Chain-type circular fresh sheet jelly machine

A round, fresh powder technology, applied in food forming, food science, application, etc., can solve the problems of non-extensibility, low machine speed, and large machine volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A preferred embodiment is given below, and the technical solution of the present invention is more clearly and completely described in conjunction with the accompanying drawings.

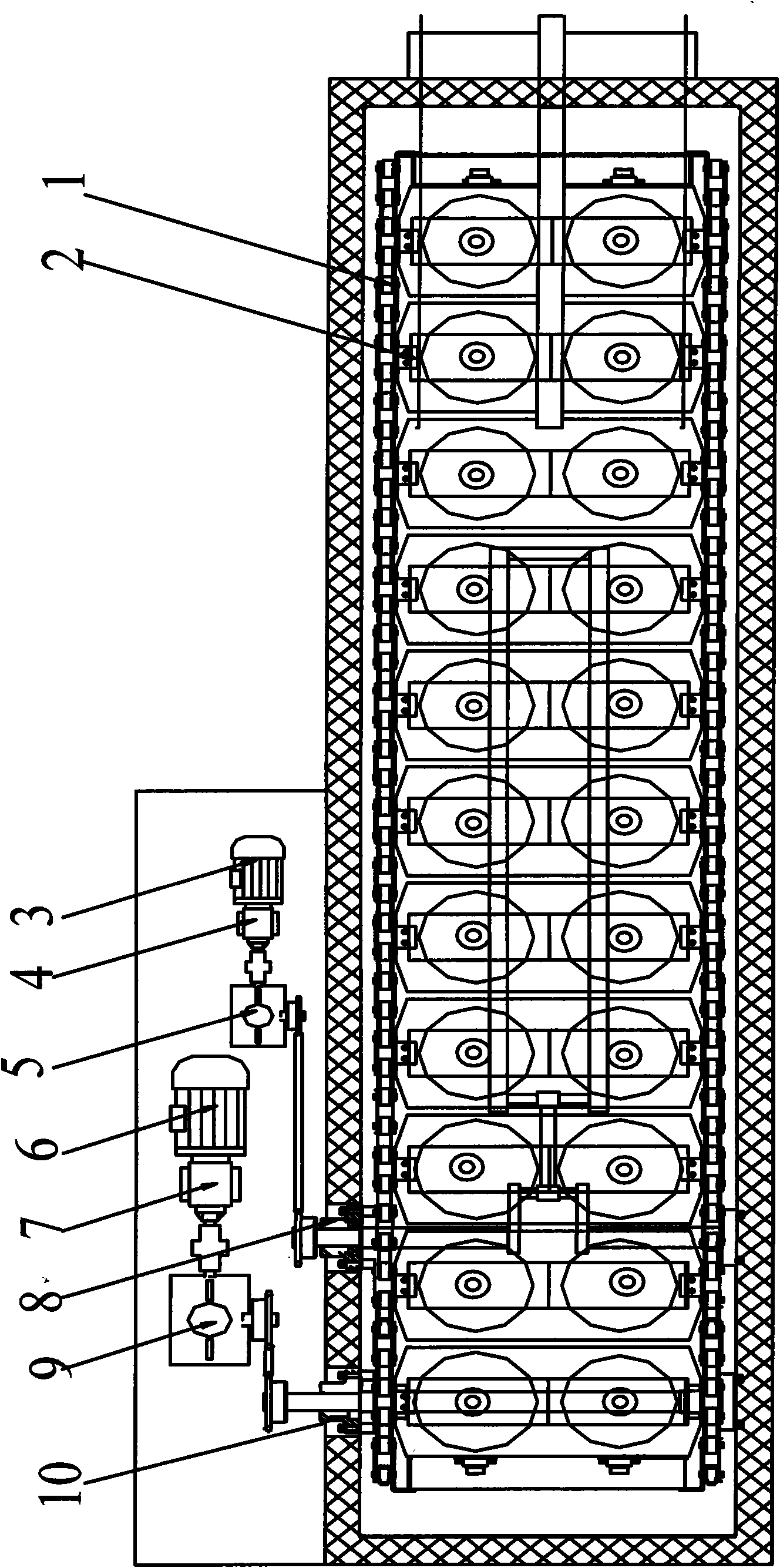

