Method for forming semiconductor device

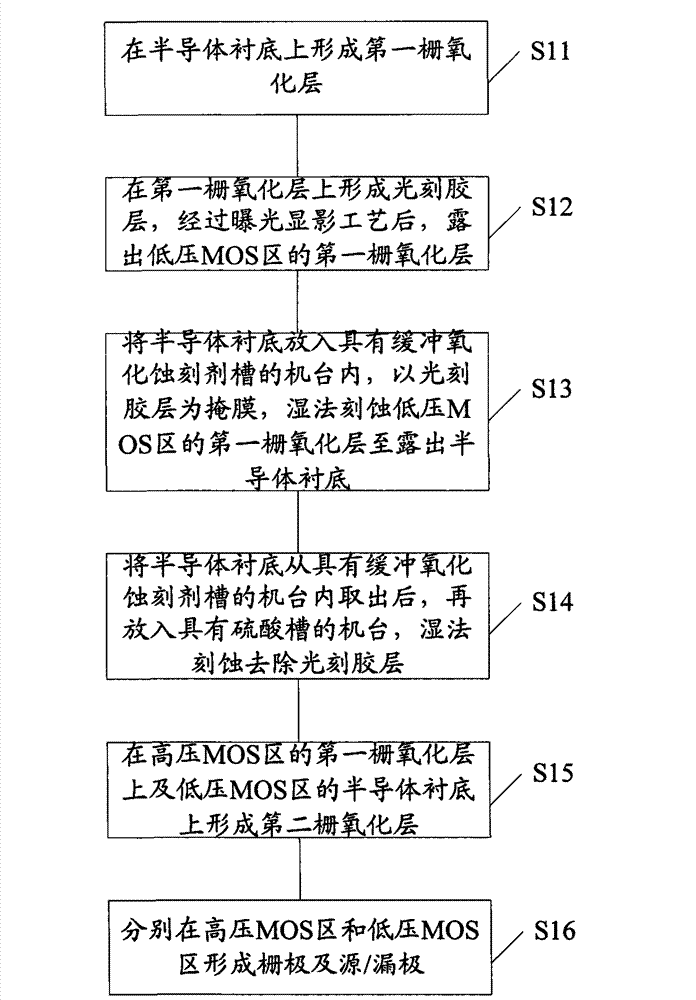

A semiconductor and device technology, applied in the field of semiconductor device formation, can solve problems such as low efficiency, long production time, and inability to remove photoresist, and achieve the effect of improving etching efficiency and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

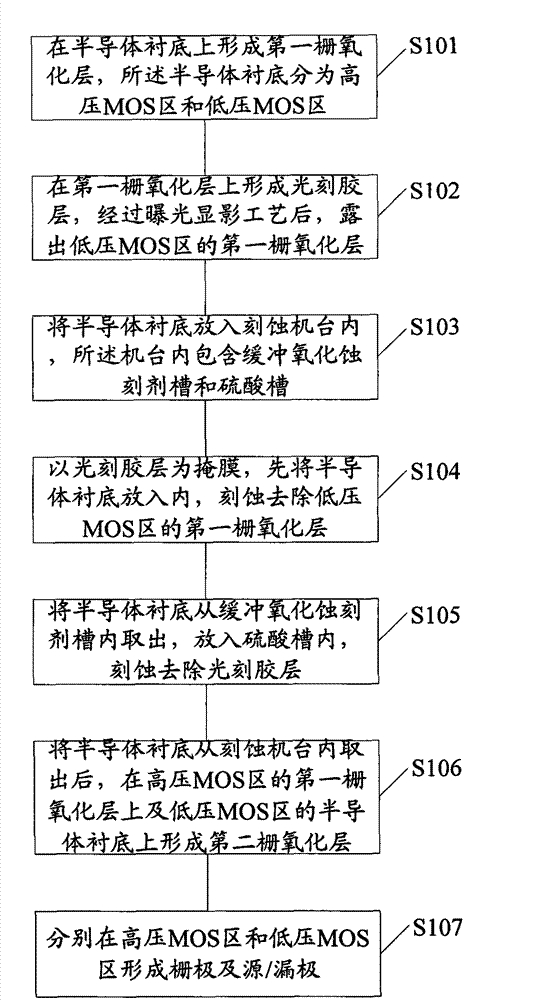

[0016] The essence of the present invention is to put the semiconductor substrate into the etching machine, which contains a buffered oxidation etchant tank and a sulfuric acid tank; after the first gate oxide layer is etched, it is not necessary to remove the semiconductor substrate from the The photoresist layer can be removed only by transferring the semiconductor substrate from the buffered oxidation etchant tank to the sulfuric acid tank in the same machine. The problem that photoresist residues cannot be removed due to too long waiting time between cleaning with buffered oxide etchant and cleaning with sulfuric acid is solved, time is saved, and etching efficiency is improved.

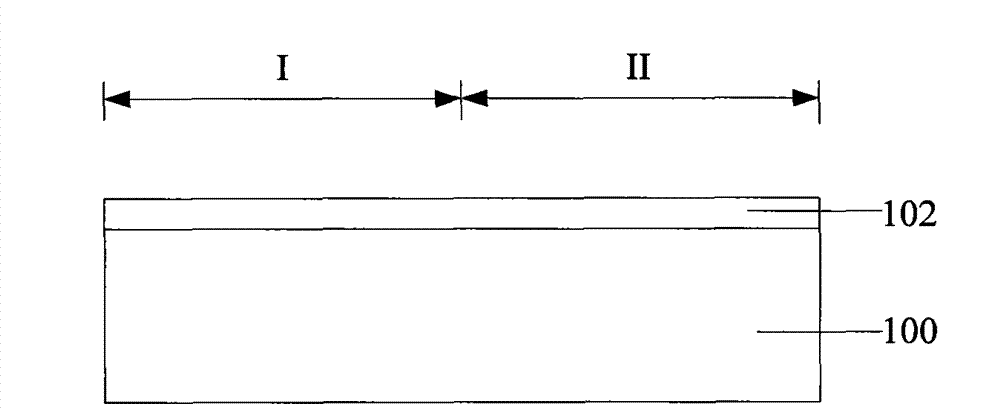

[0017] The process flow of the present invention to form a semiconductor device including a high-voltage MOS transistor and a low-voltage MOS transistor is as follows figure 2 As shown: step S101 is executed to form a first gate oxide layer on the semiconductor substrate, and the semiconductor s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com