Device and method for detecting and controlling slag state of converter

A converter slag and state detection technology, applied in the direction of furnace control devices, furnaces, furnace components, etc., can solve problems such as noise blocking, inaccurate detection, and limited use range, so as to ensure detection accuracy, calculation accuracy, and reduce converter The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

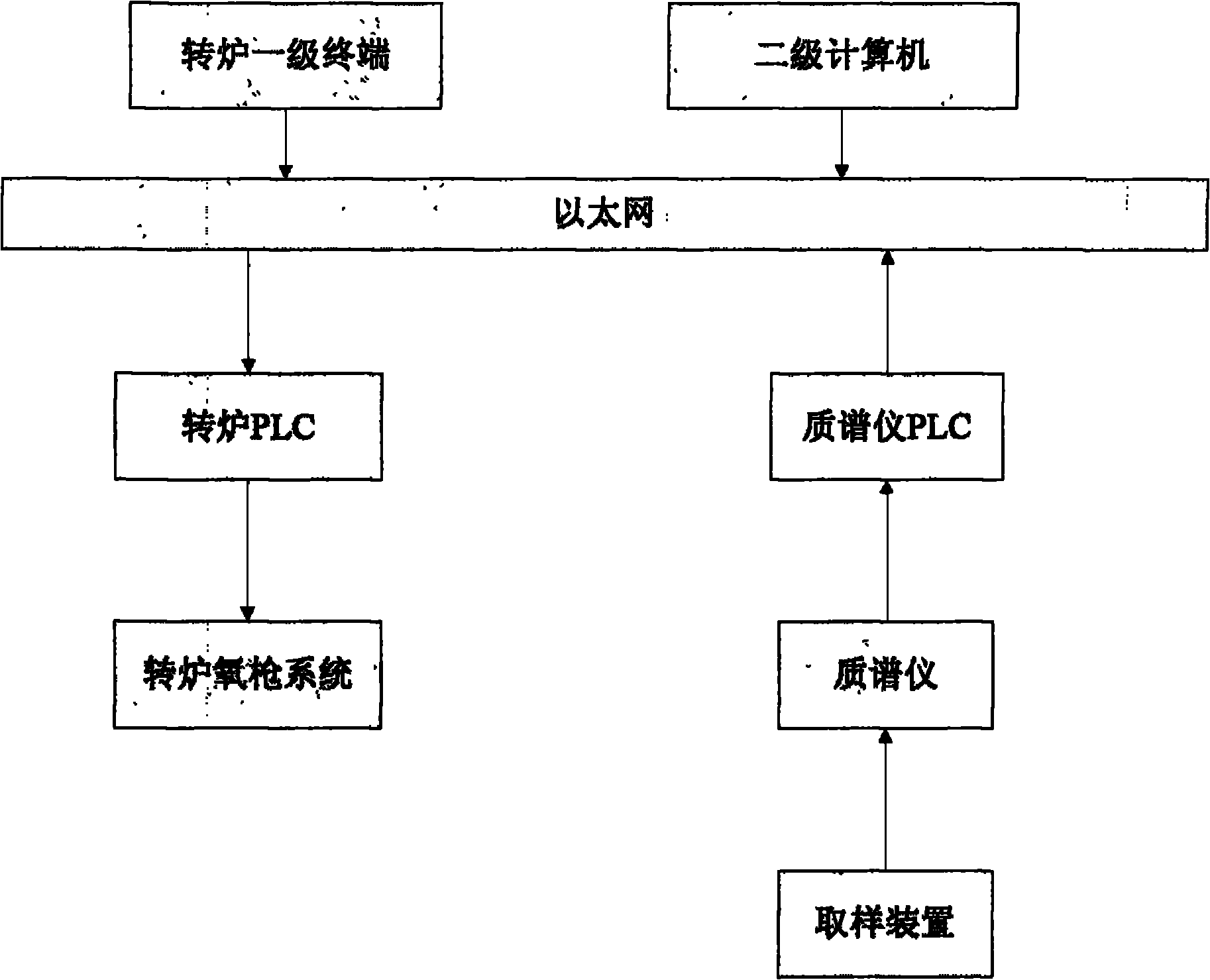

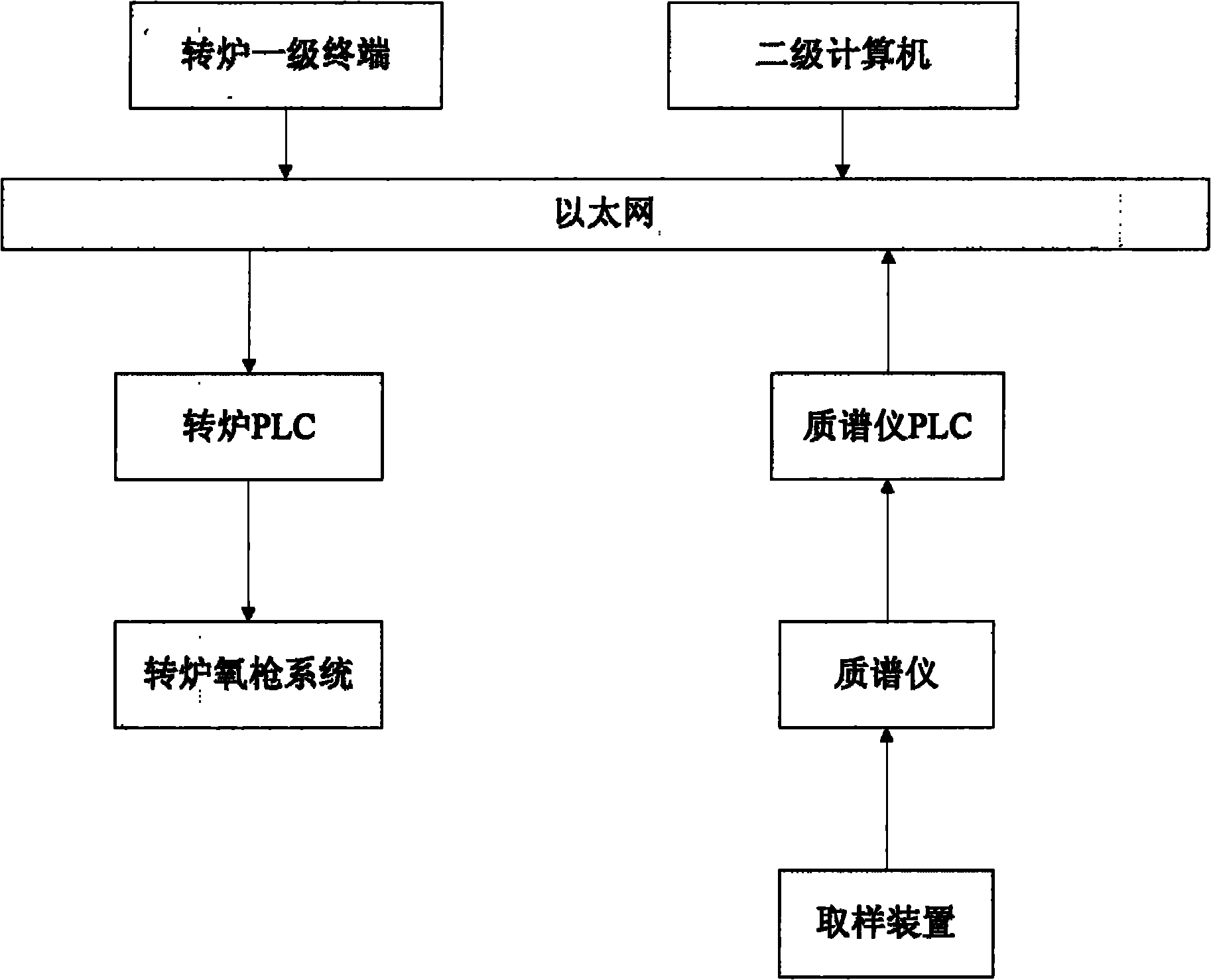

[0018] As can be seen from the drawings, the converter slag state detection and control device of the present invention is mainly composed of a sampling device, a mass spectrometer, a mass spectrometer PLC, a converter secondary computer, a converter primary terminal, Ethernet, a converter primary computer and an oxygen lance system. The sampling device is connected to the mass spectrometer, the mass spectrometer is connected to the mass spectrometer PLC, the mass spectrometer PLC is connected to the secondary computer to form an industrial Ethernet network, the secondary computer is connected to the primary computer, and the primary computer controls the oxygen lance system in real time to adjust the gun position and flow rate. The first-level terminal performs real-time data and status display for the whole process of detection and control. The specific structure and connection method are:

[0019] The mass spectrometer installed above the converter boiler is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com