different areas is different; the partition temperature control for microstructure replication The roller also has a cylinder driving mechanism 4 that drives the cylinder 1 to rotate around the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com