Preparation method of fullerene

A fullerene and solvent technology, applied in the field of fullerene preparation, can solve the problems of increasing the cost of heat preservation and constant pressure, increasing heat preservation, constant pressure, affecting the treatment effect, etc., avoiding chemical changes, improving production efficiency, and avoiding chemical changes. Effects of dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be described in detail below. It should be noted that the embodiments described here are for illustration only, and are not intended to limit the present invention.

[0017] First, briefly introduce the equipment used in the method for preparing fullerenes of the present invention.

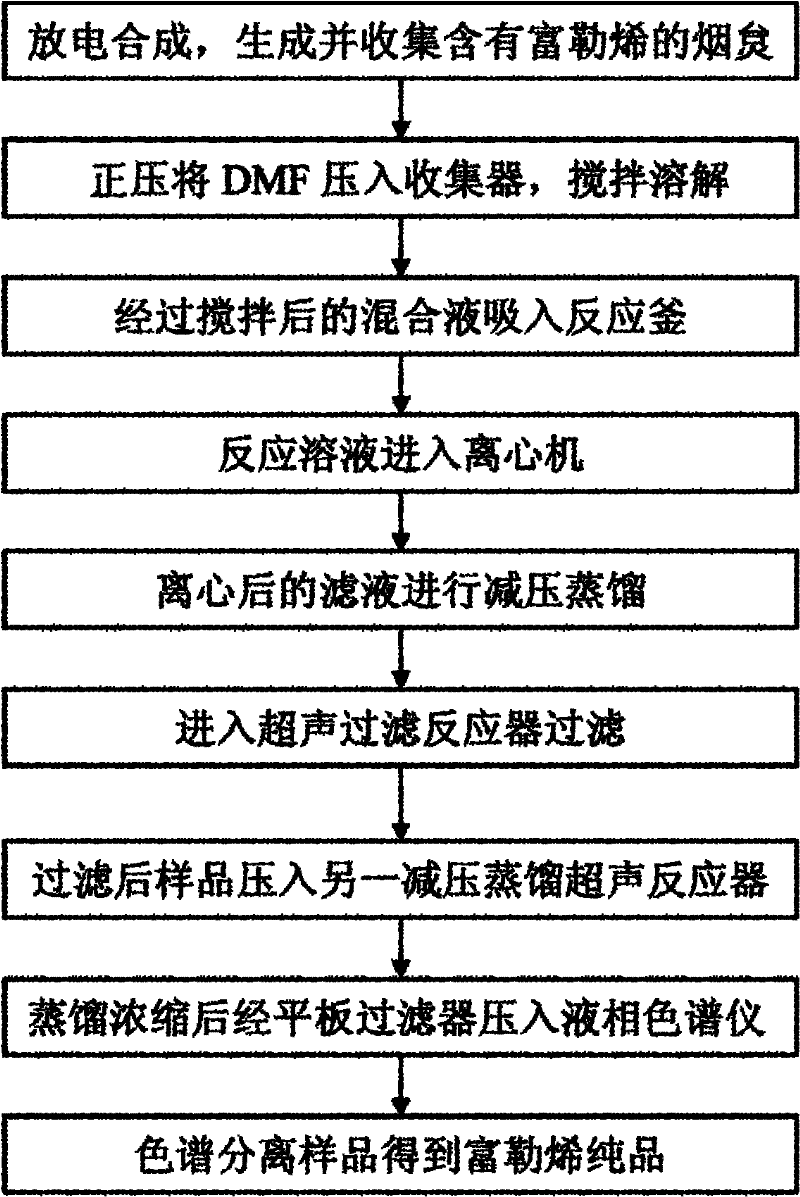

