Precision stamping cold-rolled steel plate for automobile seat adjuster gear plate and manufacturing method thereof

A car seat and precision stamping technology, which is applied in the field of cold-rolled steel plates, can solve the problems of being unsuitable for high-speed precision stamping, low dimensional accuracy, and low spheroidization rate, and achieve shortened annealing and holding time, good surface quality, and good uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

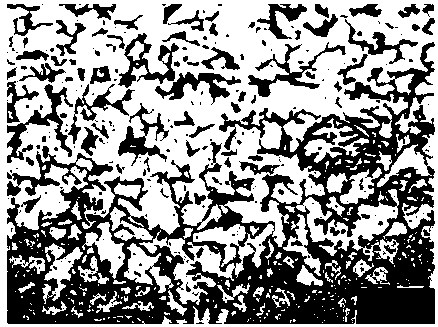

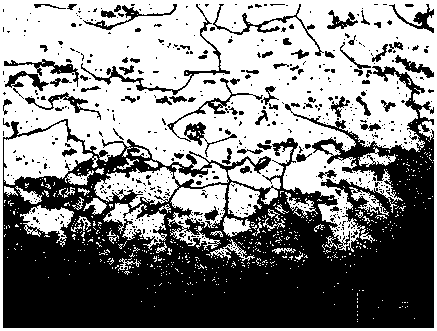

Image

Examples

Embodiment Construction

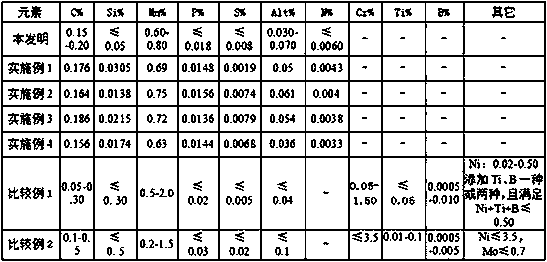

[0047] The present invention will be further described below in conjunction with Examples 1-4 and Comparative Example 1—disclosed in Chinese Patent Application No. 200910196007.4, and Comparative Example 2—disclosed in Chinese Patent Application No. 200780004015.3, as shown in Tables 1 to 4.

[0048] Table 1 The chemical composition of the present invention (% by weight), the balance is Fe and unavoidable impurities.

[0049]

[0050] According to the requirements of the material composition design of the present invention, pre-desulfurization of molten iron is adopted, top-bottom compound blowing of converter, Ar blowing station (or LF furnace temperature rise) Bottom blowing Ar ensures the stirring time is more than 8 minutes, RH furnace carries out composition fine-tuning, vacuum cycle degassing Treatment, to ensure that the RH pure degassing time is greater than 8 minutes, Ar protection casting is blown throughout the process, and cut into length continuous casting slabs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com