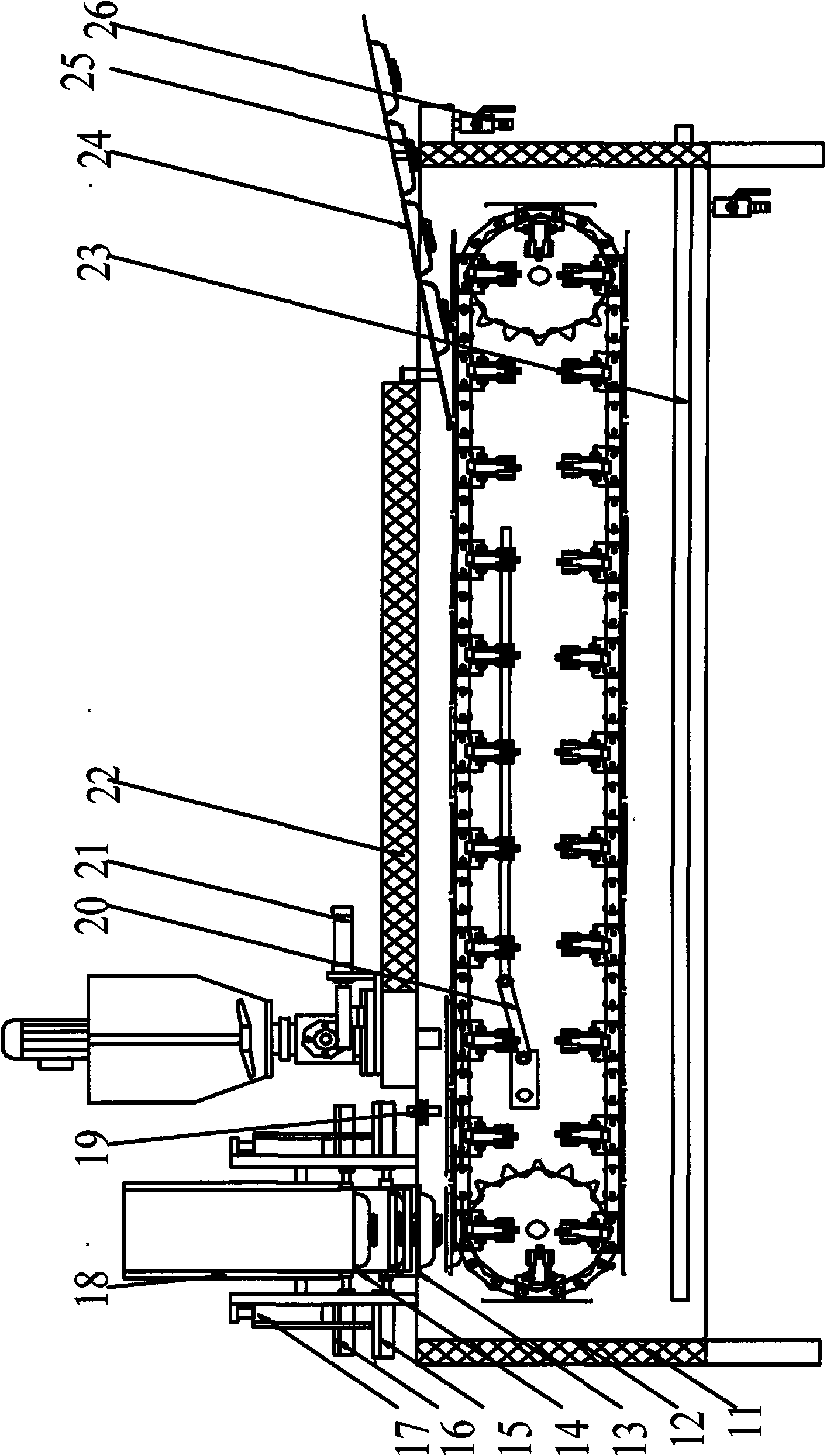

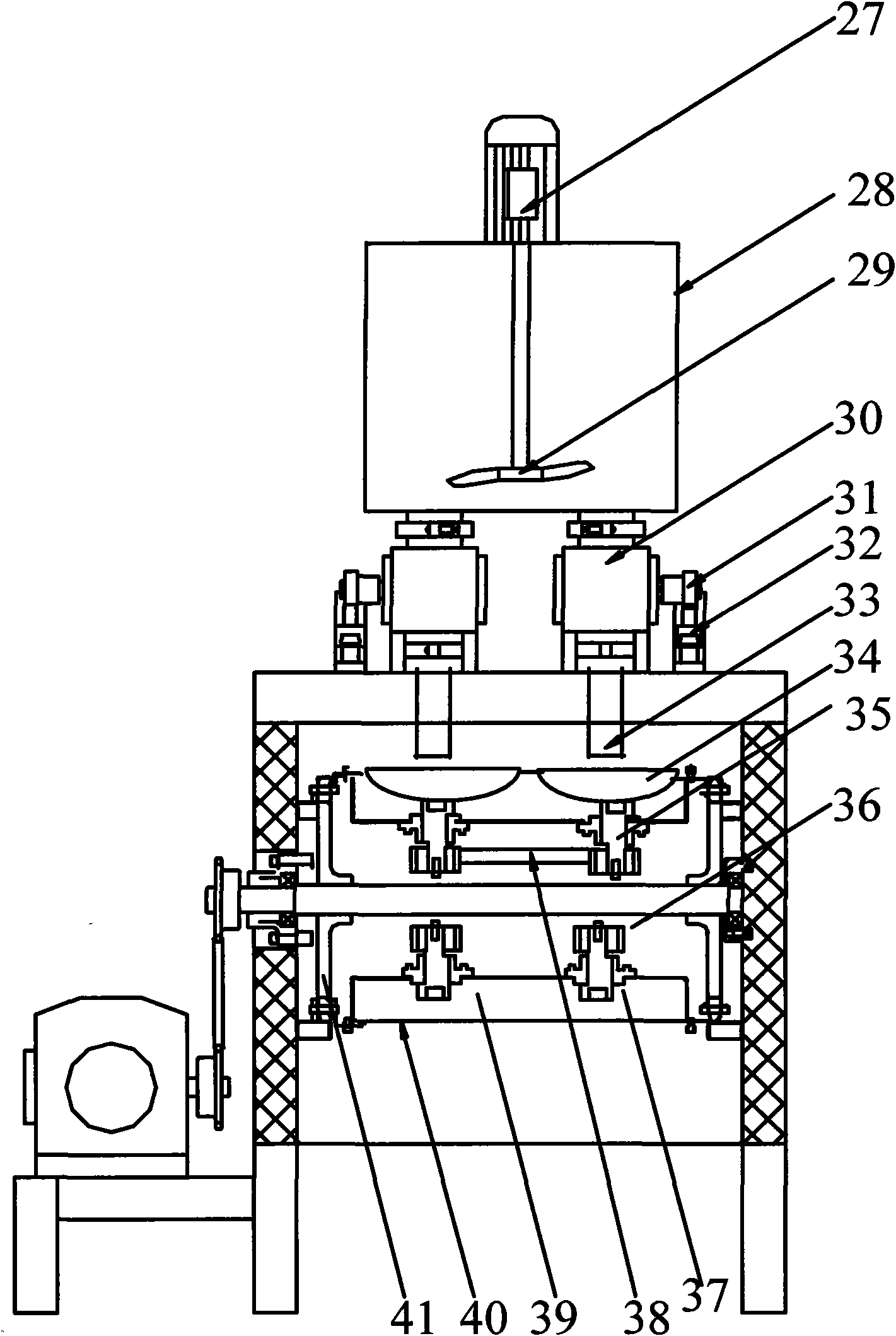

[0017] Such as Figure 1 to Figure 3 As shown, the chain-type round fresh vermicelli machine of the present invention comprises a conveying chain 1, a chain attachment plate 2, a first motor 3, a first electromagnetic clutch brake 4, a first speed reducer 5, a second motor 6, and a second electromagnetic clutch brake 7. Disk rotation bearing seat 8, second reducer 9, conveyor sprocket bearing seat 10, body box 12, upper plate frame 13, pallet frame 14, upper plate cylinder 15, pallet cylinder 16, upper plate lift cylinder 17 , vermicelli forming disk fixing frame 18, measuring disc photoelectric eye 19, disc rotation driving linkage 20, rotary valve driving cylinder 21, box cover 22, steam pipe 23, disc output track 24, vermicelli forming disc 25, overflow port 26 , stirring motor 27, powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com