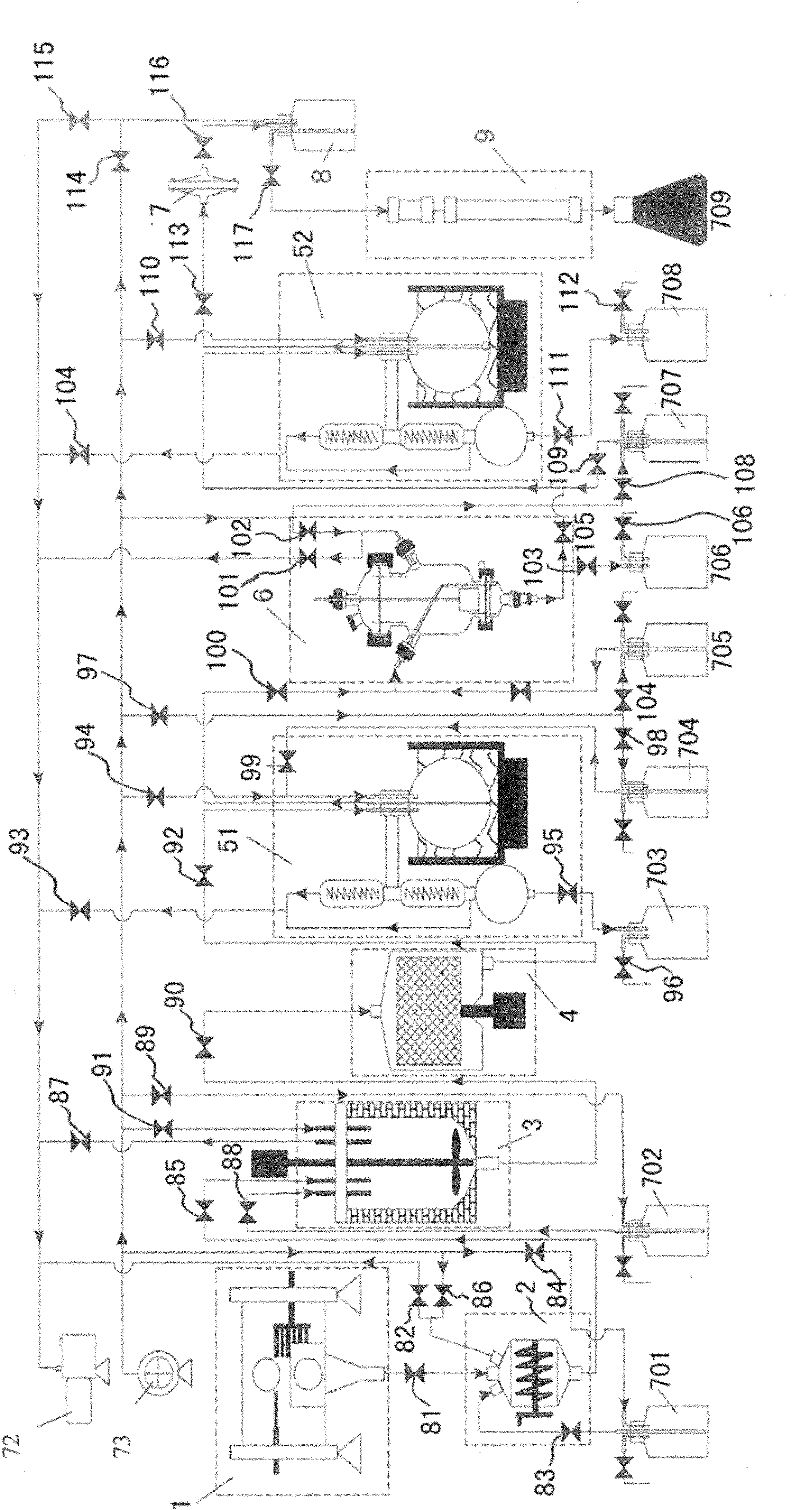

[0018] refer to figure 1 and figure 2 The main components of the device used in the preparation method of fullerenes of the present invention include a synthesis furnace 1, a collector 2, a reactor 3, a centrifuge 4, vacuum distillation ultrasonic reactors 51, 52, an ultrasonic filter reactor 6, and a flat filter 7. Sample bottle 8, high performance liquid chromatograph 9, vacuum pump 72 and air pump 73.

[0019] Each of these components can accomplish the following:

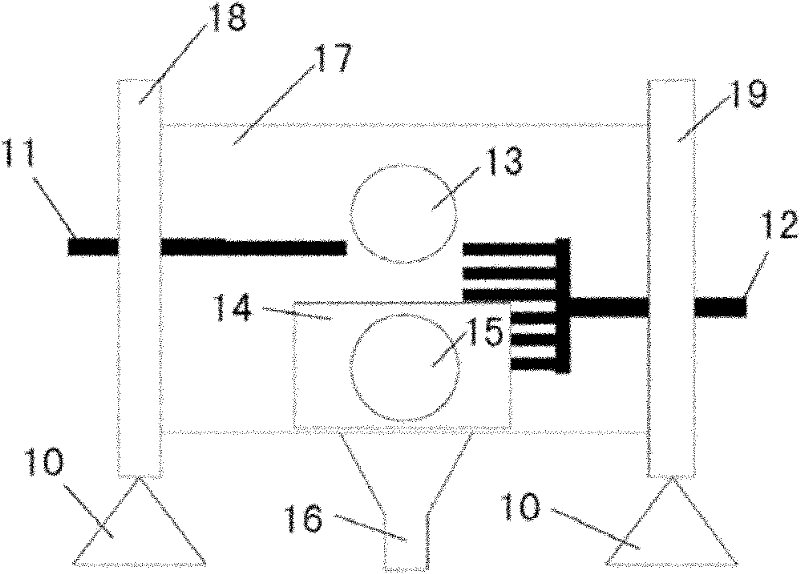

[0020] Synthesis furnace 1 is used for synthesizing soot containing fullerenes; image 3 It is the basic structural schematic diagram of synthesis furnace 1, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com