Polytrimethylene carbonate modified graphene oxide enhanced polyethylene fishing net

A methyl carbonate, stone oxide technology, applied in the direction of single-component polyolefin rayon, chemical characteristics of fibers, textiles and papermaking, etc., to achieve improved breaking strength and nodular strength, improved physical and mechanical properties, and improved bonding strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

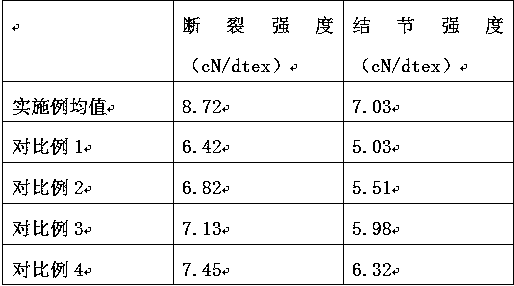

Examples

Embodiment 1

[0019] A polytrimethylene carbonate-modified graphene oxide reinforced polyethylene fishing net contains 3.2% by mass of polytrimethylene carbonate-modified graphene oxide.

[0020] Further, the preparation method of the polytrimethylene carbonate modified graphene oxide comprises the following steps:

[0021] (1) Evenly disperse graphene into deionized water to prepare a graphene dispersion;

[0022] (2) heating the above graphene dispersion, then adding sodium hypochlorite with 1.2% of graphene dispersion mass, stirring at 120r / min for 2 hours, then adding 3.5% graphene dispersion mass of aniline and 0.32% of dichloride. Lithium oxalate borate was heated to 80°C under an inert gas atmosphere, stirred at a speed of 500 r / min for 15 minutes, then added potassium persulfate with 0.1% graphene mass, continued to keep stirring for 3 hours, then filtered the solids, and used removing Ionized water cleans the solid to neutrality, and oven drys to constant weight to obtain a graphe...

Embodiment 2

[0032] A polytrimethylene carbonate-modified graphene oxide reinforced polyethylene fishing net contains 3.5% by mass of polytrimethylene carbonate-modified graphene oxide.

[0033] Further, the preparation method of the polytrimethylene carbonate modified graphene oxide comprises the following steps:

[0034] (1) Evenly disperse graphene into deionized water to prepare a graphene dispersion;

[0035] (2) heating the above graphene dispersion, then adding sodium hypochlorite with 1.2% of graphene dispersion mass, stirring at 120r / min for 2 hours, then adding 3.5% graphene dispersion mass of aniline and 0.32% of dichloride. Lithium oxalate borate was heated to 80°C under an inert gas atmosphere, stirred at a speed of 500 r / min for 15 minutes, then added potassium persulfate with 0.1% graphene mass, continued to keep stirring for 3 hours, then filtered the solids, and used removing Ionized water cleans the solid to neutrality, and oven drys to constant weight to obtain a graphe...

Embodiment 3

[0045] A polytrimethylene carbonate modified graphene oxide reinforced polyethylene fishing net contains 3.4% of its mass of polytrimethylene carbonate modified graphene oxide.

[0046] Further, the preparation method of the polytrimethylene carbonate modified graphene oxide comprises the following steps:

[0047] (1) Evenly disperse graphene into deionized water to prepare a graphene dispersion;

[0048](2) Heat the above-mentioned graphene dispersion, then add sodium hypochlorite with a mass of 1.2% of the mass of the dispersion of graphene, stir at a speed of 120r / min for 2 hours, and then add aniline of 3.5% of the mass of the dispersion of graphene and 0.32% dichloride Lithium oxalate borate, in an inert gas atmosphere, heated to 80°C, stirred at a speed of 500r / min for 15min, then added potassium persulfate with 0.1% graphene mass, continued to keep stirring for 3 hours, and then filtered the solids, using Ionized water is used to clean the solid matter to neutrality, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com