Rotary pipeline dredging cleaner

A rotary type and cleaning device technology is applied in the field of sewer pipeline dredging equipment, which can solve the problems of inability to dredging and cleaning sludge pipelines, manual waste, affecting work efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

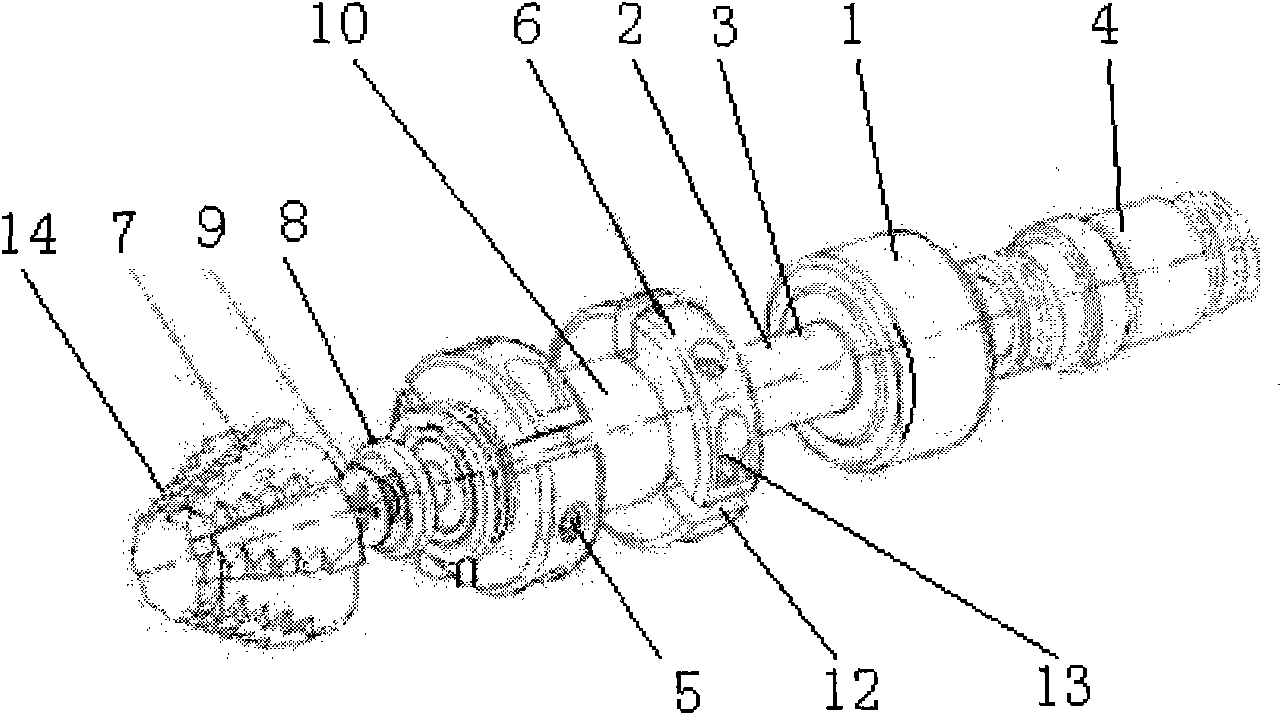

[0017] Such as figure 1 As shown, the present invention includes a pipe shaft 2 provided with a water jet seat 1, the pipe shaft 2 is provided with a water outlet 3, and the end of the pipe shaft 2 water jet seat 1 is provided with a connecting head 4 with a high-pressure rubber hose (the water jet seat It is threaded with the connecting head). It also includes a rotating sleeve 6 provided with a water injection hole 5 and a punching head 7, and the rotating sleeve 6 is movably connected to the pipe shaft 2 (limited by tightening the limit pad 8 and the bolt 9). The inner peripheral surface of the rotating sleeve 6 is provided with a ring of water inlet grooves (not shown in the figure), and the water inlet grooves are matched and communicated with the water outlet holes 3 on the pipe shaft 2 . The piercing head 7 is threadedly connected to the rotary sleeve 6 .

[0018] Such as figure 1 , 2 As shown in , 3, two rotating sleeves 6 are provided, and the two are connected by...

