A kind of cleaning method of heavy-duty gas turbine combustor nozzle

A technology for gas turbines and combustion chambers, applied to cleaning methods and appliances, chemical instruments and methods, and cleaning hollow objects, etc., can solve the problems of foreign matter clogging and difficult discharge, and achieve the effects of simple assembly, reasonable structure, and guaranteed nozzle flow path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

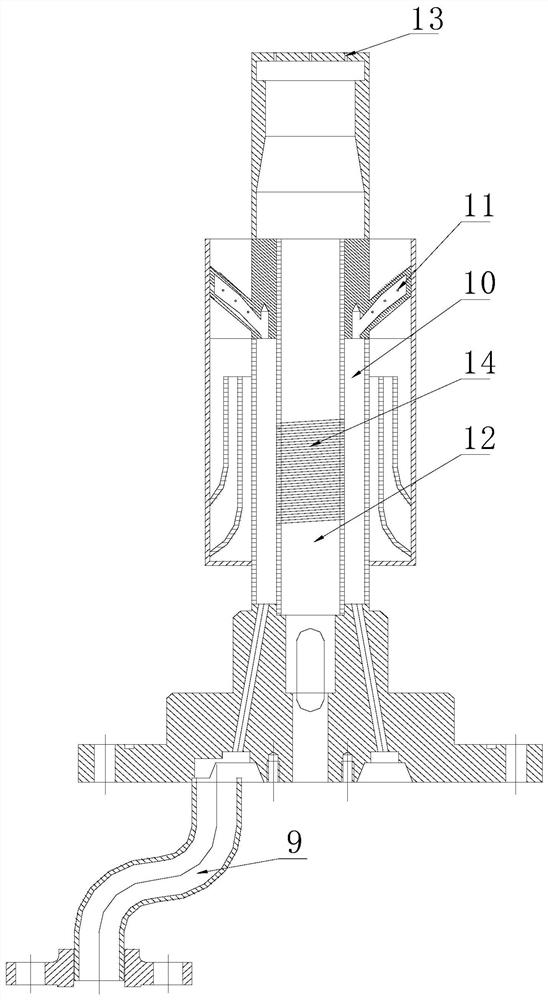

[0019] Embodiment 1: The cleaning method for a heavy-duty gas turbine combustor nozzle in this embodiment is carried out according to the following steps:

[0020] 1. Backflush the heavy-duty gas turbine combustor nozzle using the combustor nozzle cleaning component:

