Method for forming through hole at bottom of groove

A technology of grooves and substrates, which is applied in the manufacture of electrical components, semiconductor/solid-state devices, circuits, etc., can solve the problems of inability to form qualified patterned photoresist layer through holes, insufficient exposure, and inability to be reliably removed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

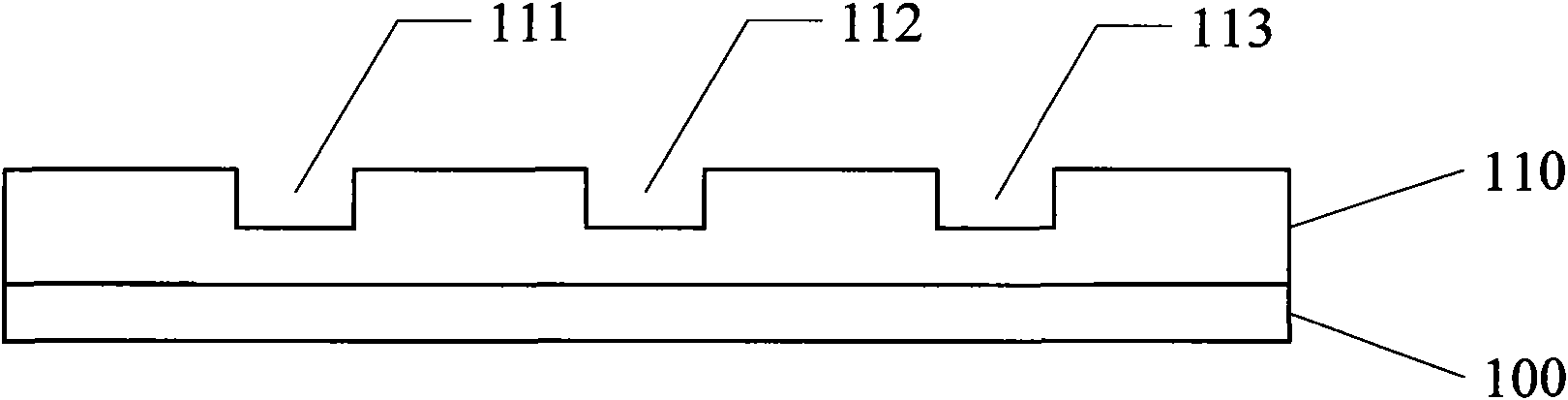

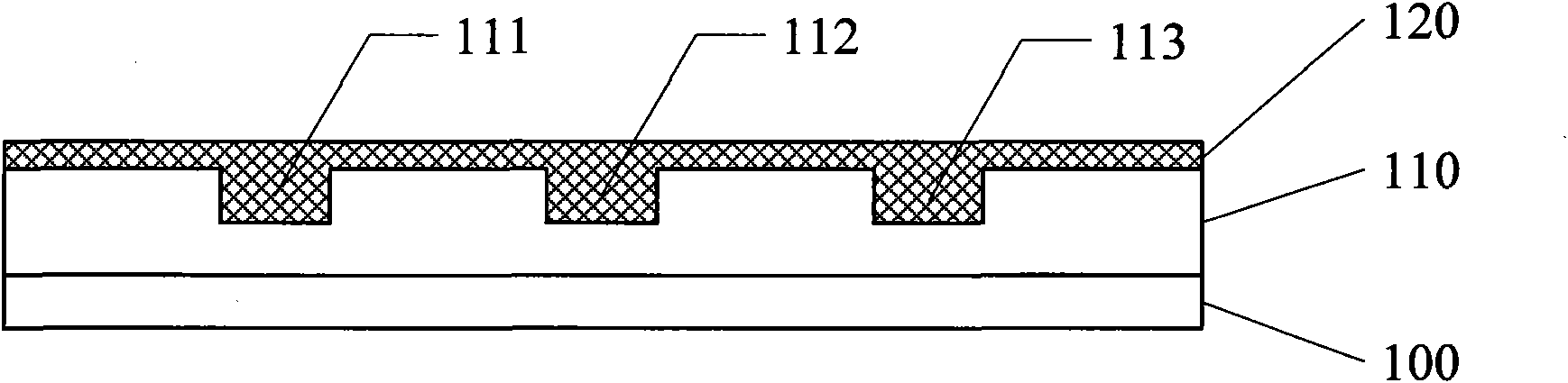

[0025] The specific implementation of the method for forming a through hole at the bottom of the trench provided by the present invention will be described in detail below with reference to the accompanying drawings.

