Method for processing double-angle hole of body of oil well logging instrument

A petroleum logging and dual-angle technology, which is applied in the process design of petroleum logging instruments and in the field of processing double-angle holes in the body of petroleum logging instruments, can solve the problems of high processing cost and difficult process design of double-angle holes, and achieve Good versatility and cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

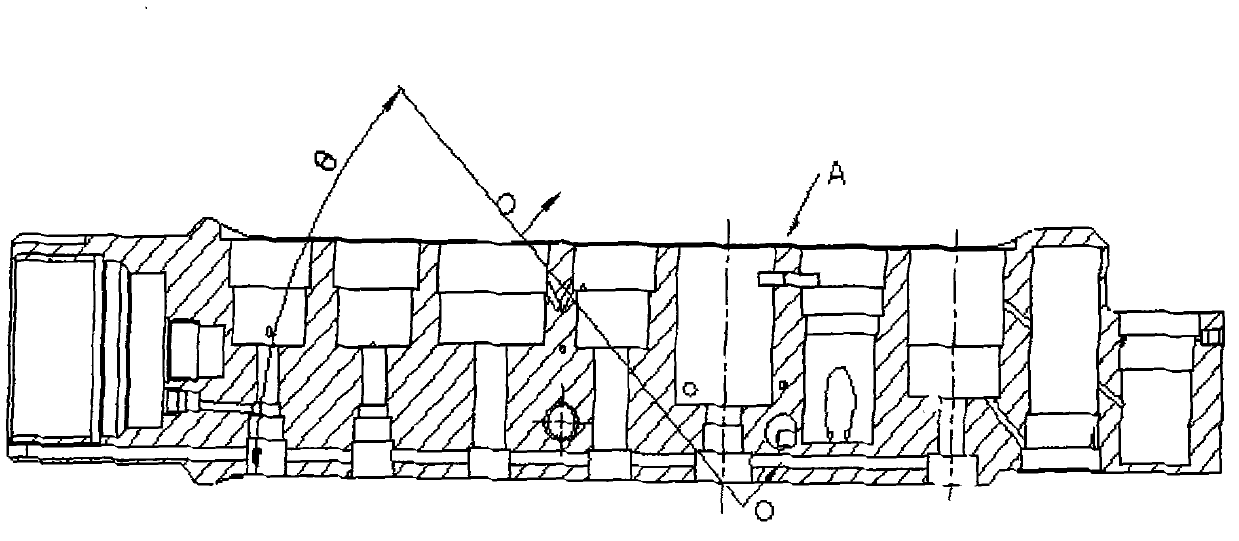

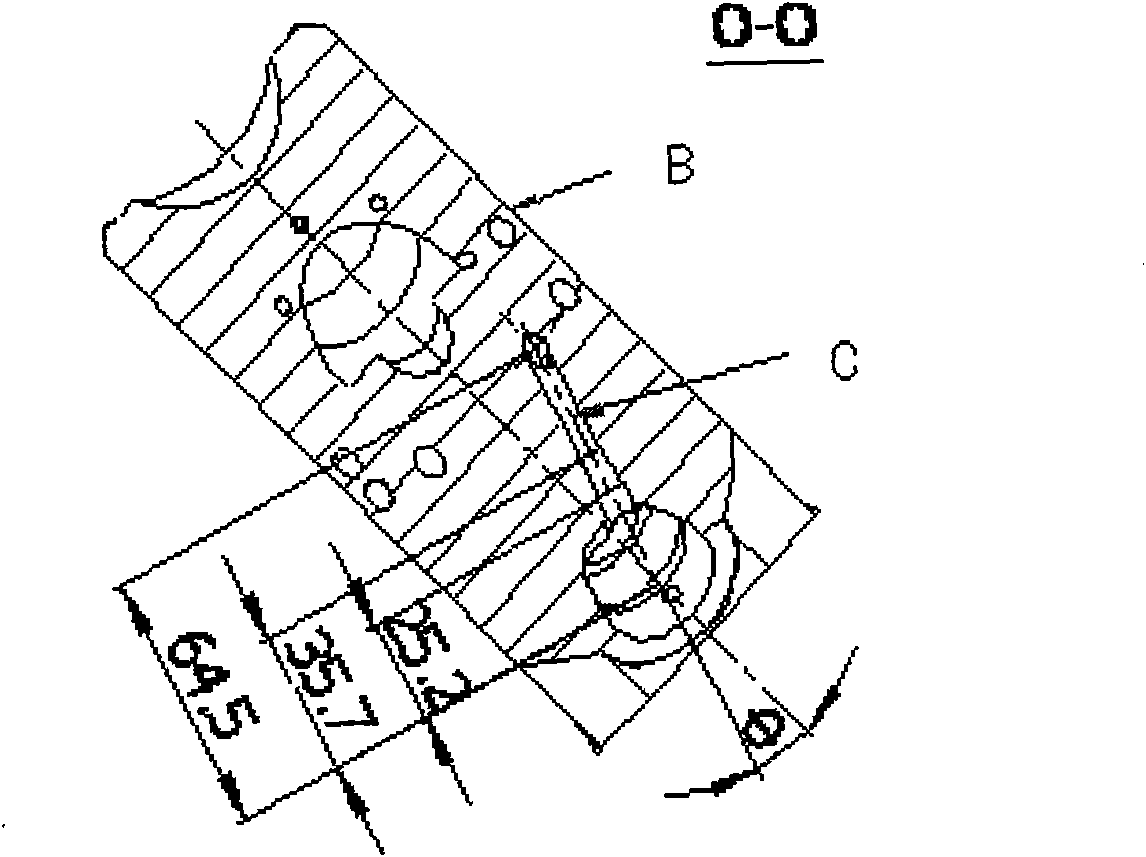

[0034] Utilize the inventive method to process "repetitive formation tester lower body" (see Figure 5 ) Machining of four double-angle holes on AX6, AX7, AX8, and AX9:

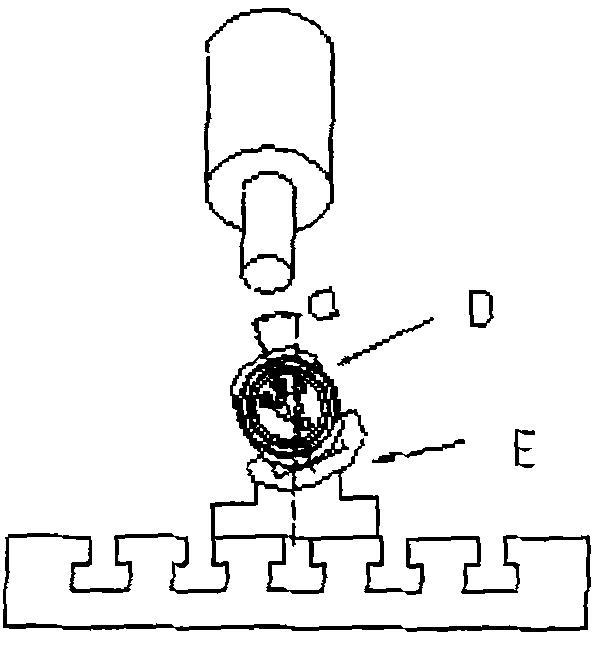

[0035] The workpiece is positioned and clamped by the workbench and the tilting vise to the lower body. Taking the AX7 double-angle hole as an example, the processing process is explained according to the following steps:

[0036] Step 1: Establish a coordinate system in an orthogonal state on the body, and draw a line at the cutting point (279,0) of the double-angle hole on the drawing as the origin of the coordinate system;

[0037] Step 2: Clamp the body in a tilting vise to ensure that the straightness of the positive jaw and the top surface of the body in the X direction is less than 0.03mm;

[0038] Step 3: Turn the tilting vise to the process angle α:

[0039] in: is the design ang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Straightness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com