Heat treatment method for low-carbon manganese steel tubes

A heat treatment method and technology for carbon-manganese steel, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems that the performance of steel pipes cannot be fully satisfied, and achieve the effects of high performance qualification rate, small performance fluctuation range and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

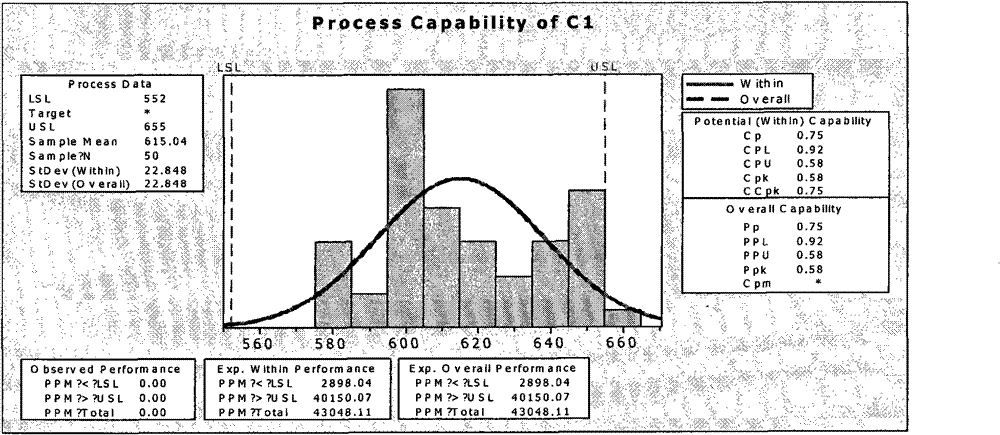

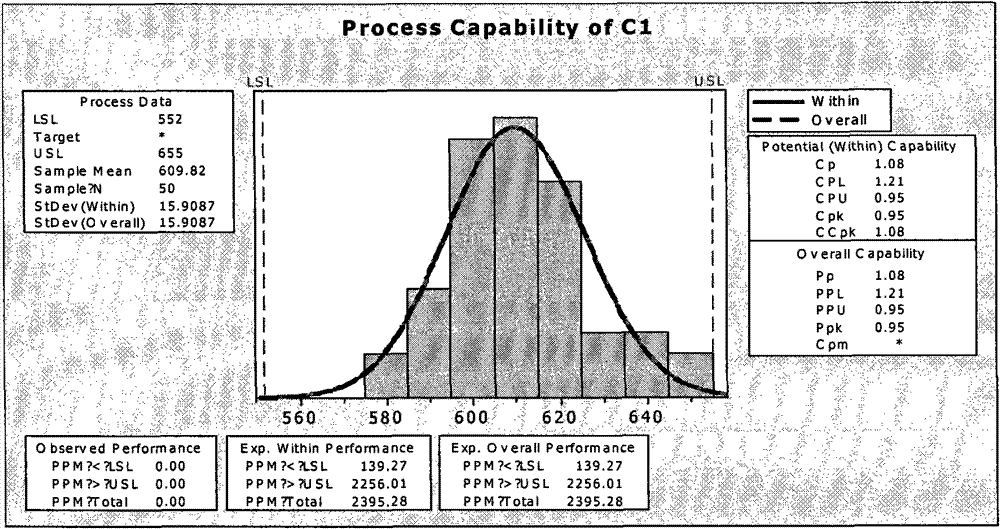

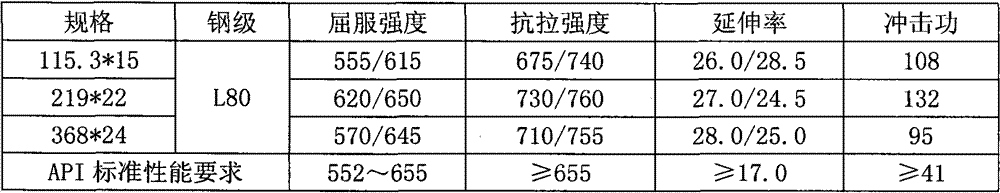

[0020] Embodiment 1. In this embodiment, low-carbon manganese steel is used to produce oil well pipes, the specification is 368*24, and the steel grade is L80. The composition of low-carbon manganese steel oil well pipes is expressed in mass %, specifically: Si: 0.10~0.50, Mn: 1.30~1.50, P: ≤0.035, S: ≤0.035, V: 0.08~0.18, Al: 0.01~0.06, and the rest are Fe, trace alloy V, Cr and unavoidable impurities.

[0021] For steel pipes with the above composition, through the statistical analysis of heat treatment test and production data, within the scope of Class III steel pipes, the steel pipes with a specification of 273*22.5 are relatively stable, and the steel pipes with a specification of 273*22.5 are used as a benchmark. Mi heavy craft. The meter weight of the steel pipe is: M=(273-22.5)×22.5×0.02466Kg=139Kg; the heat treatment process is: quenching temperature 915 degrees, heat preservation for 30 minutes, water quenching after the furnace, the cooling water volume of water qu...

Embodiment 2

[0023] Embodiment 2. In this embodiment, low-carbon manganese steel is used to produce oil well pipes, the specification is 219*22, and the steel grade is L80. The composition of low-carbon manganese steel oil well pipes is expressed in mass%, specifically: Si: 0.10~0.50, Mn: 1.30~1.50, P: ≤0.035, S: ≤0.035, V: 0.08~0.18, Al: 0.01~0.06, and the rest are Fe, trace alloy V, Cr and unavoidable impurities.

[0024] For steel pipes with the above composition, through statistical analysis of heat treatment tests and production data, within the scope of Class II steel pipes, the steel pipes with a specification of 196*17 are relatively stable in process, and the steel pipes with a specification of 196*17 are used as a benchmark Mi heavy craft. The meter weight of the steel pipe is: M=(196-17)×17×0.02466Kg=75Kg; the heat treatment process is: quenching temperature 920 degrees, heat preservation for 30 minutes, water quenching after the furnace, the cooling water volume of water quench...

Embodiment 3

[0026] Embodiment 3. In this embodiment, low-carbon manganese steel is used to produce oil well pipes, the specification is 115.3*15.5, and the steel grade is L80. The composition of low-carbon manganese steel oil well pipes is expressed in mass %, specifically: Si: 0.10~0.50, Mn: 1.30~1.50, P: ≤0.035, S: ≤0.035, V: 0.08~0.18, Al: 0.01~0.06, and the rest are Fe, trace alloy V, Cr and unavoidable impurities.

[0027]For the steel pipes with the above composition, through the statistical analysis of heat treatment test and production data, within the scope of Class I steel pipes, the steel pipes with a specification of 89*12.5 are more stable, and the steel pipes with a specification of 89*12.5 are used as a benchmark Mi heavy craft. The meter weight of the steel pipe is: M=(89-12.5)×12.5×0.02466 Kg=23.5Kg; the heat treatment process is: quenching temperature 915 degrees, heat preservation for 30 minutes, water quenching after the furnace, the cooling water volume of water quenc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com