Eccentric push circumferentially-distributed plunger pump

A distributed, plunger pump technology, applied in the direction of variable displacement pump components, pumps, multi-cylinder pumps, etc., can solve the problems of too many consumable materials, troublesome crankshaft, chain processing, noise and other problems, to extend the service life, resist the The effect of good grinding performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

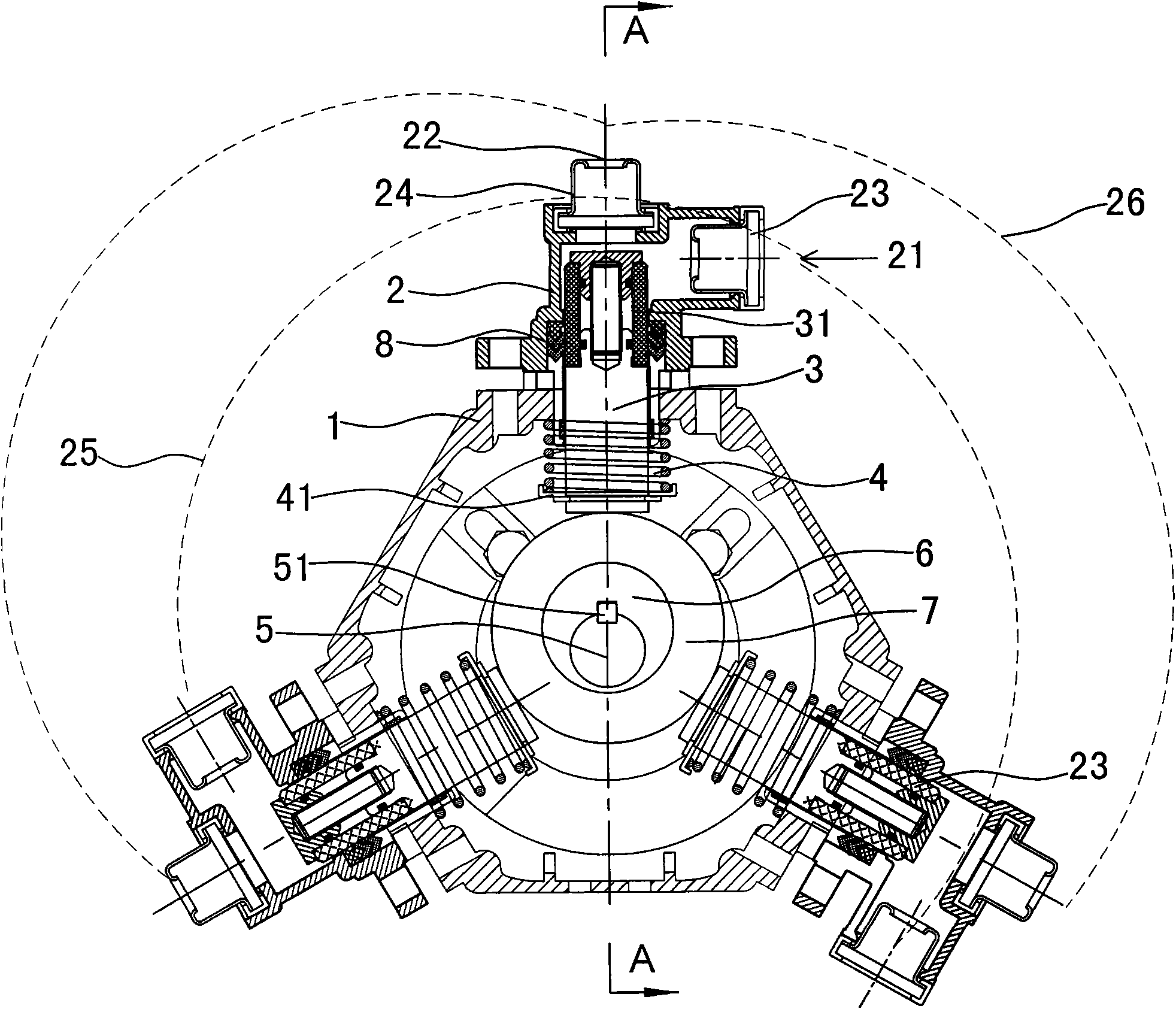

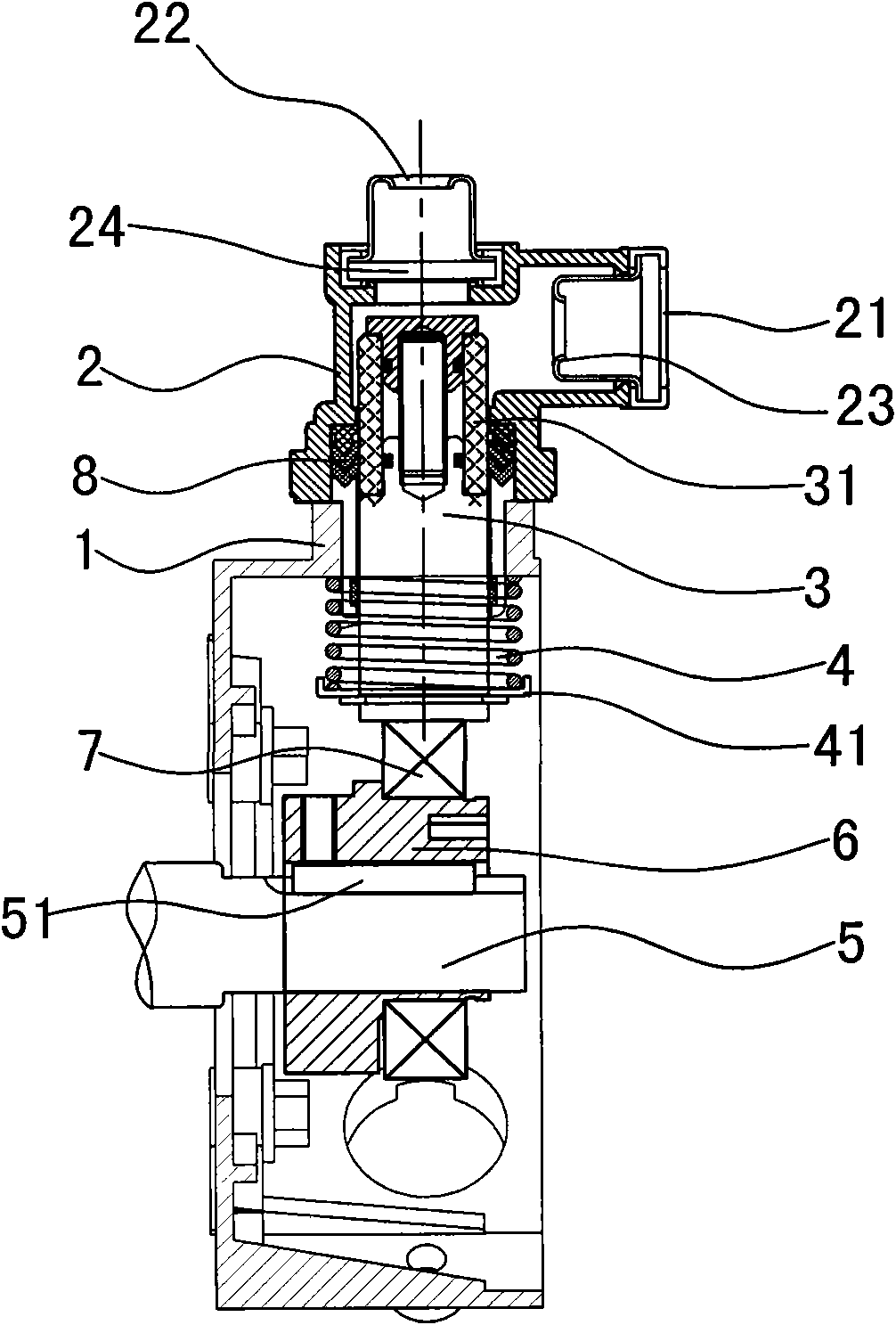

