A kind of production method of round steel for ultra-high strength bolts

A production method and ultra-high-strength technology, applied in the direction of improving process efficiency, can solve the problems that are not involved, and achieve the effects of improving density and composition segregation, refining grains, and reducing delayed fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

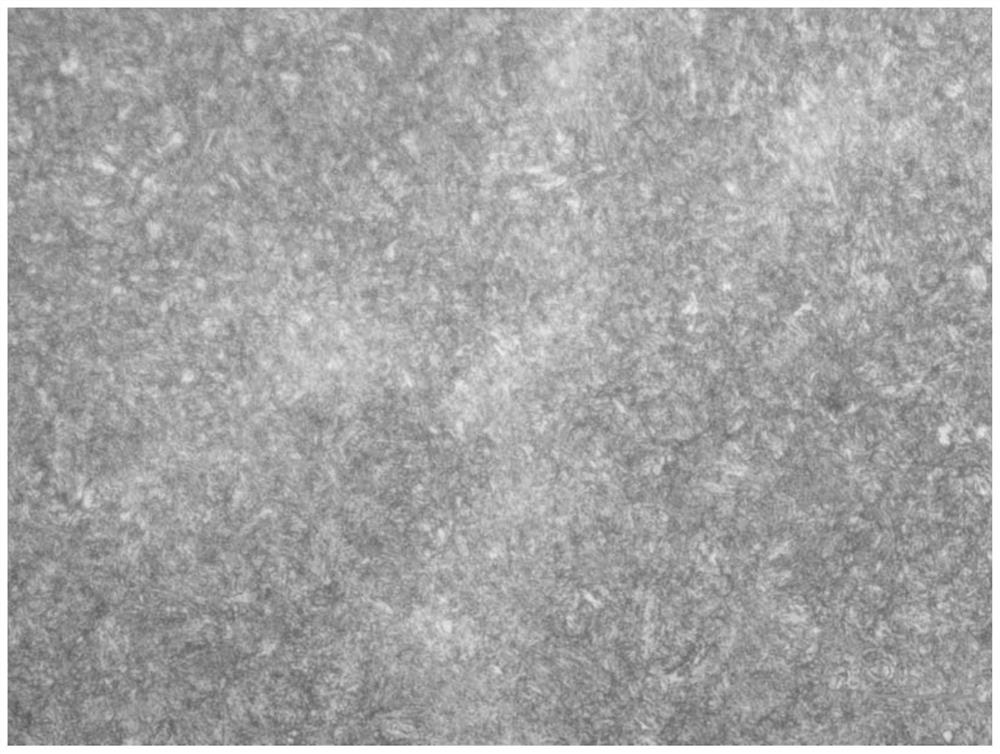

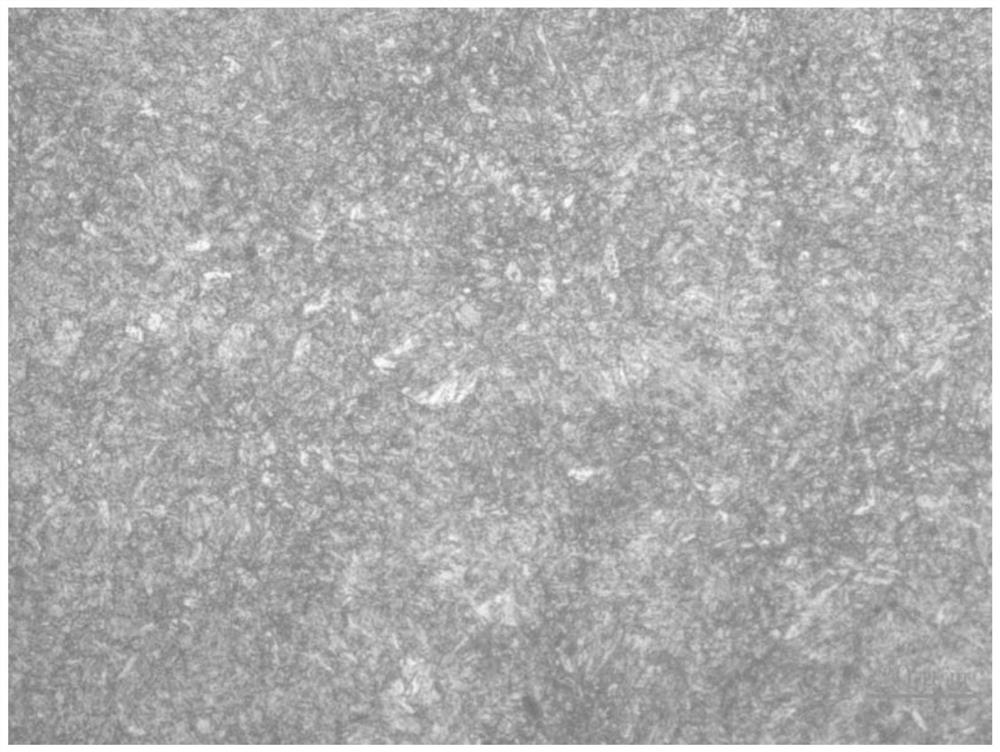

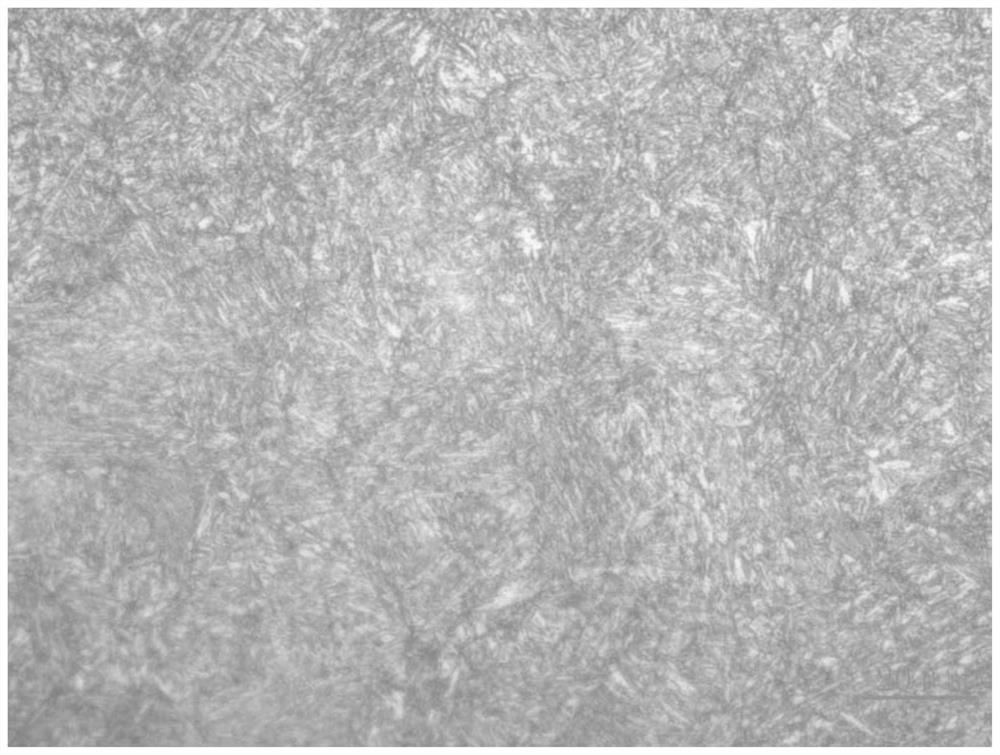

Image

Examples

Embodiment 1

[0030]The properties of the Φ31mm rolled products produced by continuous casting rectangular billets with a section of 150mm×150mm all meet the technical requirements. The specific process method is as follows:

[0031] (1) Using 45t molten iron and steel scrap as raw materials, using ultra-high power eccentric bottom electric furnace for smelting: in the electric furnace smelting process, use 50% molten iron + scrap steel raw material ratio to explore the electric furnace smelting, control the C content wt≥0.06 in tapping %, P content wt≤0.010% in tapping; add SiCaBaAl 1.0kg / t and steel core aluminum 1.5kg / t for strong deoxidation when tapping 15t, then add ferroalloy material, recarburizer, and slag into the ladle, and use Strong argon stirring to uniform temperature and composition, and promote the deoxidation product to float;

[0032] (2) Refining materials with LF refining furnace; the refining furnace uses calcium carbide and silicon carbide to diffuse and deoxidize in...

Embodiment 2

[0045] The properties of the Φ34mm rolled products produced by continuous casting rectangular billets with a cross-section of 150mm×150mm all meet the technical requirements. The specific process method is as follows:

[0046] (1) Using 45t of high-quality molten iron as the main raw material, using an ultra-high-power eccentric bottom-type electric furnace for smelting: in the electric furnace smelting process, molten iron is used for electric furnace smelting, the tapping control C content wt is 0.08%, and the tapping P content wt≤0.010% ; Add SiCaBaAl 1.2kg / t and steel core aluminum 2.0kg / t for strong deoxidation when tapping 18t, then add ferroalloy material, recarburizer, and slag into the ladle, and use argon gas to stir strongly in the later stage of tapping to uniform temperature and composition , and promote the deoxygenation product to float;

[0047] (2) Refining the material with LF refining furnace; in the early stage of the refining furnace, calcium carbide and ...

Embodiment 3

[0059] The properties of the Φ38mm rolled products produced by continuous casting rectangular billets with a section of 150mm×150mm all meet the technical requirements. The specific process method is as follows:

[0060] (1) Using molten iron and steel scrap as raw materials, using ultra-high power eccentric bottom electric furnace for smelting: in the electric furnace smelting process, the raw material ratio of 70% molten iron + scrap steel is used to explore the electric furnace smelting, and the tapping control C content wt ≥ 0.06% , P content wt≤0.010% in tapping; add SiCaBaAl 1.0~1.5kg / t and steel core aluminum 1.5~2.5kg / t for strong deoxidation when tapping 15~20t, ferroalloy material, recarburizer and slag are then added to the ladle In the later stage of tapping, strong argon stirring is used to uniform temperature and composition, and to promote the deoxidation product to float;

[0061] (2) Refining the material with LF refining furnace; in the early stage of refini...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com