Embodiment 2

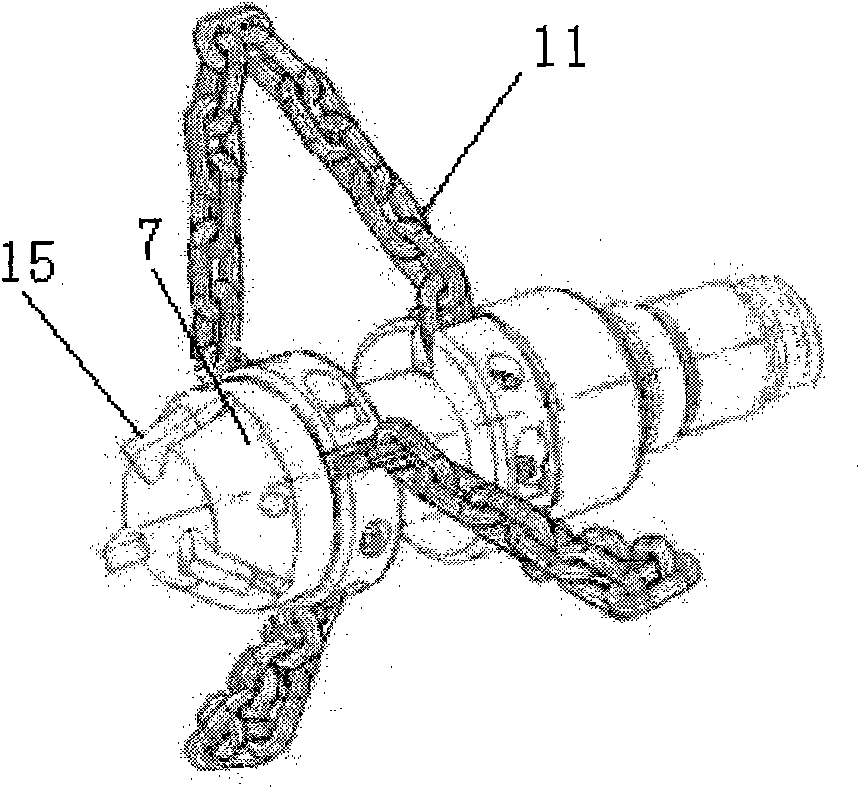

[0024] Such as figure 2 As shown, the piercing head 7 is a circular truncated body, and blades 15 are equally divided on the peripheral surface. All the other implementations are as in Example 1.

Embodiment 3

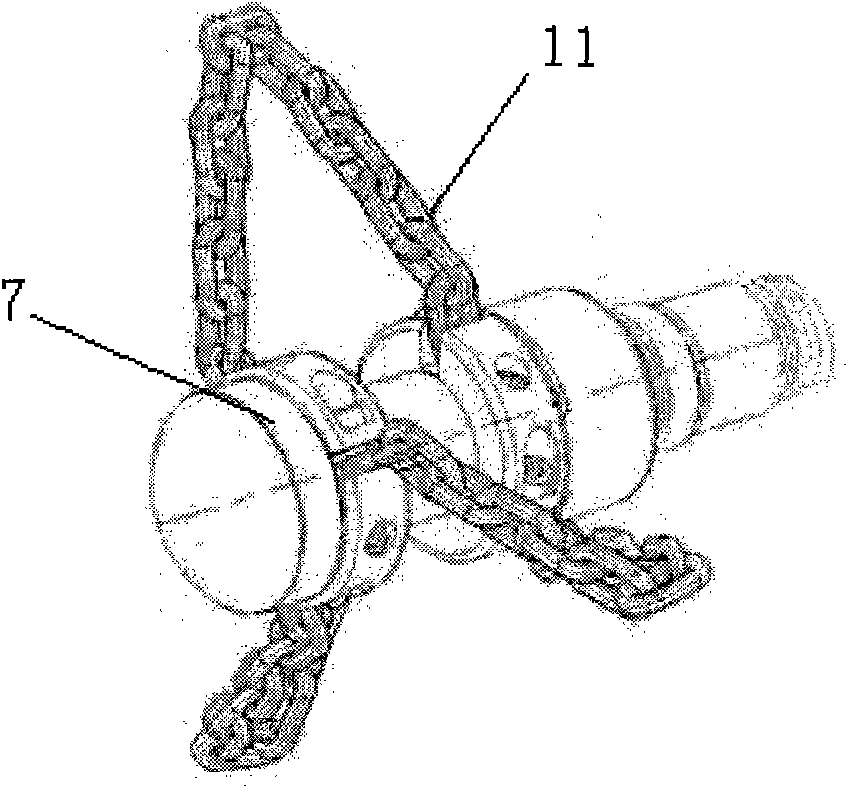

[0026] Such as image 3 As shown, the piercing head 7 is a circular frustum, and the peripheral surface is a smooth surface. All the other implementations are as in Example 1.

[0027] The piercing heads 7 of the three structures in Embodiments 1, 2, and 3 can be assembled as required.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com