System for realizing automatic and continuous cleanness detection of multiple sample points

A technology of sampling points and cleanliness, applied in the heat treatment of cold-rolled metal strips, home appliance panel production, and mid-to-high-end automobiles, to increase the difficulty of operation, increase the probability of misjudgment, and improve the control level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1. A system for realizing automatic and continuous cleanliness detection of multiple sampling points

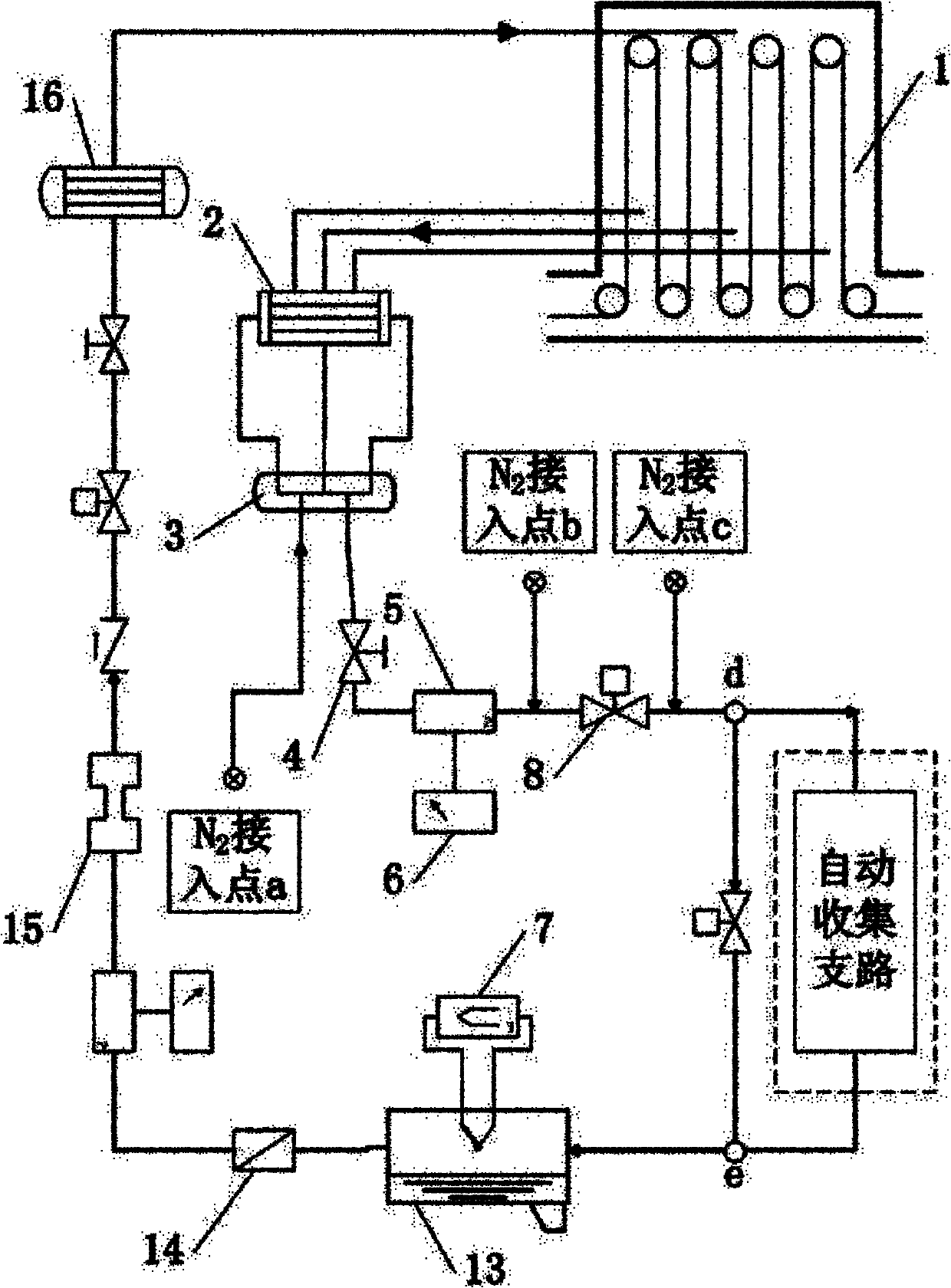

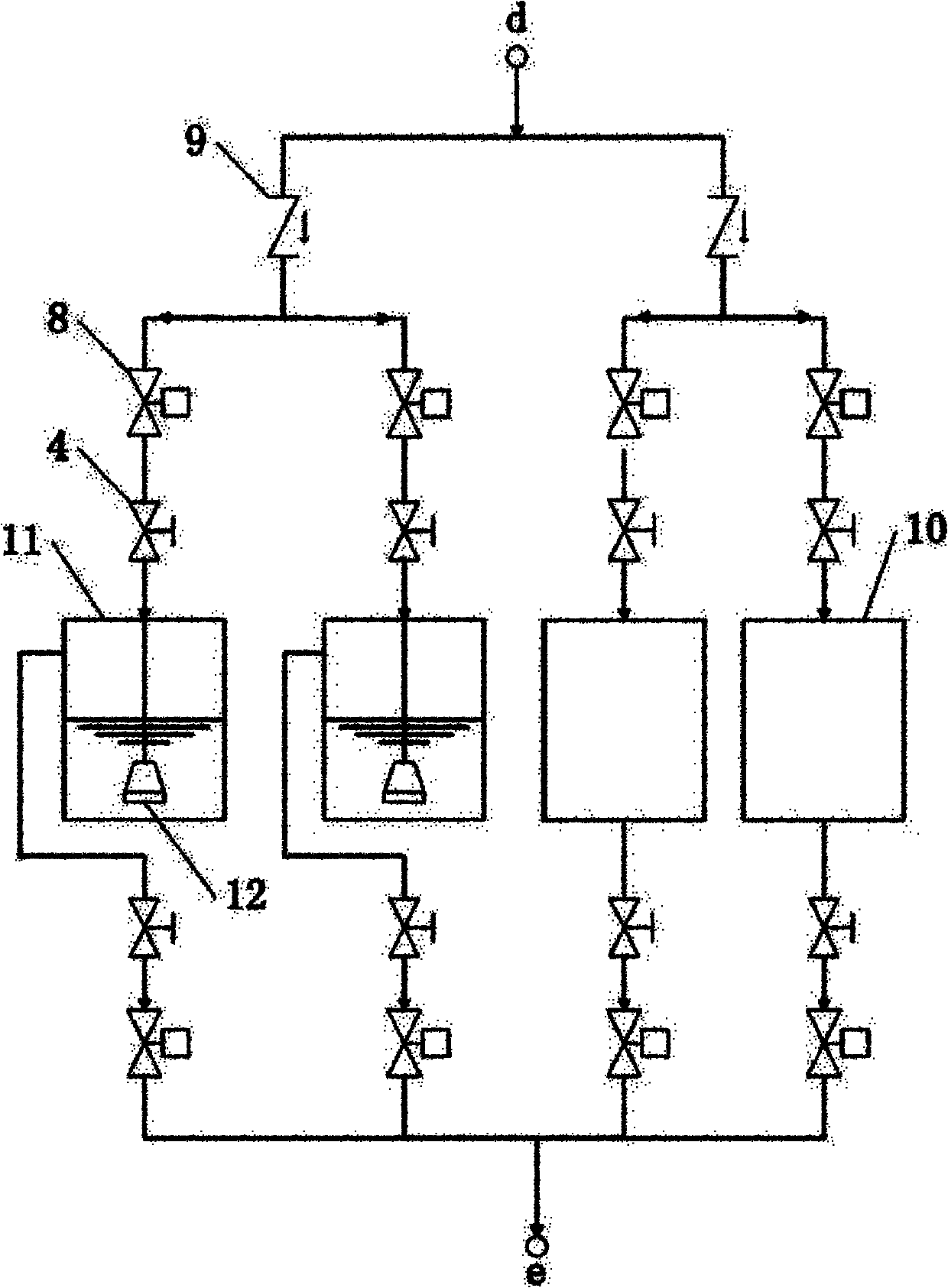

[0021] A system for automatic and continuous cleanliness detection of multiple sampling points (referred to as the detection system), its structure is as follows figure 1 Shown: It is mainly composed of three parts: the furnace gas sampling supervisor, the continuous automatic collection branch of furnace gas pollutants, and the metering and gas return supervisor.

