A Laser Selective Melting Forming Method for Nozzle Shell

A technology of laser selective melting and nozzle housing, which is applied in the field of additive manufacturing, can solve the problem that metal powder cannot be removed, achieve the effect of reducing the number of parts and increasing cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in further detail below in conjunction with accompanying drawing:

[0031] The method of the present invention comprises the following steps:

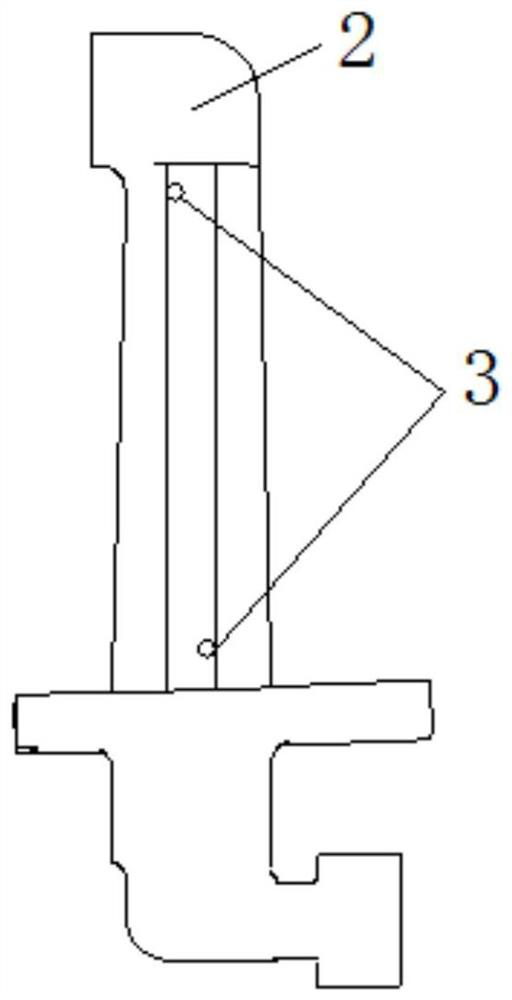

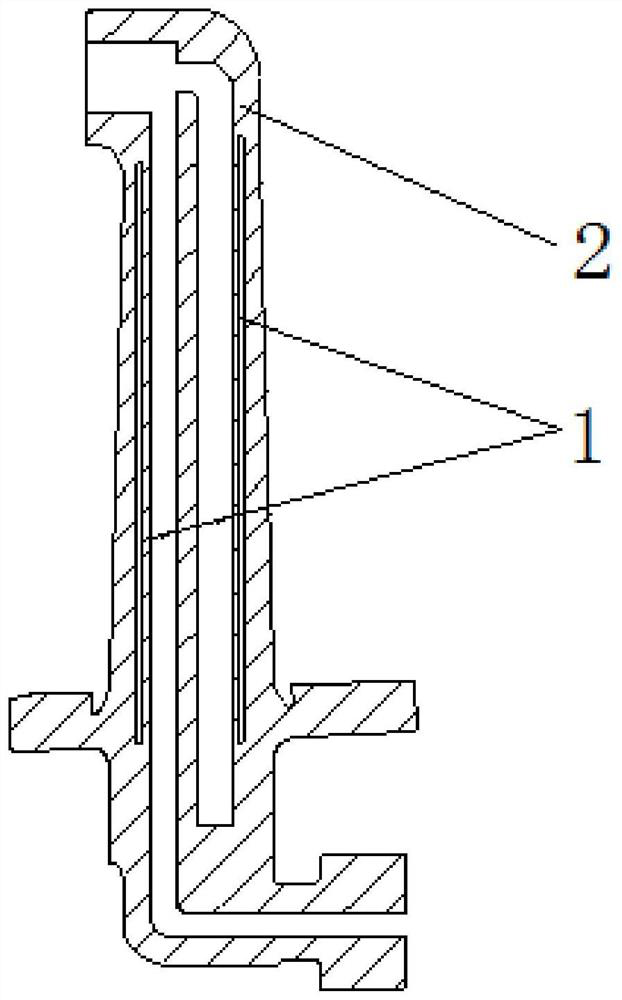

[0032] Step 1, the aviation fuel nozzle housing 2 with a closed cavity structure is formed by laser selective melting and additive manufacturing, such as Figure 1-2 As shown, the forming direction of the nozzle housing 2 parts is placed vertically.

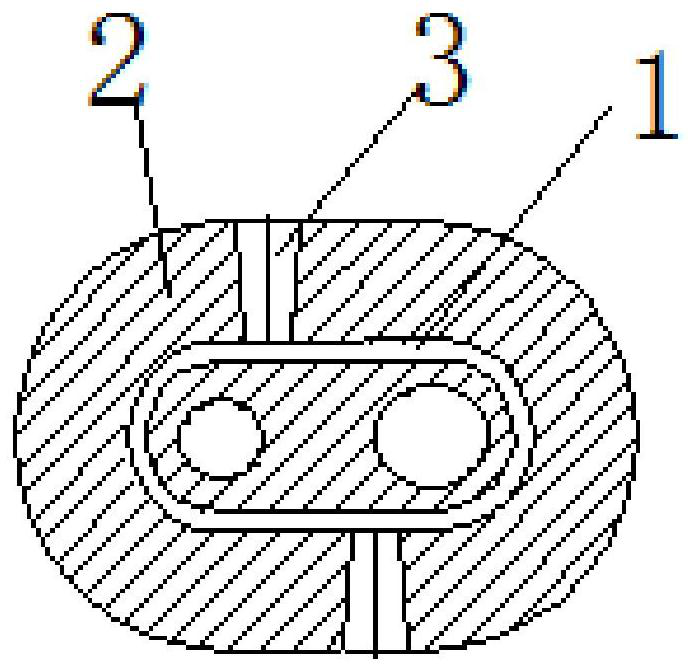

[0033] The nozzle housing 2 includes a nozzle head, a rod and a mounting plate connected in sequence. The bottom of the mounting plate is respectively provided with an oil inlet port of the main oil circuit and an oil inlet port of the auxiliary oil circuit. They are perpendicular to each other and are respectively connected to two independent oil passages. The two independent oil passages are arranged inside the rod. The nozzle head is provided with a nozzle opening. The two independent oil passages converge to the nozzle opening. A completely c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com