Total mixed ration (TMR) fermented feed for cow replacement cattle using soybean straws as raw materials and preparation thereof

A technology for fermenting feed and soybean straw, applied in animal feed, animal feed, application and other directions, can solve the problems of insufficient understanding of the nutritional value of soybean straw, affecting the ecological environment of river transportation, poor palatability of soybean straw, etc. The effect of preventing ion imbalance and facilitating transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

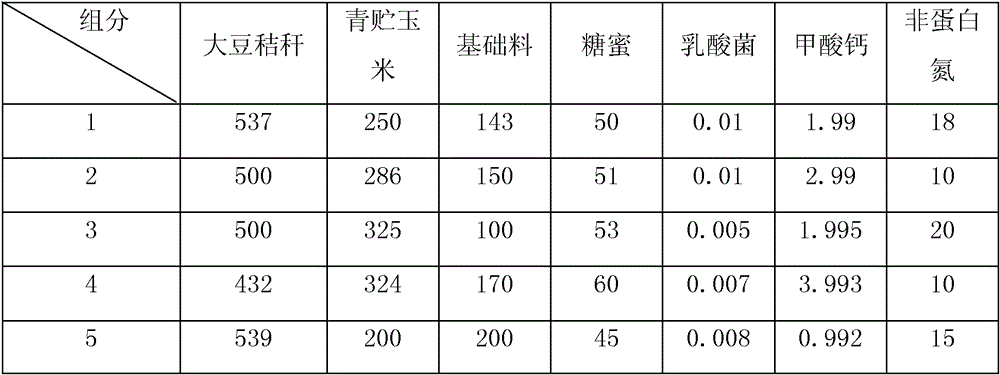

[0054]

[0055] Add the components of the above-mentioned fermented feed materials 1-5 into the TMR mixer, stir and mix evenly, adjust the water content to 45wt%-55wt% of the total feed mass; pour it into a polyethylene film vacuum bag, and meet the requirements after vacuuming Density (500-800 kg / m 3 ), the bag is sealed and finished; after 10-50 days of fermentation, it can be fed to back cattle.

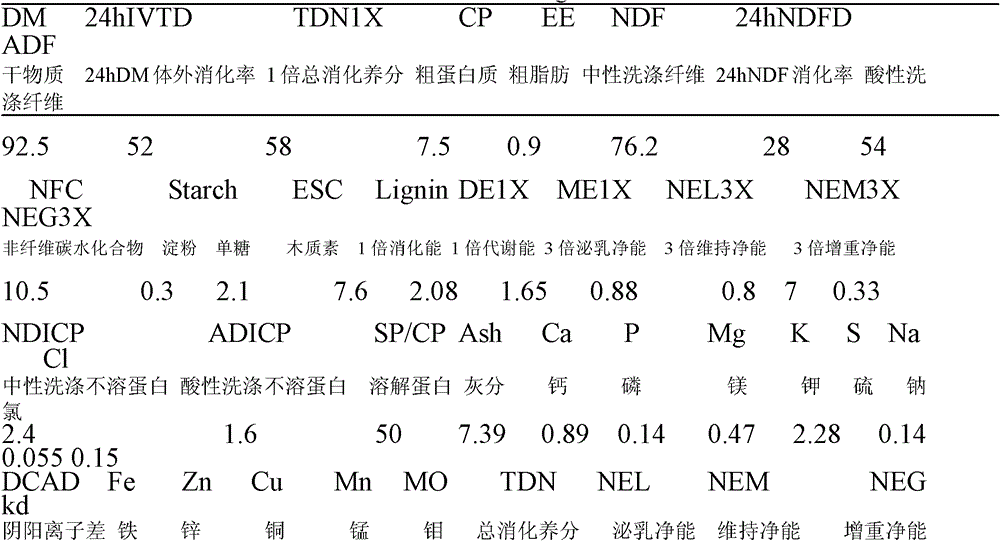

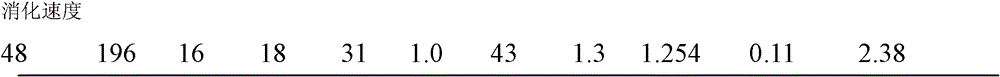

[0056] Each group of raw materials in the above-mentioned embodiment is feed grade, and is conventional commercially available product, and information is as follows:

[0057] Soybean straw: Shanghai Dingniu Feed Co., Ltd.

[0058] Silage corn: Shanghai Dingniu Feed Co., Ltd.

[0059] Basic material: Shanghai Dingniu Feed Co., Ltd.

[0060] Molasses: Shanghai Mengxin Animal Husbandry Co., Ltd.

[0061] Fermentation agent: French Laman company

[0062] Antifungal agent: Shanghai Luyuan Fine Chemical Co., Ltd.

[0063] Urea Shanghai Wujing Chemical Plant

Embodiment 2

[0065] Using the first fermented feed material in Example 1, after adding each component into a TMR mixer and mixing evenly, the moisture is adjusted to 50wt% of the total mass of the feed; poured into a polyethylene film vacuum bag, and vacuumized to reach Required density (500-800 kg / m 3 ), finished after the bag was sealed; fermented for 25 days.

[0066] Laboratory analysis: The soybean stalks fermented for 0 days and 20 days were sampled to detect the content of dry matter, crude protein, crude fat, ADF, NDF and crude ash.

[0067] All detected raw data were statistically analyzed by SPSS17.0. The test results showed that compared with soybean straw feed fermented for 20 days, dry matter decreased by 0.8%, crude protein increased by 0.2%, crude fat significantly increased by 0.23%, ADF significantly increased by 1.2%, NDF decreased by 1%, and crude Ash content does not change.

Embodiment 3

[0069] Use the 2nd kind of fermented feed raw material in the embodiment 1, after each component is joined in the TMR blender and stirs and mixes evenly, the moisture content is adjusted to 50wt% of the total mass of the feed; Fill in the polyethylene film vacuum bag, reach after vacuumizing Required density (500-800 kg / m 3 ), finished after the bag was sealed; fermented for 20 days.

[0070] Laboratory analysis: The soybean stalks fermented for 0 days and 20 days were sampled to detect the content of dry matter, crude protein, crude fat, ADF, NDF and crude ash.

[0071] All detected raw data were statistically analyzed by SPSS17.0. The test results showed that compared with soybean straw feed fermented for 20 days, dry matter decreased by 1.5%, crude protein increased by 1.2%, crude fat significantly increased by 1.56%, ADF significantly increased by 3.5%, NDF decreased by 1.2%, and crude Ash content does not change.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com