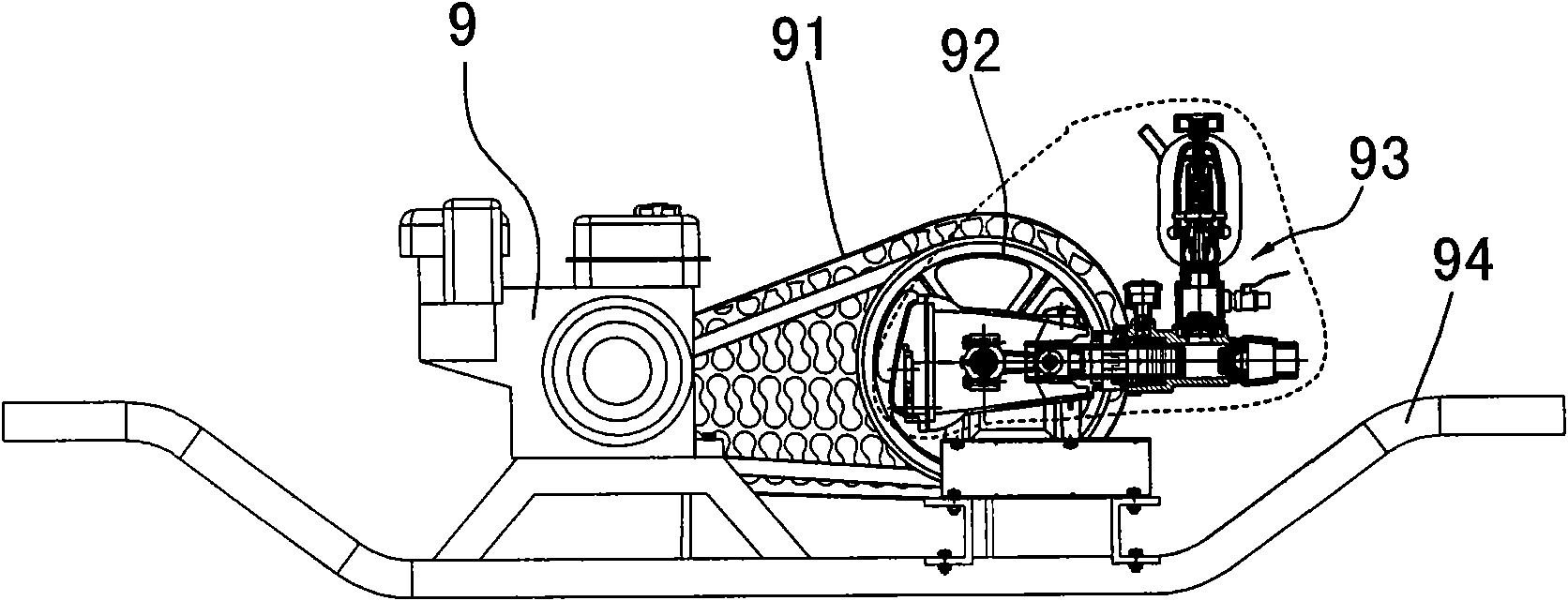

[0010] The eccentrically propelled circumferential distributed plunger pump of the present invention, as Figure 1-Figure 2 As shown, it includes a box body 1, a plunger cylinder 2, a plunger 3, an output shaft 5, and a plunger pushing mechanism installed on the output shaft 5. The plunger cylinder 2 is installed on the box body 1, and the plunger 3 and the plunger The cylinder cavity is matched, and it is characterized in that the plunger pushing mechanism includes an eccentric wheel 6 installed on the output shaft 5, the eccentric wheel 6 is in contact with the head of the plunger, and there is a return spring 4 outside the plunger, and the return spring 4 Both ends are in contact with the spring holder 41 and the casing 1 . The main structure of this technical solution includes box 1, plunger cylinder 2, plunger 3 and output shaft 5, etc., plunger cylinder 2 is installed on the box body 1, plunger 3 is installed in the plunger cylinder cavity, plunger 3 Driven by the prope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com