Silicon-based active organic light emitting diode (OLED) display pixel circuit

A technology of light-emitting diodes and pixel circuits, applied to static indicators, instruments, etc., can solve problems such as gate-source voltage changes, OLED drive current glitches, production cost effects, etc., to achieve the effect of ensuring control and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

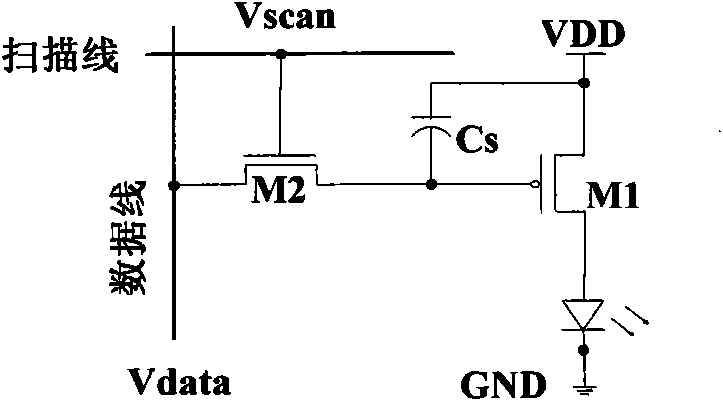

Embodiment 1

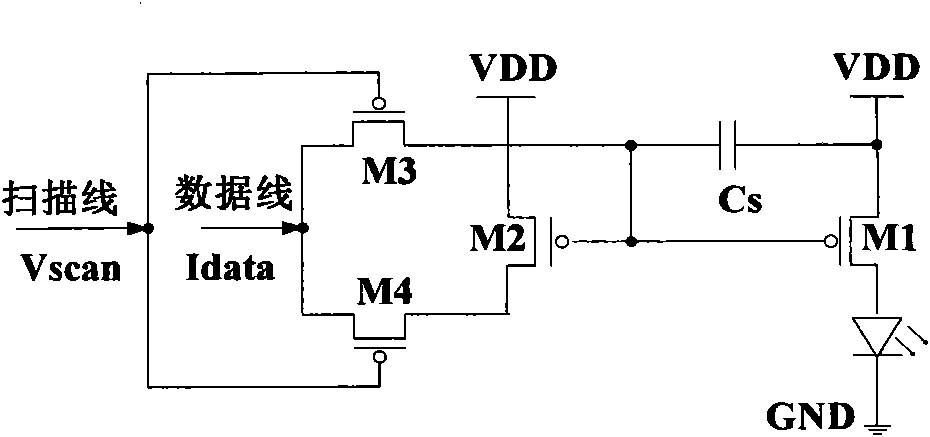

[0044] to improve Figure 4 The performance of the classic 2T1C circuit in AC application, the present invention proposes an improved 3T1C (3 transistors and a storage capacitor) voltage control pixel circuit, such as Figure 6 shown. and Figure 4 Compared with the circuit, this circuit only adds a switch tube M3 between the drive tube M1 and the OLED, and its gate is connected to the common cathode voltage V COM connected. The driving timing of the circuit is shown in the figure. Also during programming, Vscan and V COM is high level, the switch M2 is turned on, the storage capacitor is charged and the data voltage Vdata is stored. At this time, the OLED is in the reverse bias state, M1 and M3 are turned off, and no current flows; then enters the light-emitting stage, Vscan and V COM Change to low level, M2 is turned off, switch M3 is turned on, the data voltage Vdata stored on the storage capacitor makes M1 turn on, the OLED is forward-biased, and the driving current pr...

Embodiment 2、3T1

[0050] Embodiment 2, Further improvement scheme of 3T1C pixel circuit

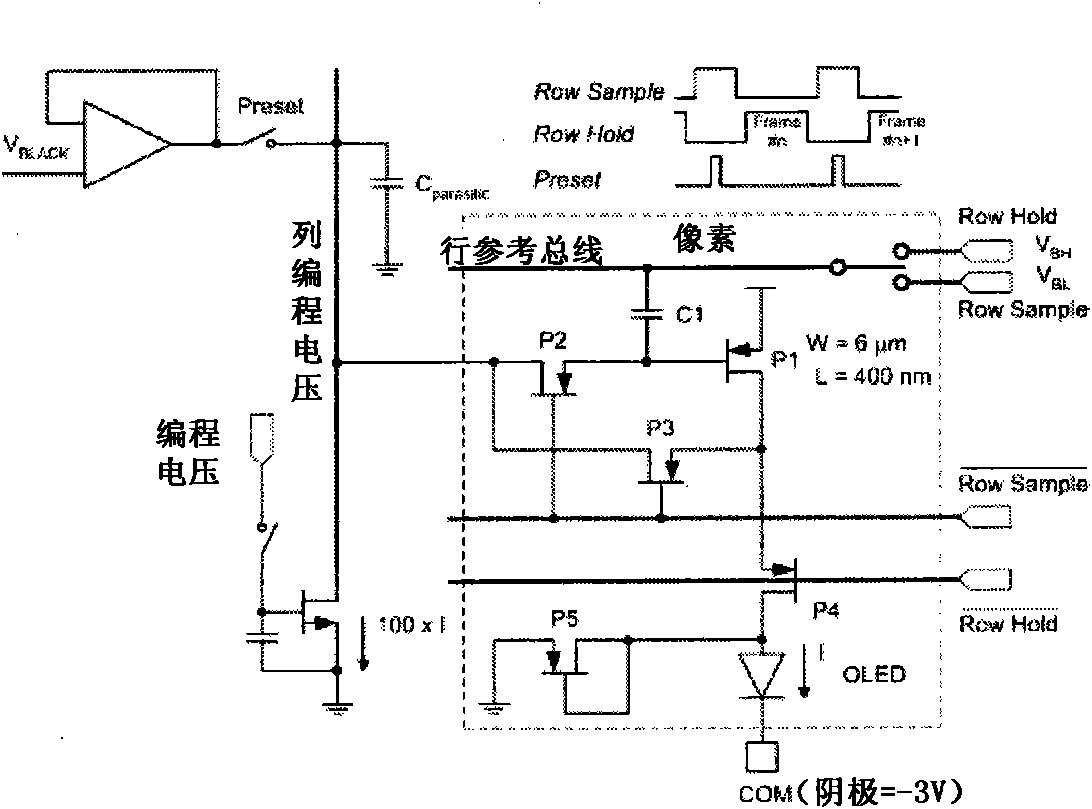

[0051] Due to the small size of silicon-based AMOLED pixels, the driving current of the corresponding OLED area is very small, for example, the OLED current density is 40mA / cm 2 , then the drive current required for a 20μm×20μm pixel area is 20μm×20μm×40mA / cm 2 , ie 0.16µA. Even if the smallest size MOS tube is used, its current will still exceed the OLED current, unless the length of the MOS channel is lengthened as much as possible, which in turn contradicts the requirement of a smaller pixel area of the silicon-based AMOLED. Therefore, the present invention proposes another pixel circuit to further reduce the driving current on the basis of the previous circuit. The circuit structure and working sequence are as follows: Figure 10 shown. In the figure, the storage capacitor is no longer fixedly connected to VDD, but is connected to the reference voltage VCH or VCL through a selection switch, where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com