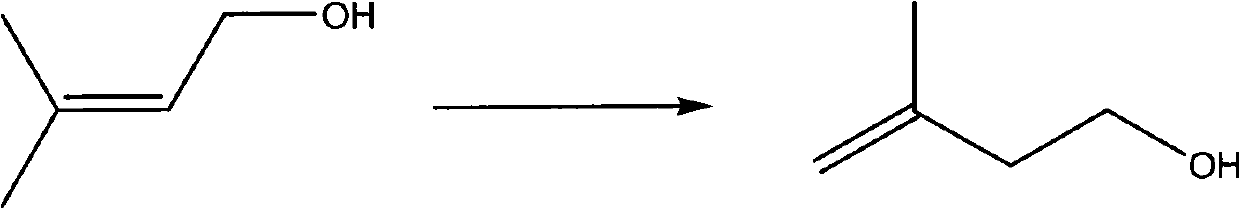

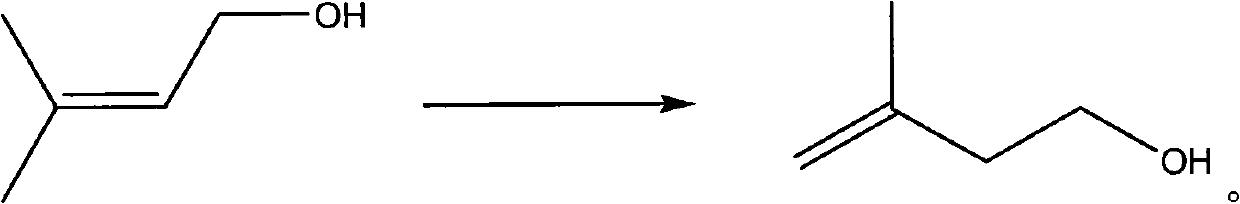

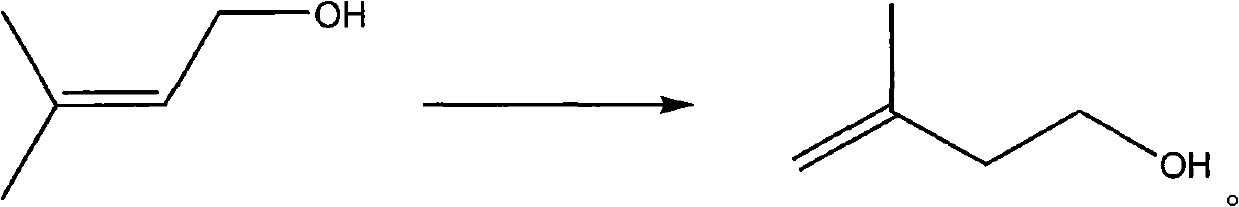

Method for preparing 3-methyl-3-butene-1-alcohol

A technology of butene and methyl, which is applied in the field of preparation of 3-methyl-3-buten-1-ol, can solve the problems of high production cost and large investment, and achieve production cost reduction, low energy consumption, and conversion high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

[0030] The general methods of Examples 1-10 are as follows:

[0031] The reaction is carried out in a catalytic distillation equipment, which is composed of an isomerization reactor and a rectification column. The reactor is A 25mm×510mm glass fluidized bed reactor is equipped with a baffle full of small holes and a hydrogen gas distributor at the bottom. The small hole diameter of the baffle and distributor is about 0.01mm, and the raw material inlet and gas distributor are located on the baffle. under. The top of the reactor is connected with a rectification column, the theoretical number of trays of the rectification column is 30, and a condensing reflux device with a discharge port and a vacuum interface is installed on the top of the rectification column.

[0032] 600 grams of prenol is added to the reactor, and then 20 grams of Pd / Al with a particle size of 0.03~0.05mm 2 O 3 The catalyst is added to the reactor, and the catalyst is placed on the baffle. Use a vacuum pump t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com