Modified hyperbranched polymer (HBP), proton exchange membrane prepared by using same and preparation method of proton exchange membrane

A hyperbranched polymer, proton exchange membrane technology, used in electrochemical generators, climate sustainability, final product manufacturing, etc., to solve problems such as low proton conduction rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

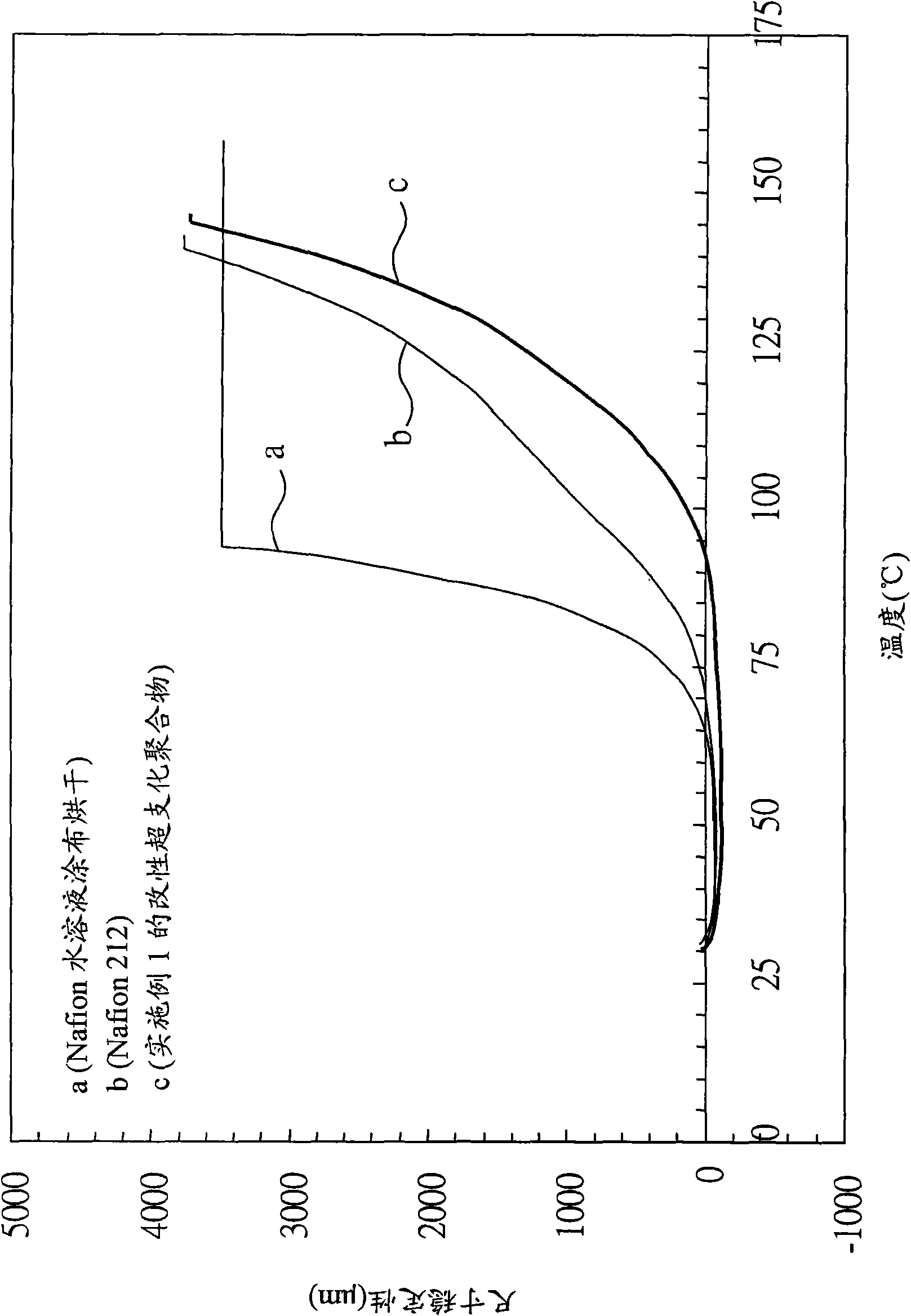

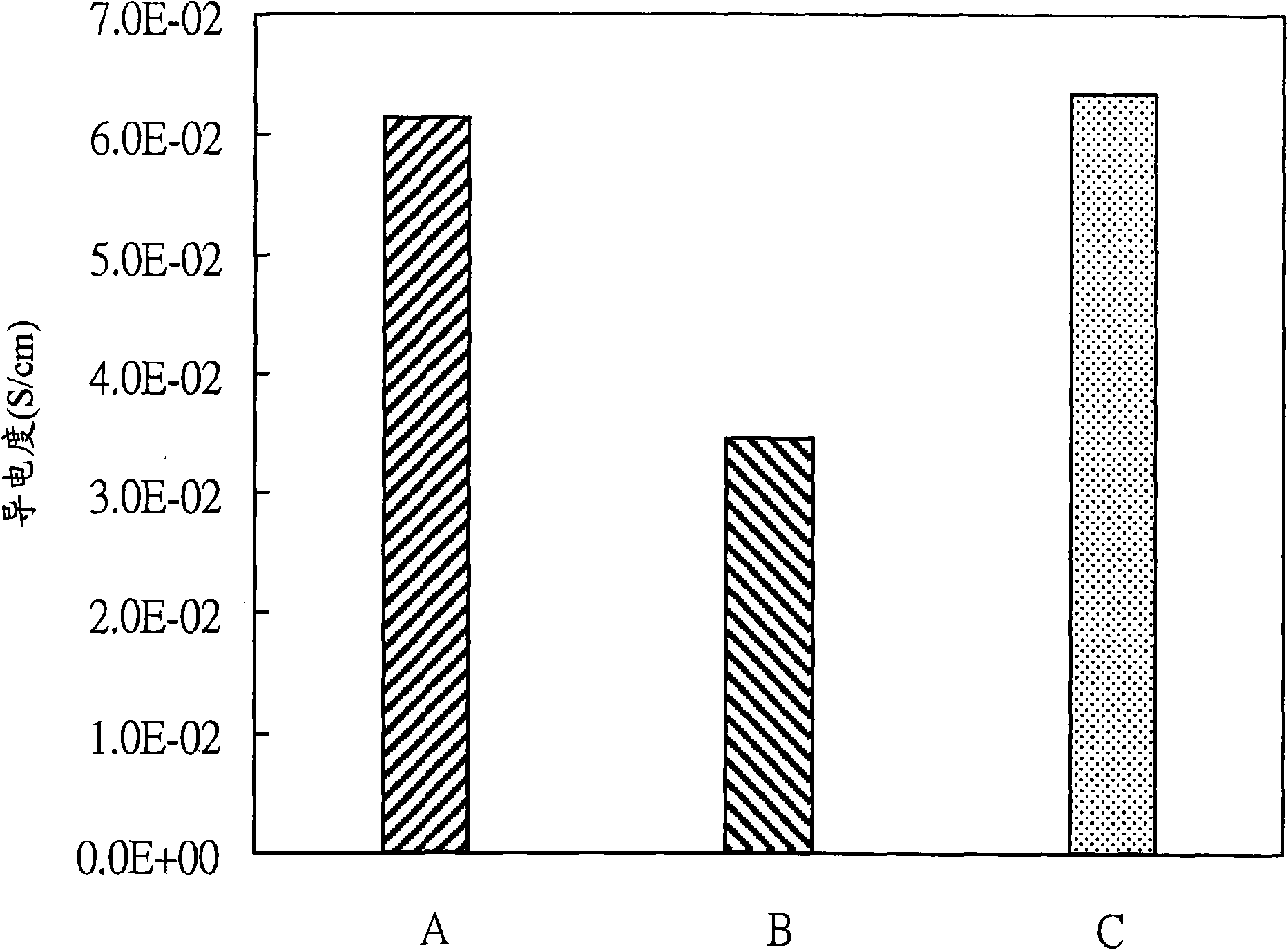

[0040] [Example: Manufacturing method of proton exchange membrane]

