High efficient laundry detergent

A high-efficiency laundry detergent and fat technology, applied in the field of laundry detergent, can solve problems such as weak detergency of laundry detergent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

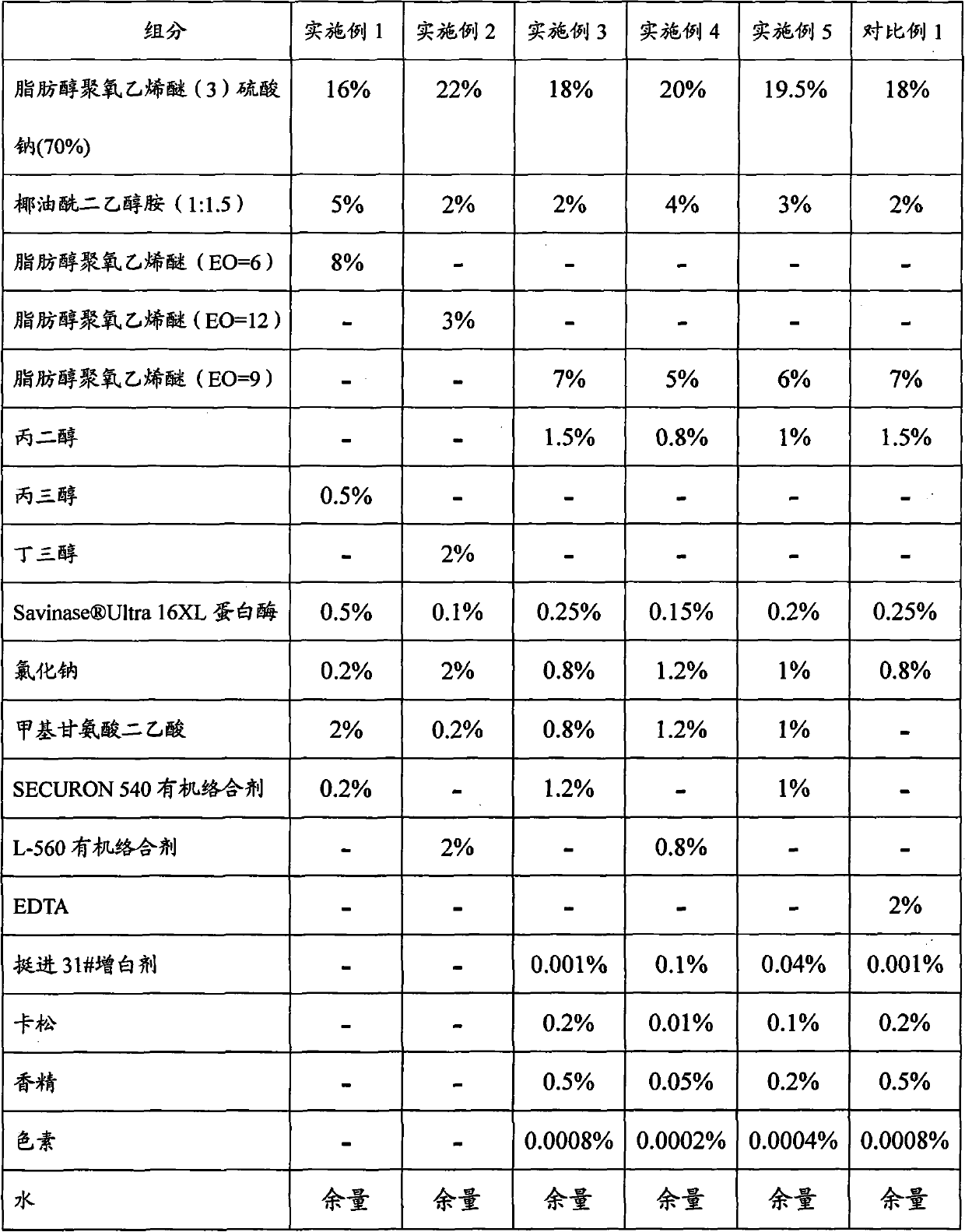

[0064] According to the corresponding embodiment 1 component and content specified in Table 1, carry out raw material weighing.

[0065] In the mixing tank, put water, under stirring condition, add fatty alcohol polyoxyethylene ether (3) sodium sulfate, cocoamide diethanolamine (1:1.5), fatty alcohol polyoxyethylene ether (EO=6-12) and C3-4 polyhydric alcohol, then add methyl glycine diacetic acid, SECURON 540 or L-560 organic complexing agent, then use sodium chloride to adjust the viscosity, and finally add protease to obtain the high-efficiency laundry detergent of the present invention.

Embodiment 2

[0067] According to the specified corresponding embodiment 2 components and contents in Table 1, the raw materials were weighed. According to the preparation method of Example 1, the high-efficiency laundry detergent of the present invention is produced.

Embodiment 3

[0069] According to the corresponding embodiment 3 components and content specified in Table 1, carry out raw material weighing.

[0070] In the mixing tank, put water, under stirring condition, add fatty alcohol polyoxyethylene ether (3) sodium sulfate, cocoamide diethanolamine (1:1.5), fatty alcohol polyoxyethylene ether (EO=6-12) and C3-4 polyols, then add Jinjin 31# brightener, Kathon, methyl glycine diacetic acid, SECURON 540 or L-560 organic complexing agent, pigment and flavor, then use sodium chloride to adjust the viscosity, and finally The high-efficiency laundry detergent of the present invention can be obtained by adding protease.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com