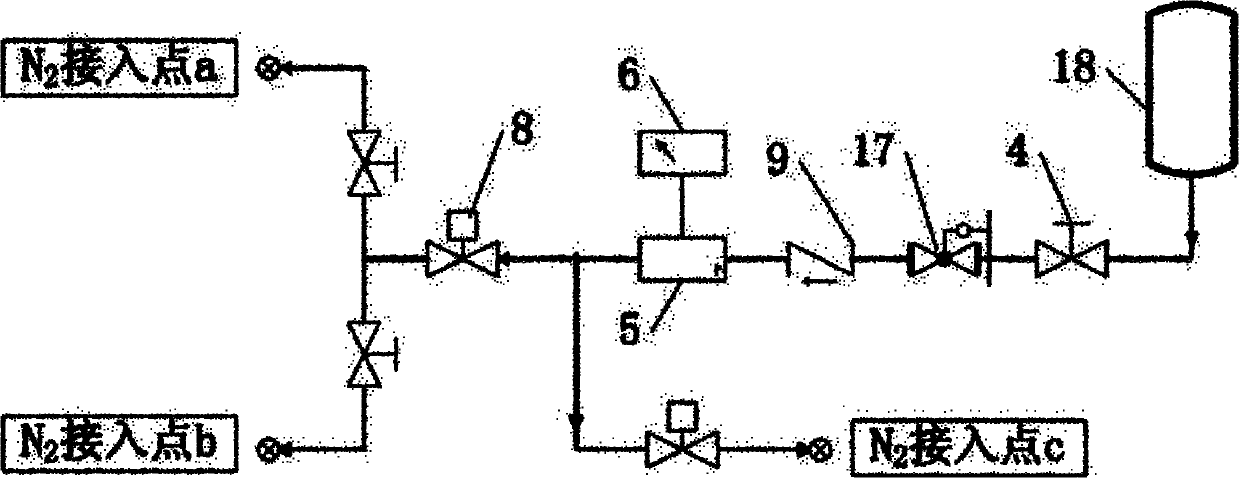

[0022] The first part is the furnace gas sampling supervisor, such as figure 1 As shown: along the airflow direction, it is composed of sampling gas cooler 2, gas distributor 3, first manual switch valve 4, pressure detection instrument 5, pressure signal conversion display instrument 6, and first automatic switch valve 8, followed by gas pollution The access point d of the object collector branch. In addition, there are three purge nitrogen access points a, b, and c, which are used for the s...

Embodiment 2

[0028] Embodiment 2. Realize the application of the automatic continuous cleanliness detection system of multiple sampling points

[0029] The detection system provided by the present invention can be used in the detection of the cleanliness of the atmosphere at multiple sampling points in the continuous annealing furnace in the field of medium and high-end automobile or household appliance panel production. The detection system is based on the following detection methods, specifically: use a sampling metering pump to pump out the gas in the furnace chamber of the annealing furnace, control the automatic switch valve in the main circuit to select the collector, and make the furnace gas pass through the currently selected collector according to the set flow rate , various particles in the furnace gas are blocked in the collector. The controller sorts each sampling point and the collector correspondingly according to the setting, and according to the sorting, opens the channel c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com