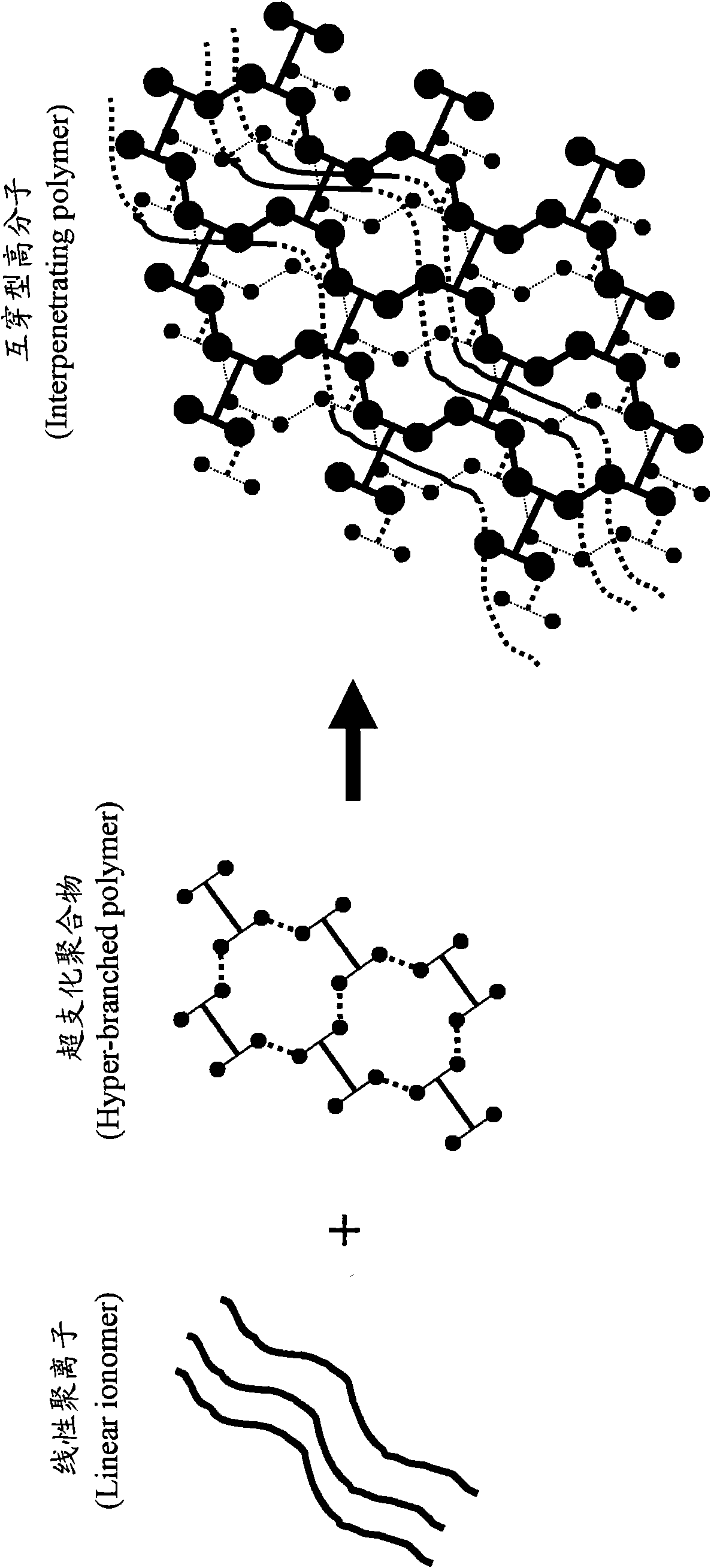

[0041] The proton exchange membrane manufacturing method proposed in this embodiment mainly forms a hyperbranched polymer by copolymerizing bismaleimide and barbituric acid, and utilizes sodium styrene sulfonate (Sodium4-vinylbenzenesulfonate) to form a hyperbranched polymer. The ends are sulfonated. The steps for producing the proton exchange membrane in the examples are described below.

[0042] Hyperbranched polymers forming a bismaleimide matrix

[0043] Firstly, take an appropriate proportion of bismaleimide and barbituric acid, add γ-butyl lactone, heat to 130°C and react for 4 hours to carry out copolymerization reaction to form a hyperbranched polymer. The structures of bismaleimide and barbituric acid are shown in the aforementioned structural formulas (1) and (2). Wherein, the molar ratio of bismaleimide to barbituric acid is about 10:1 to 1:1.

[0044] In other embodiments of the present inve...

Embodiment 1

[0072] Take 16.967g of BMI (bismaleimide of Formula 3) and 3.3033g of barbituric acid, add 100g of γ-butyl lactone, heat to 130°C and react for 4.5 hours to form a hyperbranched polymer.

[0073]

[0074] Next, take 30 g of Nafion aqueous solution (DE2020CS purchased from DuPont), add 18 g of DMAc solution, heat in a water bath at 60° C., and replace the water and alcohols in the Nafion aqueous solution with DMAc.

[0075] After adding the above-mentioned hyperbranched polymer solution into Nafion's dimethylacetamide solution, it was left standing and heated to 50° C. for 48 hours to form an interpenetrating polymer solution.

[0076] Then add 0.5 parts by weight of sodium styrene sulfonate (Sodium4-vinylbenzenesulfonate) with the following structure to 99.5 parts by weight of the interpenetrating polymer solution, and leave it at room temperature for 24 hours to connect sodium styrene sulfonate to the hyperbranched polymer part of the end, forming an interpenetrating polym...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com