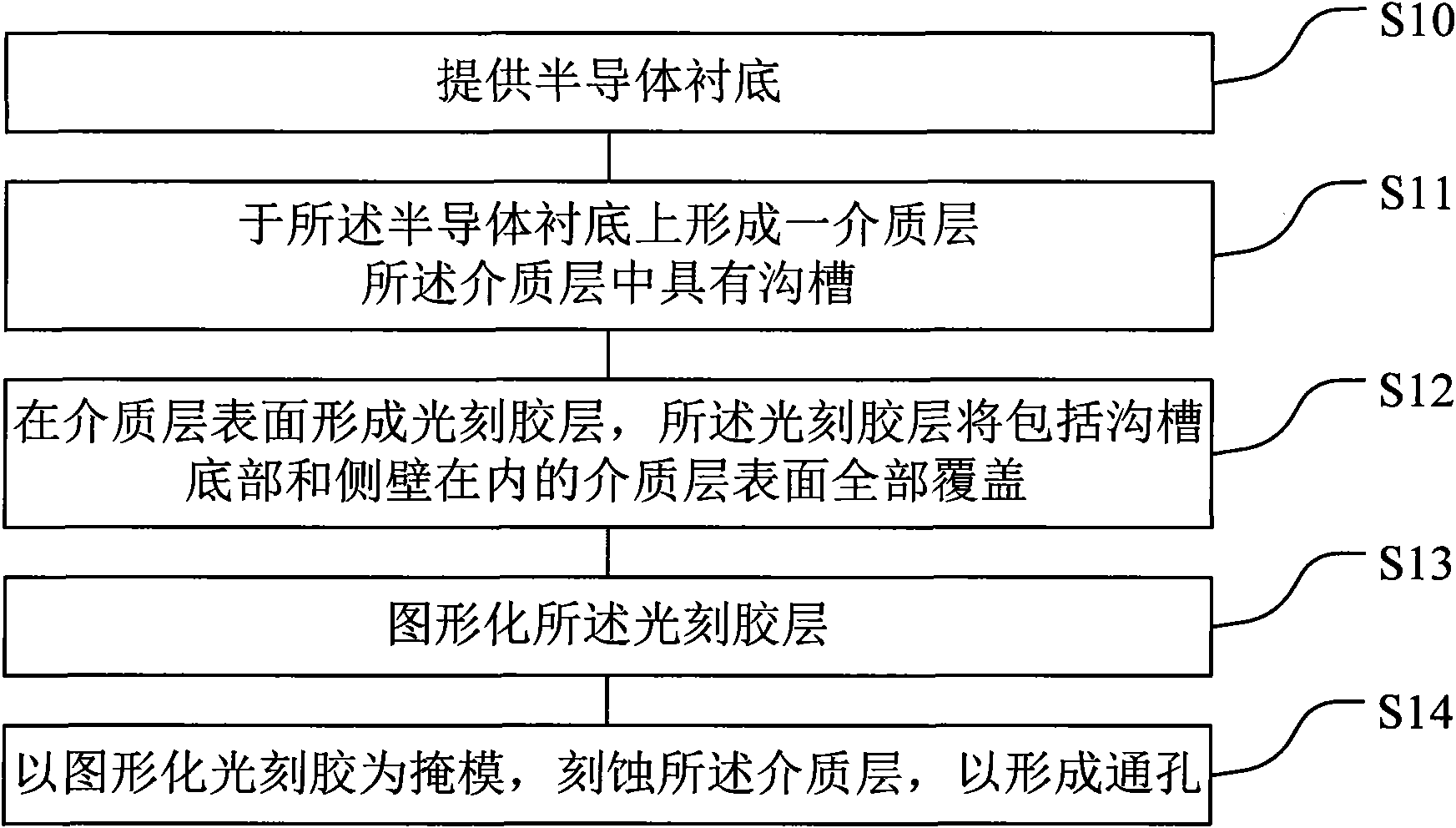

[0026] Attached Image 6 Shown is a flow chart of the implementation steps of this specific embodiment, including the following steps: step S20, providing a semiconductor substrate; step S21, forming a dielectric layer on the semiconductor substrate, the dielectric layer having trenches; S22, forming an anti-reflection layer on the surface of the dielectric layer, the anti-reflection layer covering the bottom and sidewalls of the trench; step S23, forming a photoresist layer on the surface of the anti-reflection layer; step S24, patterning the photoresist layer Step S25, using the patterned photoresist layer as a mask to etch the anti-reflection layer and the dielectric layer.

[0027] Attached Figure 7 Attached Picture 11 Shown is a schematic diagram of the proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com