Automatic packing type electric arc synthetic furnace

A technology of automatic filling and synthesis furnace, which is applied in the direction of nanotechnology, can solve the problems of environmental pollution, operator workload, etc., and achieve the effect of avoiding cumbersome procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

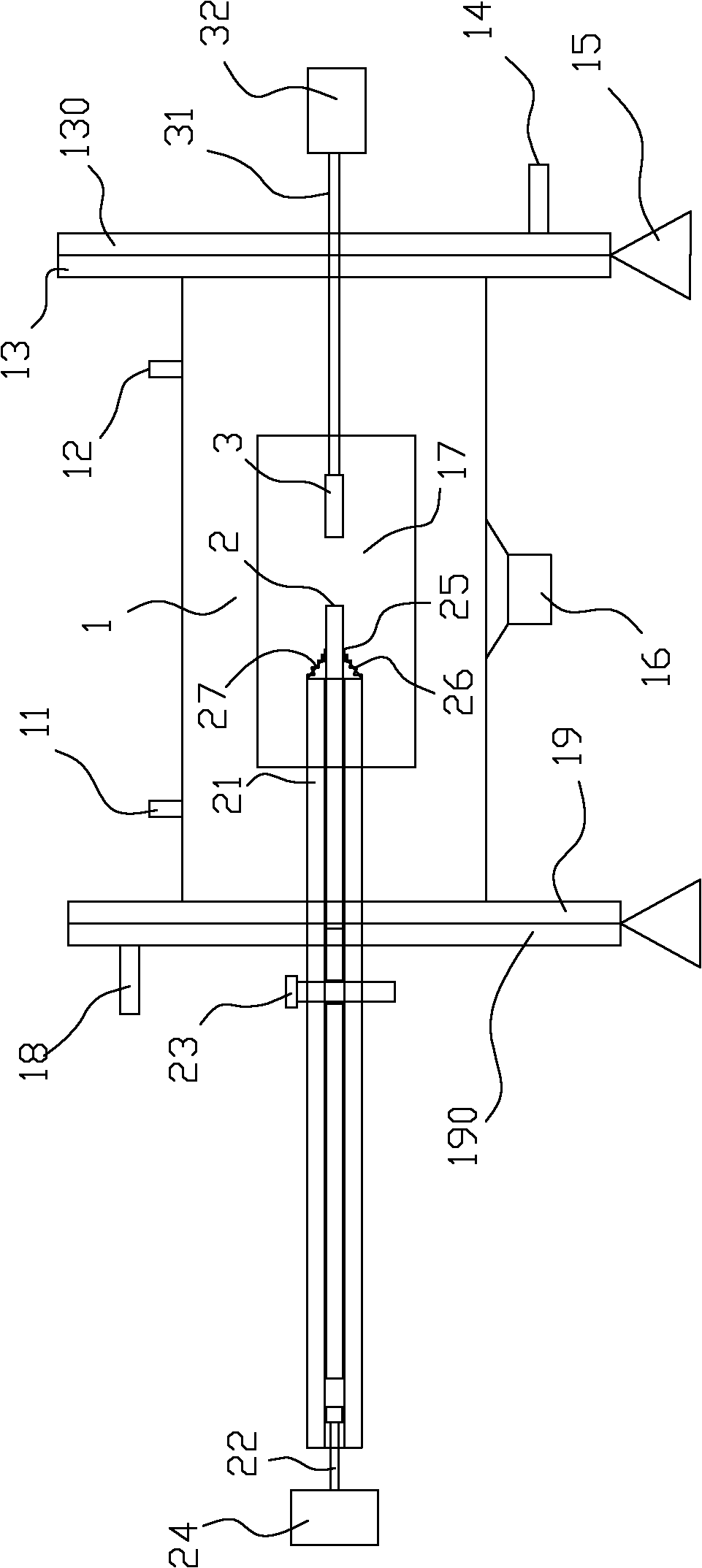

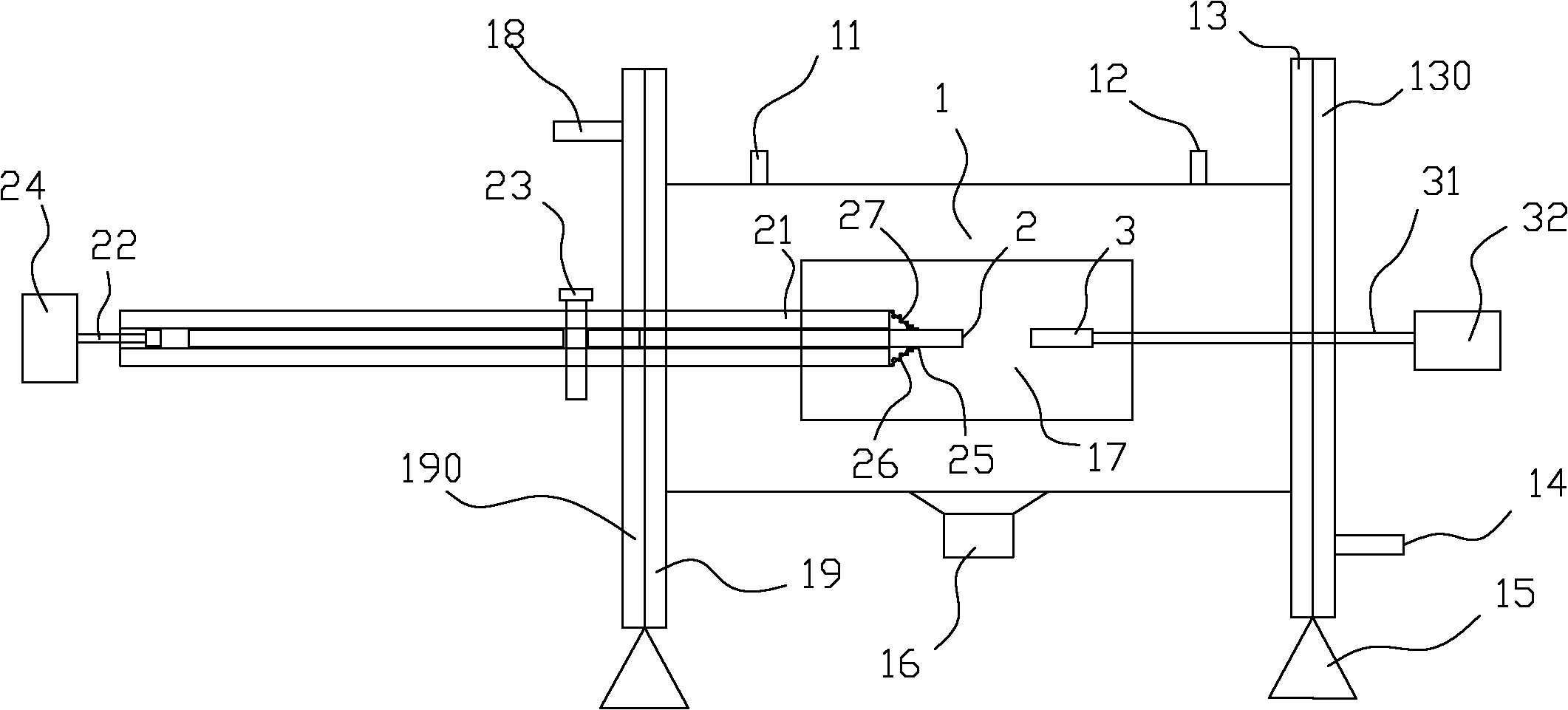

[0019] The anode sampling sleeve 21 of this preferred embodiment is located at the inner end of the furnace body 1 and is provided with a fixing clip, which includes two clips 25 symmetrically arranged for directly clamping the anode graphite rod 2, and the two clips 25 Connect to the end of the anode sampling sleeve 21 through a compression spring 26 respectively, the compression springs 26 are sleeved on a guide rod 27 to prevent the compression spring 26 from being skewed when stretching, and one end of the guide rod 27 is fixed on the anode sampling sleeve Sleeve 21. The anode push rod 22 can directly push the left end of the anode graphite rod 2 between the two clips 25 , and use the elastic force of the compression spring 26 to clamp and fix the anode graphite rod 2 . In other embodiments, if the gap between the anode graphite rod and the inner wall of the anode sampling sleeve is small, the end of the anode sampling sleeve can also be used to support the anode graphite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com