LED explosion-proof lamp

A technology of LED explosion-proof lamp and LED light source, which is applied in the direction of lampshade, damage prevention measures of lighting device, cooling/heating device of lighting device, etc., which can solve the problems of large damage risk of lamp beads, short irradiation distance, poor heat dissipation effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

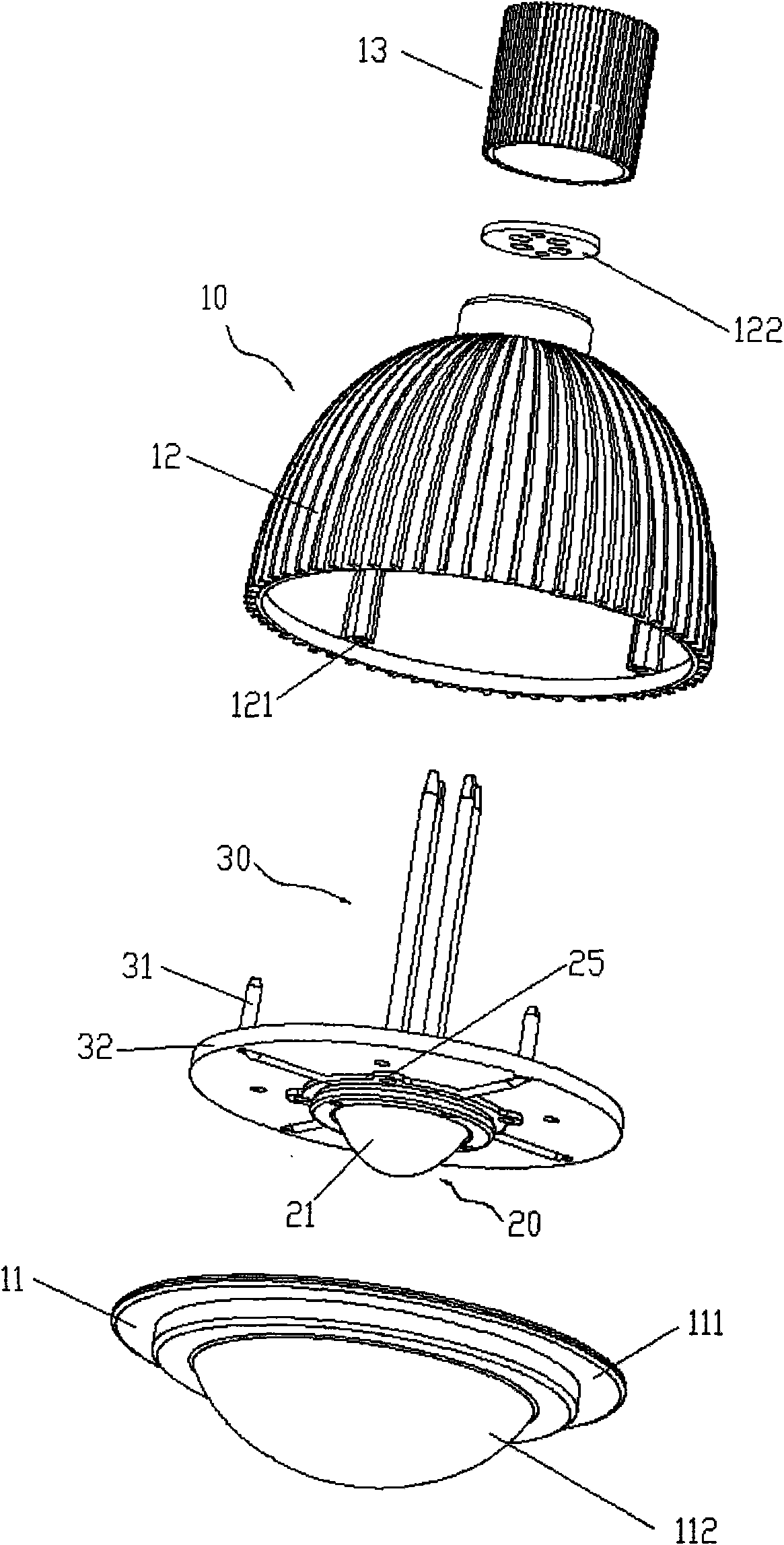

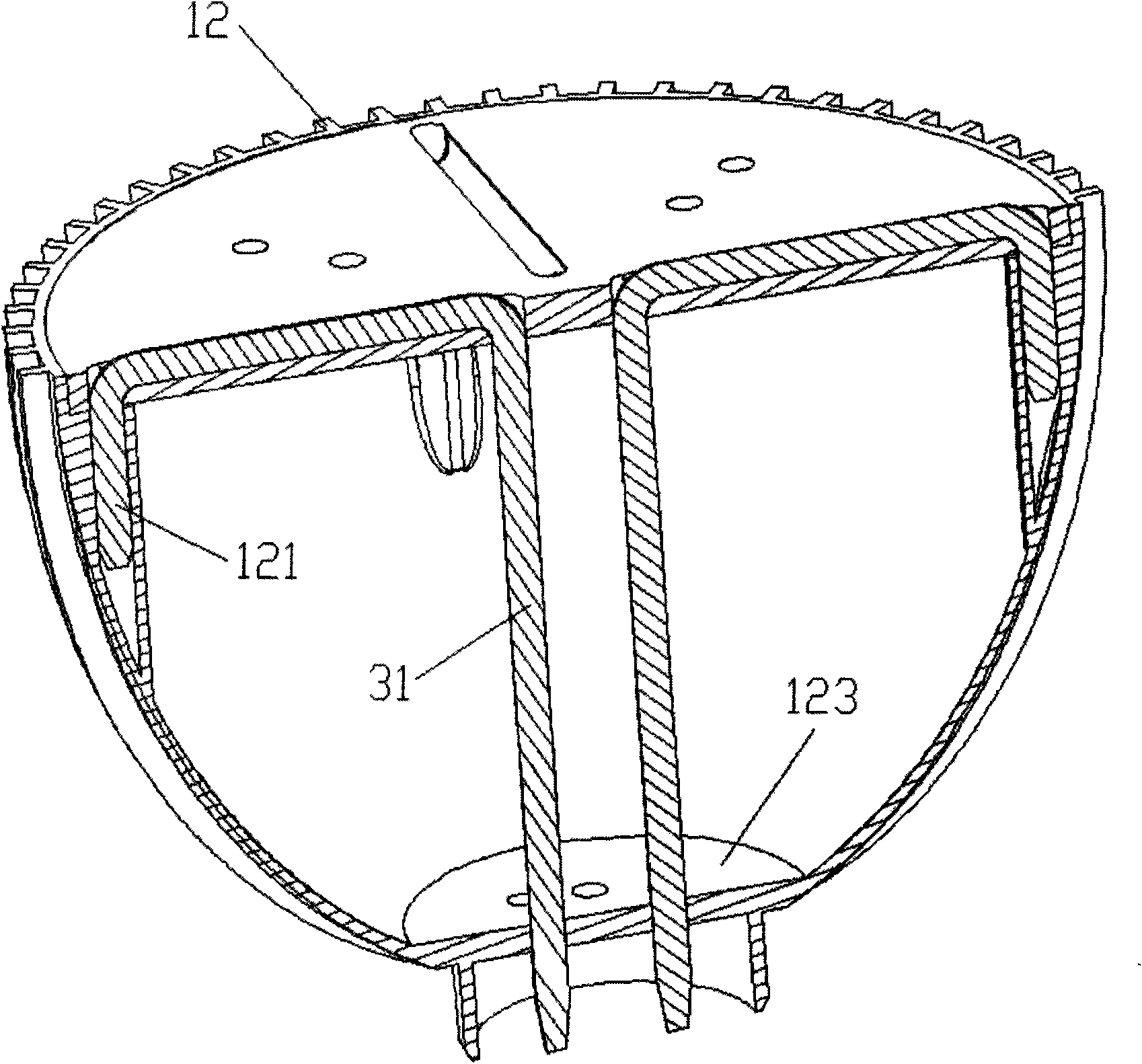

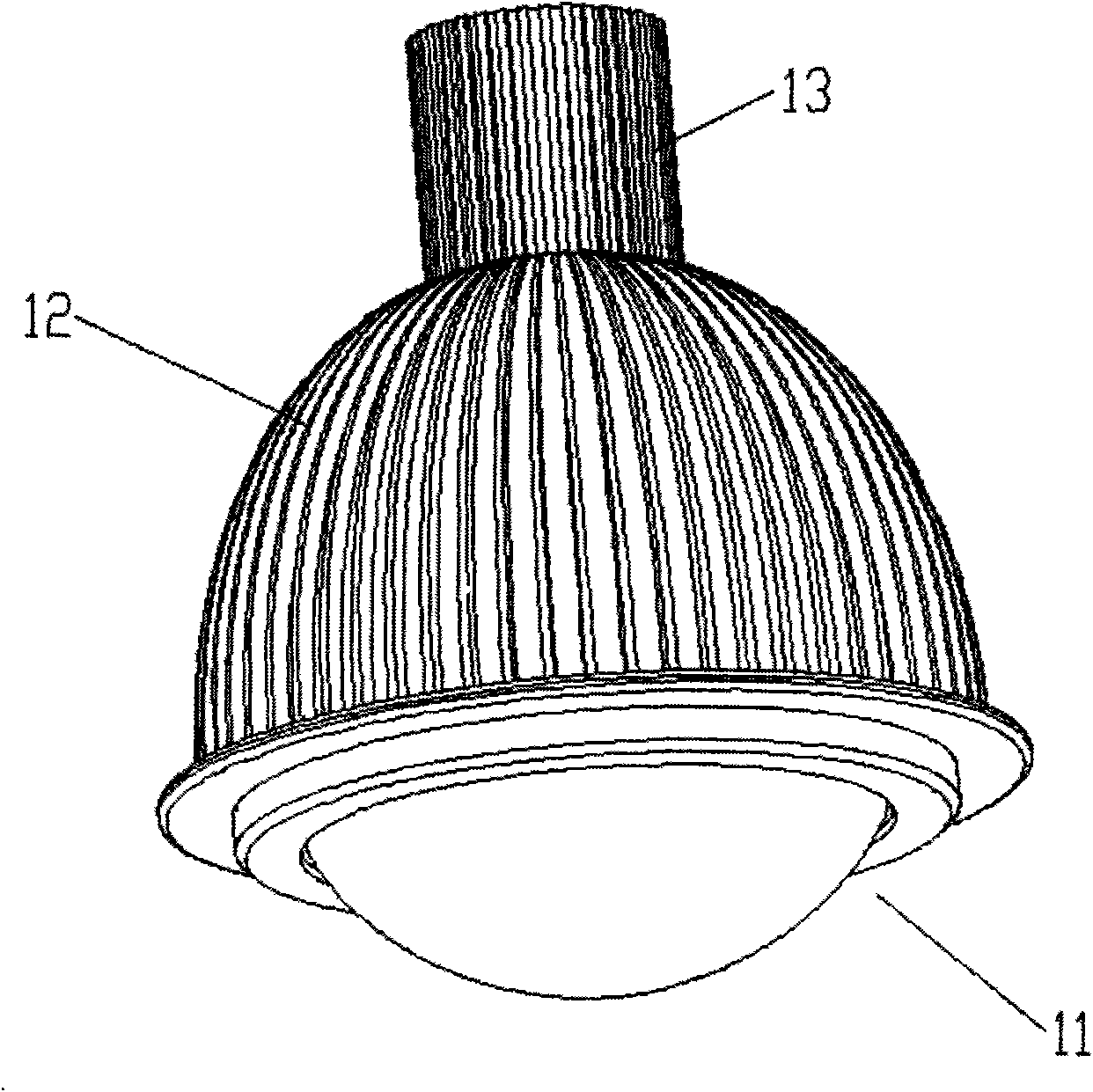

[0013] see figure 1 , 2 , 3, the LED explosion-proof lamp of the present invention mainly includes a lamp housing 10, a multi-chip packaged LED light source module 20 and an LED heat sink 30. The lamp housing 10 is used to accommodate the LED light source module 20 and the LED The heat dissipation device 30 is composed of a lampshade 11, a lamp body 12 and a bottom cover 13. The lampshade 11 is a light-transmitting cover-shaped body, which is located on one side of the lamp body 12, and the lamp body 12 The other non-open side is connected with a bottom cover 13, and the bottom cover 13 is a cover-shaped body that matches the shape of the lamp body 12, and the lamp body 12 is open on one side and has an accommodating space inside. The conical metal shell has a plurality of cylindrical jacks 121 on its inner wall for inserting and fixing one end of the heat pipe 31, and there are a plurality of circular holes 123 on one end of the lamp body 12 without opening, and the other en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com