Method for firstly processing support seat with an X-shaped frame and secondly welding

The technology of a support seat and a support ring is applied in the processing field of the main body of the excavator walking frame, which can solve the problems affecting the efficiency of mass production, the difficulty of processing large excavators, and the long time of clamping and processing, so as to improve work efficiency and save Equipment, the effect of reducing processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

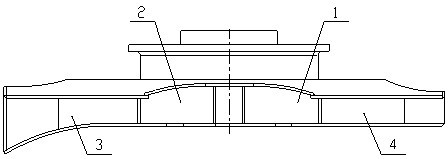

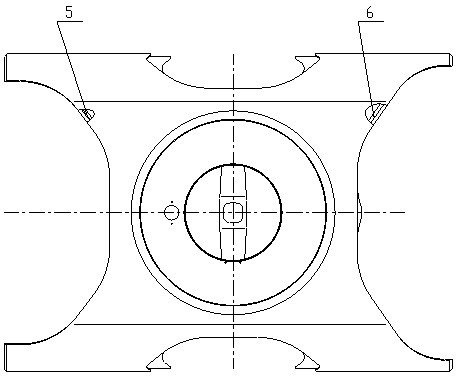

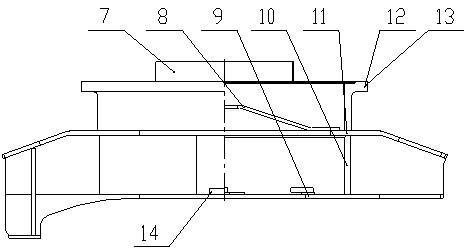

[0012] The invention provides a method of welding the support seat of an X frame after processing first, combining Figure 1 to Figure 3 , the steps are: directly clamp the X-frame support seat 13 on the machine tool for processing, after processing, with the middle front rib plate 1, the middle rear rib plate 2, the rear right rib plate 3, the front right rib plate 4, and the rear left rib plate 5. Front left rib plate 6, oil pool ring 7, joint mounting plate 8, lower cover plate 9, ring 10, upper cover plate 11, support ring 12, support seat 13 and circular plate 14 are welded into a whole, and the order of welding It is as follows: firstly weld the weld seam between the ring 10 and each rib plate, so that the upper cover plate 11 and the lower cover plate 9 are longitudinally fixed without longitudinal deformation, and then weld the weld seam between the upper cover plate 11 and each rib plate, symmetrical welding Two people are welded at the same time to reduce welding defo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com