Slipper and machining method thereof

A processing method, the technology of slippers, applied in the direction of shoe uppers, footwear, footwear, etc., can solve the problems of harming human health, occupying a large volume, inconvenient to carry, etc., and achieve the effect of saving space, simple processing, and convenient portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention will be further described.

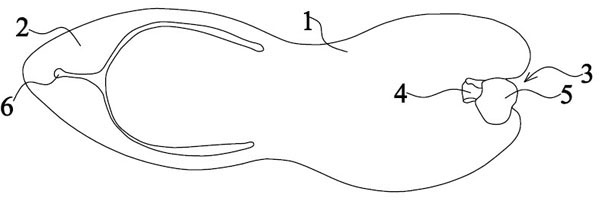

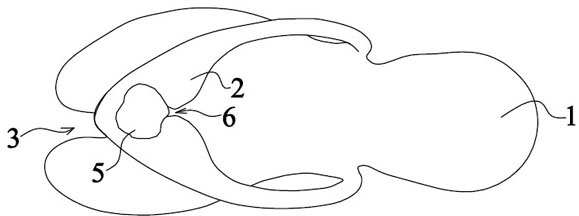

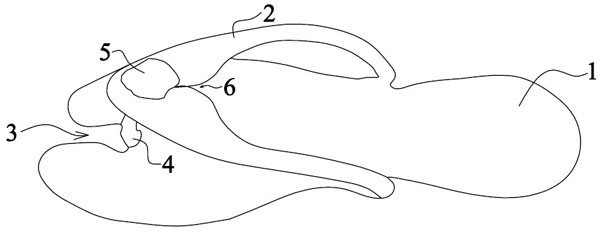

[0014] Such as figure 1 The slippers shown in the present invention include a sole 1 and an upper. According to people's habits, a groove 3 is formed between the big toe and the second toe of the sole, and a front strap 4 is arranged at the root of the groove 3. The connection between the front strap 4 and the root of the groove 3 can be processed with a material with better toughness to improve the durability of the product; the other end of the front strap 4 is provided with a convex cap 5, and on both sides of the rear of the sole 1 The rear strap 2 is connected, and the middle part of the rear strap 2 is provided with a card slot 6 to engage with the convex cap of the front strap. The shape of the rear strap matches the outer contour of the rear part of the sole.

[0015] Through the above structure, when the slippers are in normal use, the front drawstring and the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com