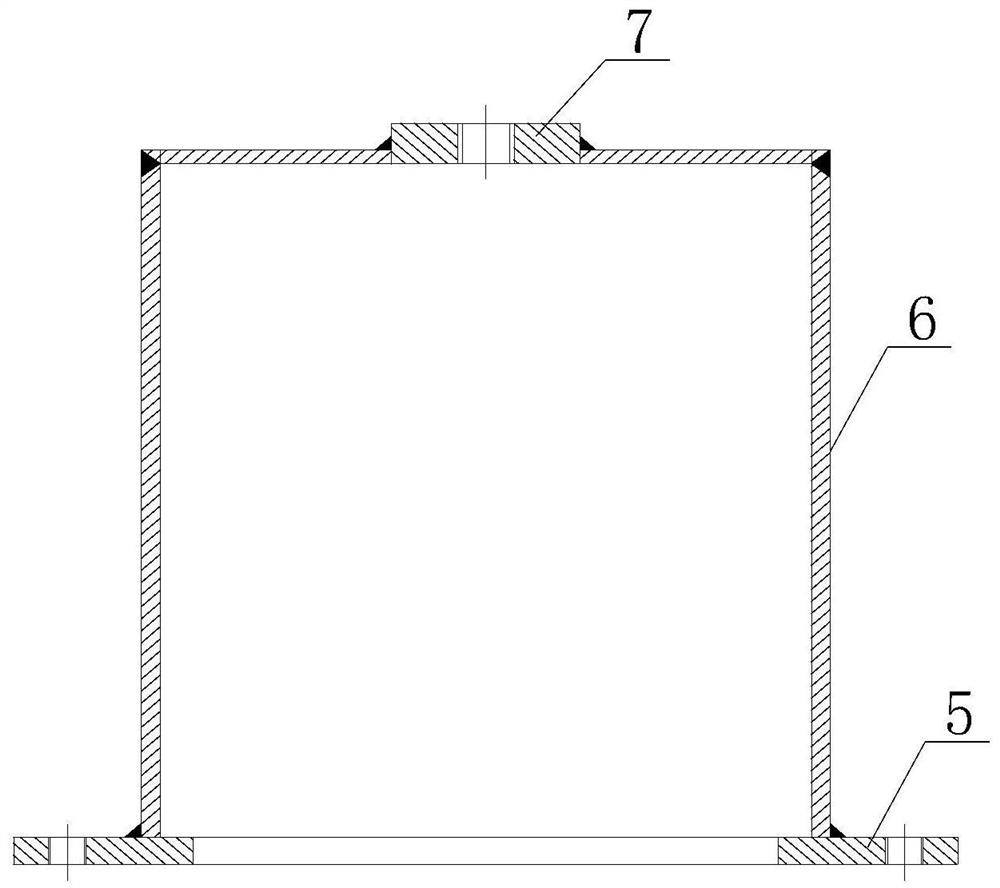

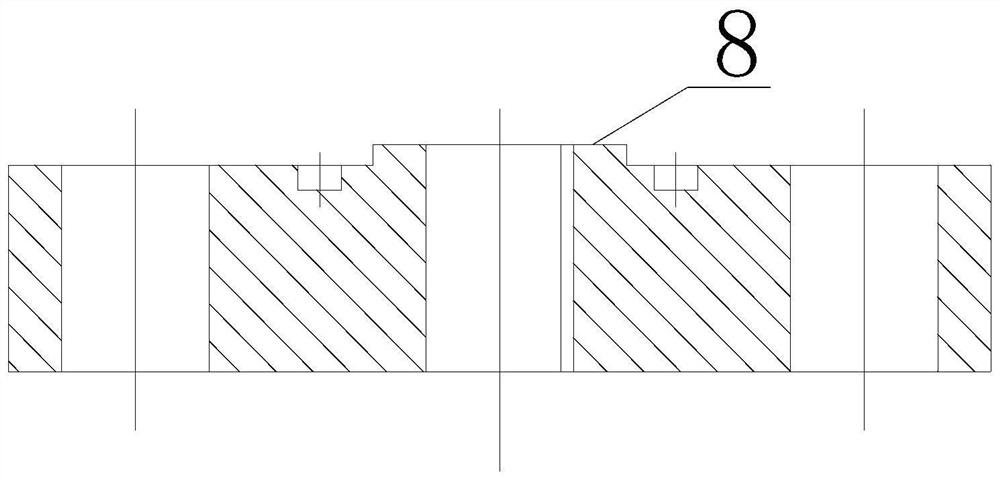

[0021] The combustion chamber nozzle cleaning assembly is composed of a cylinder block 1, a gas pipe flange 2 and an air pipe flange cover 3; the cylinder block 1 is composed of a cylinder block flange 5, a cylindrical cylinder wall 6 and a water inlet flange 7 One end of the cylinder wall 6 is open, the other end of the cylinder wall 6 is provided with a bottom plate, the water inlet flange 7 is arranged on the outer wall of the open end of the cylinder wall 6, and the water inlet flange 7 is arranged on the center of the bottom plate of the cylinder wall 6 ; The center of the gas pipe flange 2 is a threaded hole, and the threaded hole is provided with a plug 4;

[0022] First, put the cylinder block 1 for cle...

specific Embodiment approach 2

[0030] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the cylinder flange 5, the cylinder wall 6 and the water inlet flange 7 are connected by welding.

specific Embodiment approach 3

[0031] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that an O-ring is provided between the cylinder flange 5 and the flange at the rear end of the nozzle body of the combustion chamber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com